San Joaquin basin is scene of new effort to evaluate EOR in Monterey

An important new effort is under way to evaluate enhanced oil recovery through carbon dioxide flooding in the prolific Monterey formation of the San Joaquin basin, southern California.

The combined reservoir characterization/pilot EOR project is being conducted by Chevron USA, with the support of the US Department of Energy (DOE), as part of its Class III (slope and basin reservoir) Oil Field Demonstration initiative.

If fully successful, the project may well have enormous implications for future recovery options in the basin, one of the richest petroleum provinces of the lower 48. Recovery of hundreds of millions of barrels may be at stake.

The Monterey formation is well-known as a huge regional reservoir in the San Joaquin, with as much as 12 billion bbl original oil in place. Most of that is contained in diatomaceous shales with low matrix permeability.

Recoveries have typically been no more than 4-8%, in spite of waterflooding, acidizing, and hydraulic fracturing. As a result, the Monterey is considered to be significantly under exploited. Though poor recovery is known to be tied to the unique nature of the reservoir rocks, the precise factors responsible remain poorly understood.

It is the specific goal of the new study to address this situation by:

- Characterizing in detail the factors that govern low recovery;

- Establishing benchmark criteria that will help identify EOR opportunities in Monterey reservoirs; and

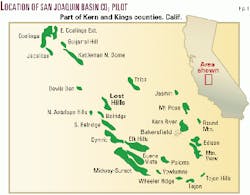

- Using these results to site, design, and evaluate a pilot CO2 flood in the basin where such large fields as Buena Vista Hills, Elk Hills, South and North Belridge, and Lost Hills are located (Fig. 1).

To date, the project has had considerable success in achieving the first two stated goals as a result of advanced reservoir characterization and simulation studies performed in Buena Vista Hills field. On the basis of this work, a demonstration site in Lost Hills field has been selected for the pilot flood.

This article presents a brief review of results gained from this work. It is believed that, once completed, the project will provide an essential collection of public-domain information that operators can use to improve production in various portions of the San Joaquin basin.

General reservoir character

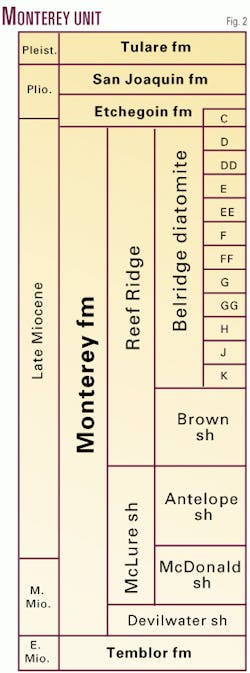

The Monterey formation consists of a thick, upper Miocene-lower Pliocene succession of deepwater diatomaceous shales interbedded with sporadic turbidite sandstones and hemipelagic shale beds (Fig. 2).

The diatomites, including cherts and porcelanites, are frequently laminated and exhibit normal grading or other evidence of cyclic deposition.1 These rocks reflect cool, quiet-water conditions in which abundant upwelling supported large, seasonal diatom blooms.

Such conditions ensued with a change in tectonic setting between late Oligocene and late Miocene time, when the San Joaquin forearc basin became progressively closed off due to emplacement of a large crustal block (Salinian Block) along its western flank, with related deformation and uplift.2

Reservoirs of the Monterey formation can be described in terms of three lithologic components: biogenic silica, clay, and sandstone/siltstone. Proportions among these different components can vary significantly over a given interval. Mineralogically, moreover, siliceous lithologies display an important diagenetic change from opal-A, an unstructured mineral that preserves original diatom frustules, to opal-CT, which is more structured, dense, and porcelanic.

This phase transition takes place at low temperatures and shallow depths (~2,500 ft, 40-50° C.), within the range of depths at which the Monterey is commonly productive in the southern San Joaquin basin (800-4,000 ft). Matrix porosities and, more importantly, permeabilities both decrease significantly as a result of the transition from opal-A to opal-CT.

The Monterey is most productive in its upper part, including the Belridge diatomite, Brown shale, and Antelope shale. Reservoir intervals are typified by considerable thicknesses (up to 1,000 ft or more), very high porosities (35-60% for opal-A rocks; 25-32% for opal-CT), and low permeabilities (1-10 md for opal-A, <1 md for opal-CT).

