Three exploration methods model gas field in New York

FIELD MODELING-1

A decade of restructuring has significantly altered the nature of the oil and gas industry and its approach to exploration, particularly in the US. A fluctuating commodity price, loss of experience due to downsizing, and increasing competition for investment capital have made exploration decisions, when made, increasingly critical to ensuring a company's economic survival.

In spite of the changes in the industry, the two most fundamental issues in hydrocarbon exploration still remain location of a trap and the verification of hydrocarbons in the trap. Many methods have been proposed to address the first issue, and the second issue has been best addressed by the application of surface geochemical analysis. Only in the past decade or so have geochemical service providers been able to address this issue with greater confidence. They have developed more rigorous sampling, analytical, quality control, and computer techniques for evaluating the results of field studies.

Newly developed analytical methods result in significantly lower detection limits and allow hydrocarbons to be detected at concentrations ranging from low parts per billion to high parts per trillion levels. This methodology allows detection of C2-C7 hydrocarbons that were undetectable in the 1980s and C5 hydrocarbons that were not even known to exist in the natural environment.

In addition, a variety of statistical techniques have been developed to afford better compound and mixture identification, as well as comparison of complex mixtures. These techniques permit sophisticated modeling of geochemical data that was not possible before the 1990s.

The benefit of these geochemical tools, especially when added into a coherent exploration program, is that they are inexpensive (i.e., a fraction of the cost of commercially available 2D and 3D seismic) and are accessible to even to the smallest independent company.

These data may be applied in either extremely small site-specific packages or on regional or basinal studies. Moreover, they can help answer the basic questions concerning the presence of petroleum and the existence of a trap. When properly used, they can enable virtually any size operator to enhance and support his exploration and development decision-making by a scientifically valid process. This results in a valid and inexpensive exploration model that can be sized for a client's needs.

Project parameters

Direct Geochemical Surveys and Pyron Consulting, under the auspices of the New York State Energy Research & Development Authority (NYSERDA), completed a surface geochemical survey demonstration project in selected areas of Tioga County, NY, during the spring and summer of 1998.

Samples from free soil gas samplers, known as VaporTec (trademark) passive collectors, as well as discrete soil samples were collected for analysis by two different and complementary methods: gas chromatography and UV fluorescence.

The purpose of this article, the first of two parts, is a discussion of the theoretical methods used in the NYSERDA study. The second article will contain a discussion of the application of this theory to real world exploration and development problems of the type independent operators may face.

The NYSERDA study samples that were collected in two areas of New York, a geologic (geochemical) model area and a prospect area. The samples were processed in a manner that would allow both rigorous processing and analysis. This assured high quality, representative data. Several steps that were taken to assure the quality of the data reported from the lab included:

- Log-in procedure

- Sample holding and storage

- Instrument calibration, both initial and continuing

- Surrogates

- Duplicates

- Blanks

These procedures provide assurance that the samples were handled and analyzed in reproducible and defensible ways and that the interpretations were not related to variations in analysis but to variations present in the soil or soil vapor in the field.

Analytical theory

Free soil gases are those that are actively migrating from subsurface sources and are trapped in the process. Absolute concentrations of free soil gases are generally lower than in soils.

Sampling of soils has the obvious advantage of simplicity and speed. It requires only a single trip to the field and can be accomplished with the simplest tools. The primary disadvantages are the variability of soil and the processes that affect the concentration and composition of hydrocarbons.

These variables can adversely affect the interpretation of data, particularly the quantitative analysis. Detailed soil descriptions should be made during field collection to help mitigate this potential problem. This methodology was used during the NYSERDA project.

Surface methods

Gas chromatography was run on all of the soil samples and on all of the passive soil gas samplers received from the field.

Two types of chemical analysis were run: thermal desorption-gas chromatography and UV fluorescence.

Gas chromatography operates on volatile or semi-volatile compounds in the vapor phase. To get the hydrocarbons into the vapor phase, it was necessary to heat the soil sample or the VaporTec sampler in a proprietary device to a temperature that will cause desorption of the hydrocarbons from the solid phase into the vapor phase, but not cause pyrolysis.

An aliquot of the desorbed hydrocarbons is then injected directly onto the chromatographic column for analysis on a HP 5890 gas chromatograph. An example of a chromatogram is provided in Fig. 1.

Prior to running the analysis, the gas chromatograph is calibrated to identify and quantify the compounds analyzed. Direct Geochemical selected a range of hydrocarbons from methane to hexane and performed a multipoint calibration. Following calibration, a system blank was run to assure that there was no carry-over and that the system was clean. Then, each sample was run in turn.

The raw data were transferred to a database for interpretation. This database provides the absolute concentration of each identified hydrocarbon compound in the aliquot of headspace analyzed, with a lower limit of detection of 5-10 parts per billion by volume (ppbv).

The analog output is the comparative chromatogram. A random comparative chromatogram (Fig. 2) is a powerful visual tool for examining complex data.

UV fluorescence methods

UV fluorescence analysis was performed on all of the soil samples. Each sample was carefully sieved for the silt and clay fraction to minus 60 mesh and then subjected to intense solvent extraction using a proprietary solvent.

The extraction incorporated a proprietary process of temperature control and agitation, followed by gravity separation of the solvent from the soil. An aliquot of the solvent was then placed in the beam of UV light in a Perkin-Elmer MPF-44 Fluorescence Spectrophotometer.

As with the gas chromatography, the instrument is first calibrated and then a blank is run to assure that there is no carry-over.

The acquired data were tabulated across a scan range of 250-500 nanometers (nm). Emission and excitation are scanned synchronously.

The resulting data are expressed in two formats. The first is digital and shows the fluorescence intensity at 5 specific wavelengths. In addition, a fluorescence spectrum can be prepared showing the continuous variation in fluorescence intensity with wavelength (Fig. 3). The results from the soil analysis were placed into a database for processing and interpretation.

Sampler analysis

Instantaneous sampling of free soil gas often results in the reporting of concentrations of methane through propane and little else.

Because samples often contain such low concentrations of indicator compounds, they require sampling at depths of 5-20 ft. Passive gas sampling affords improved reporting because it allows the concentration of hydrocarbon gases on a non-polar sorbent (e.g., activated carbon) from a more easily achievable (and shallower) depth.

The passive sampler employed in this project is the VaporTec sampler manufactured by Direct Geochemical. Samplers are placed into shallow (6 in.) core holes in the soil, buried, and left to trap and concentrate hydrocarbons for 2-3 weeks. They are then retrieved, sealed, and returned to the laboratory for analysis.

The primary advantage of the VaporTec sampler is that the trapping matrix of all samples is identical, and therefore, there is no variation in concentration due to sampling or sampler. In areas with highly variable soils, especially tending toward granular types with little organic carbon, VaporTec samplers assure a high quality, uniform gas sample.

Data interpretation

After the samples for the NYSERDA project were analyzed by the methods discussed above, the data were qualified and interpreted.

The basic interpretation approach involved the assumption that an existing, relatively well defined and characterized producing field or accumulation, if properly sampled and interpreted, could be used to develop a geochemical model or analog. Therefore, it was necessary to be able to "map" the extent of the known accumulation or productive zone in order to validate the model.

The interpretation of the data involved two independent evaluations, followed by an integration of geochemistry and geology.

The first, and most traditional, approach was to evaluate and map the absolute concentration of individual and groups of hydrocarbon species (or classes in UV fluorescence) identified in the survey.

The second approach is to evaluate the compositional variation. Compositional interpretation largely discounts the absolute concentration of hydrocarbon species and concentrates on their relative abundance.

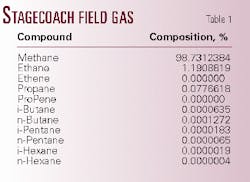

To aid the analysis, a field operator provided a representative sample of gas from the model area field (Table 1). The results from the soil, VaporTec, and representative natural gas analyses were entered into a database for processing and interpretation using a sophisticated statistical procedure.

Historically, the primary interpretative approach that is used in projects of this type is to map variations in concentration of individual or groups of hydrocarbons. There is almost always a strong variation in concentrations across a survey area. It is vital to appreciate how that variation relates to the presence of a subsurface hydrocarbon accumulation. Ideally, deep soil samples are used for quantitative interpretation, minimizing surface effects.

Due to a general lack of soil profile, shallow samples were used here. The proprietary thermal desorption process operated by Direct Geochemical, however, overcomes much of this disadvantage. The initial analysis of the model area by this approach was not successful, and led us to compositional analysis.