In contrast to their offshore equivalents, e.g., at Point Arguello field, these onshore Monterey reservoirs are not pervasively fractured.

Reservoirs are deformed into a series of large, NW-SE trending, thrust-faulted anticlines along the southwestern portion of the San Joaquin basin. Early analyses of structure in the area interpreted these folds as the result of transpression associated with shear along the San Andreas Fault.3

More recent studies of regional stress, however, show that maximum horizontal compression is oriented perpendicular to the San Andreas4 and that both the general and detailed disposition of fault-fold relationships in the southwestern San Joaquin are most commensurate with a thrust-fold belt model. Data suggest a total of 12-17% crustal shortening in a N35E direction.

Reasons for limited recovery

As a result of the detailed studies performed at Buena Vista Hills field, several reasons emerged to help explain low oil recovery from Monterey reservoirs in the San Joaquin. These include the following:

In addition to these factors, completion practices and limited data collection have also had a role in reducing recovery. Most fields in the southern San Joaquin were discovered early in the 20th century and were produced at high initial rates, causing reservoir pressures to decline rapidly, often below the bubble point.

As an example, original pressures of 2,100 psi in the Antelope shale at Buena Vista Hills fell below 1,400 psi within 10 years; by 1990, this figure had declined to 750 psi.5 Logging, moreover, was minimal and interval evaluation infrequent or rare.

Cores taken prior to 1970 have often been lost; core data acquired through older methods is of limited use. Collection and calibration of all available data at Buena Vista Hills, plus the drilling, coring, and extensive testing of a new "data well," proved invaluable as a source of information for evaluating future recovery possibilities and options.

CO2 flood criteria

Laboratory experiments and reservoir simulations performed at Buena Vista Hills suggest that CO2 flooding can significantly enhanced oil recovery, depending on several criteria. These include: oil saturation; reservoir pressure; injection pressure; vertical and lateral lithologic heterogeneity; and well spacing. Reservoir temperature and oil gravity may also play important roles due to the shallow depths involved, which ensure that CO2 flooding will be an immiscible process.

Criteria related to reservoir character were observed to be inadequately satisfied at Buena Vista Hills.5 6 Recovery in this field has been 6.5% (9 million bbl), leaving an estimated 130 million bbl in place, yet the potential resource is scattered over a thick vertical interval with oil saturations of 20% or less.

Considerably reduced reservoir energy and sporadic natural fracturing also decrease predicted flood performance. While simulated recovery was significant at reservoir pressures of 2,000 psi, it was almost negligible at current pressures.

Lateral changes in reservoir lithology inhibit the displacement of oil toward producers. Reservoir simulation at Buena Vista Hills showed that injection and cycling of CO2 resulted in good mixing of gas and oil, probably due to gravity-driven crossflow from high-permeability sandstones and fractures to low-permeability diatomaceous layers. Yet, even after 10 years, such mixing was pervasive only in the vicinity of the injector well, with large portions of the reservoir non-contacted. Poor conformance between injectors and producers adversely affects mixing of CO2 and oil even over short distances.

Lost Hills field

On the basis of the above criteria, a pilot CO2 flood site was eventually selected in Lost Hills field, roughly 40 miles north of Buena Vista Hills.6

Discovered in 1910, Lost Hills produces from depths of 1,500-2,500 ft along the crestal portion of a large, southeast-plunging anticline interpreted to lie above a ramp thrust fault. Numerous NE-SW oriented normal faults of minor throw (40 ft or less) cut the structure, but do not appear to affect production significantly.

The main reservoir is the Belridge diatomite at the top of the Monterey formation, with subsidiary production from the underlying Brown, Antelope, and McDonald shale members (Fig. 3). The Belridge diatomite is developed on 1.25 to 5-acre spacing and has been subjected to extensive hydraulic fracturing and waterflooding during the past 10-15 years. Despite such aggressive development, cumulative production as of January 2000 was only 135 million bbl, representing 5% of the more than 2.6 billion bbl in place.

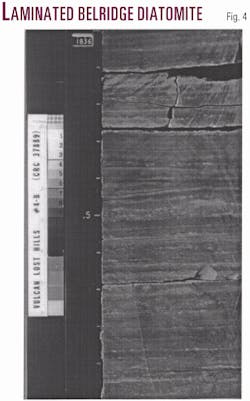

The Belridge diatomite consists of laminated, diatomaceous material (Fig. 4) with an average of about 33% biogenic silica, 36% clay, and 31% silt/sand. Most of the Belridge lies above the opal-A/opal-CT transition (Fig. 3) and produces from the matrix, which has permeabilities of 0.1-10 md, porosities of 35-60%, and oil saturations of 33-62% (avg. 46%).

The total Belridge interval averages about 700 ft thick, with pressures varying from 300 psi at the top to over 1,000 psi at the base. Core observation, in conjunction with newly acquired borehole imaging (Electrical Micro-Imaging) data, indicate 1-3 fractures per 10 ft of vertical interval, with most of these being clay-filled and unrelated in orientation to the current stress regime.

Many of these fractures are interpreted as early, dewatering, and compaction features and do not contribute significantly to fluid flow in the reservoir.

Production from the underlying Brown, Antelope, and McDonald reservoirs is from rocks of opal-CT composition with very low matrix permeabilities and thus depends a good deal on fracturing. Geochemical analyses indicate that the Monterey formation contains 1-6% total organic material and is probably self-sourcing, with thermally mature rocks occurring downdip to the west.

Evaluation for CO2 flood

The target reservoir for the CO2 pilot is the Belridge diatomite in a structurally elevated portion of the field (32-26s-21e).

Based on a review of well test data in the vicinity of the pilot site, it was found that the residual oil saturation to waterflood (i.e., the amount of oil saturation remaining after waterflooding has gone to completion) was on the order of 25-30%.6 This represents a large potential resource (>300 million bbl) for the entire Belridge diatomite reservoir. Geostatistical modeling suggests that similar saturations exist throughout the field.

Simulation and laboratory core-flood results showed injectivity for CO2 at 2-3 times that of water or steam.6 This result was later confirmed by actual injectivity tests run in two wells, the 12-8D and 12-7W, located in the selected pilot site. Recent reservoir simulation runs predicting oil production under four different scenarios-primary recovery (with hydraulic fracturing), waterflooding, steamflooding, and CO2 flooding-have forecast dramatically better performance for gas injection (Fig. 5). During the well injection test, it was observed that short-term production in the 4 pattern producers (11-7B, 11-8D, 12-7, 12-8B) rose by 13% over waterflooding.

Implementation

The pilot flood is being initiated this year (2000) and will be closely monitored for several years thereafter. The pilot location contains a total of 10 active producers and 4 active water injectors, the latter of which will be either converted to gas injectors or else replaced with new injector wells if existing wellbore conditions dictate.

A 2.5-acre, four-pattern configuration will be used rather than the 5/8-acre, inverted five-spot pattern originally planned. This is because the closer spacing resulted in premature CO2 breakthrough during the injectivity tests.

It should be emphasized that the use of CO2 flooding in the San Joaquin basin is largely untried and represents new territory. Thus, a flexible philosophy is being adopted, based initially on experience gained from floods performed in West Texas.

Current plans are to inject gas continuously until an upper gas-to-oil ratio (GOR) limit is reached, at which time injection will be modified to water-alternating-CO2 (WAG) or other system capable of controlling mobility. This approach may be modified, depending on results obtained. It is hoped that large volumes of CO2 can be injected, so that oil can be contacted more quickly and processing made simpler.

Chevron will be injecting between 400 and 2,000 Mcfd (24-118 tons/day) of CO2. The source of the CO2 is BOC Gases in El Segundo, Calif. The CO2 is 99.5% pure and will be trucked from the Los Angeles area to Bakersfield on a daily basis.

Because the timing of any adjustments to injection may be crucial, a comprehensive monitoring plan will be employed. Oil, water, and gas production, as well as reservoir pressure, will be measured continuously. In addition, baseline fluid analyses will be performed and compared with samples collected and analyzed on a weekly basis.

Injection wells will be surveyed in terms of rates, pressures, and vertical injection profiles. Monitoring of the flood front will utilize cased-hole resistivity logs, cross-well seismic, and an electro-magnetic survey run in two newly drilled observation wells with fiberglass casing. A steel-cased pressure observation well was also recently drilled.

A gas-tracer program, along with CO2 and oil geochemical analyses, will be performed to provide new data on permeability trends, breakthrough patterns, and sweep efficiency, with the ultimate objective of continually refining reservoir simulation models to better forecast pilot performance.

Goals and issues

Improving recovery from major reservoirs in well-drilled basins can be said to define an important trend in the domestic U.S. petroleum industry. In many cases, these attempts require a significant investment in new knowledge. Better understanding of reservoir character and dynamics, as well as the detailed controls on productivity, has proven to be essential, particularly where lithology is complex and primary recovery very low.

The effort at Lost Hills provides an excellent example of the type of commitment to new knowledge that has proved necessary. This effort, in fact, seems poised to make a major contribution to petroleum exploitation in the San Joaquin basin. Experience and data that emerge from this effort will go a long way toward determining the possible future of billions of barrels of oil in one of the richest provinces in North America.

References

- Graham, S.A., and Williams, L.A., "Tectonic, depositional and diagenetic history of Monterey formation (Miocene), central San Joaquin basin, Calif.," AAPG Bull., Vol. 69, No. 3, 1985, pp. 385-411.

- Nilsen, T.H., Regional geology of the southwestern San Joaquin basin, Calif.," in Nilsen, T.H., Wylie, A.S., Jr., and Gregory, G.J., eds., "Geology of the Midway-Sunset oil field," AAPG Field Trip Guidebook, 1996, pp. 7-38.

- Harding, T.P., "Tectonic significance and hydrocarbon trapping consequences of sequential folding synchronous with San Andreas faulting, San Joaquin Valley, Calif.," AAPG Bull., Vol. 60, No. 3, 1976, pp. 356-78.

- Zoback, M.D., Zoback, M.L., Mount, V.S., Suppe, J., Eaton, J.P., Healy, J.H., Oppenheimer, D., Resenberg, P., Jones, L., Raleigh, C.B., Wong, I.G., Scotti, O., and Wentworth, C.M., "New evidence on the state of stress of the San Andreas fault system," Science, Vol. 238, 1987, pp. 1,105-11.

- Morea, M.F., "Advanced reservoir characterization in the Antelope shale to establish the viability of CO2 enhanced oil recovery in California's Monterey formation siliceous shales," annual technical progress report, Feb. 7, 1997-Feb. 6, 1998, Project DE-FC22-95BC14938, National Petroleum Technology Office, U.S. Department of Energy, 1998, 167 p.

- Morea, M.F., "Advanced reservoir characterization in the Antelope shale to establish the viability of CO2 enhanced oil recovery in California's Monterey formation siliceous shales," annual technical progress report, Feb. 7, 1998-Feb. 6, 1999, Project DE-FC22-95BC14938, National Petroleum Technology Office, U.S. Department of Energy, 1999, 213 p.

The authors

Scott L. Montgomery is a Seattle petroleum consultant and author. He is lead author of the "E&P Notes" series in the AAPG Bulletin. He holds a BA degree in English from Knox College and an MS degree in geological sciences from Cornell University. E-mail: [email protected]

Michael Morea has wide experience in characterization and management of San Joaquin Valley reservoirs. With Chevron 19 years, his previous assignments include Alaska and California exploration, regional stratigraphic studies, designing steam and waterflood projects, property trades and acquisitions, and project management. He has a PhD degree from the University of California Riverside.

Pat Perri has more than 21 years with Chevron. He has worked as a reservoir engineer at Prudhoe Bay field and on miscible gas injection at Swanson River field in Alaska. He has extensive San Joaquin Valley experience at Elk Hills, Cymric, and Fruitvale fields and worked 2 years on Point Arguello field off California. For the last 5 years, Perri has worked on a Chevron team looking at using current and emerging technologies to improve recovery from siliceous shale reservoirs. He holds a BS degree in chemical engineering from University of Pittsburgh.

Mark Emanuele is a production engineering advisor for Chevron Petroleum Technology Co. in Houston, where he is involved in technical support of well completion and stimulation activities for Chevron's upstream operations worldwide. His main interests are in hydraulic fracture design and hydraulic fracturing diagnostics. Emanuele has 18 years with Chevron in operations, facilities, and production engineering. He holds a BS degree in petroleum and natural gas engineering from Penn State University.