Compositional analysis takes into account the presence, the absence, and the relative abundance of hydrocarbon species. It is possible to apply a variety of multivariate analytical techniques to evaluate the mixture of species, particularly in relation to mixtures that are representative of known geological conditions.

While not essential, whenever it is possible, compositional analysis develops a chemical model or analog from existing production or at least a documented accumulation.

The ideal chemical model incorporates geologic information (presence and termination of reservoir conditions), lithology (log analysis), reservoir fluid analysis, well control, structural analysis, and surface geochemical information. The objective is to develop a chemical model that allows the differentiation of potentially productive from demonstrably nonproductive or noncommercial reservoirs.

Information on the boundaries of an accumulation, the geologic conditions that create them, and the chemical features in the data that are most diagnostic of that condition enable development of such a model.

Unlike most gas analyses for heating value purposes, when exploration is involved, it is vital to extend the range of analysis up to at least the C6 level. In doing so, we have observed detectable concentrations of C3-C5 hydrocarbons, with a trace of C6 in many samples. The presence of heavier hydrocarbons gives direct evidence of the presence of thermogenic subsurface accumulations.

Knowledge of background conditions is critical to this type of multivariate analysis. Background conditions are ordinarily quite variable, both in concentration and composition, resulting from a wide variety of influences and sources in the environment, including vegetative organics. Potentially productive conditions are more uniform in composition, reflecting a significant source of relatively uniform hydrocarbon character that compositionally, if not quantitatively, overwhelms the background.

The data set used to conduct compositional analysis is often very complex; involving 8-20 individually identified compounds. Conventional graphical methods can only display 2-3 variables at a time. And, traditional statistical methods cannot easily encompass such complex data and present it in an understandable format. Bi-variate analysis of data requires a large number of iterations and may yet be unable to explain the relationships in which 3-5 components are necessary.

Multivariate analysis processes a large number of variables at the same time, and can differentiate those variables that are related to known conditions and those that are not. The nature of these variables can be compared to the chemical features of known conditions (e.g., composition of natural gas). The technique can then be used to classify samples that are "unknown" as to their similarity to known conditions. The final classification was conducted using discriminant analysis.

To effect discriminant analysis, samples taken in the vicinity of either producing or dry wells (the known geologic conditions) were used to characterize the surface chemical features that best characterize production and are different from background (dry wells).

All unknown samples are then compared to the matrix developed by the known samples and the residual probability calculated. The residual probability is plotted on the map as a "gas probability" and contoured.

In Fig. 2, our comparative chromatograph is an example of the discriminant analysis used in our project. Sample 9804 (in red) was done for a sample collected in the vicinity of a producing gas well. It was judged to have a chromatographic response representative of a 99% gas probability potential. Sample 9883 (in blue) was collected in an area with little natural gas potential (i.e., less than or equal to 11%).

The peaks seen in the chromatograph for sample 9804, especially those seen at chart number 250 units and higher, were deemed diagnostic of the natural gas found in the reservoir. By establishing this "constant," analysis of samples collected from other non-developed areas could proceed; this was useful in projecting gas probability potential with some confidence to these areas.

In addition, the UV fluorescence data from soils was also evaluated using discriminant analysis. Because the fluorescence responds largely to aromatic hydrocarbons, and the content of some gas is largely devoid of aromatics, it was not expected that the UV fluorescence would be a direct indicator of gas accumulation, as the light hydrocarbon analysis is. In some instances, particularly in heavily laden condensate gases or in petroleum dominant systems, UV fluorescence can be used as a tool to indicate "gas probability."

Conclusions

Direct Geochemical Services has developed an exploration and production surface geochemical methodology that has been successfully applied to a "real world" problem in New York. This methodology is easily accessible to all size companies and is cost competitive.

This article has discussed the theory that supports the methodology. Significant in this discussion, and in the NYSERDA demonstration project, is the role that this low-cost geochemical method has played in the development of a confirmatory exploration model that we have identified as Integrated Exploration Technology (IET).

Acknowledgments

Direct Geochemical Services and Pyron Consulting thank NYSERDA and Dr. John Martin, the project manager, for our study. We also thank the many geologists and other professionals who reviewed our final report and made commentary on our public presentations on this topic.

The authors

Jim Viellenave is a principal geochemist at Direct Geochemical Services in Golden, Colo. He has been involved in surface geochemical exploration for mineral, geothermal, and petroleum resources since 1978. Before that he was with NERI and Earth Sciences Inc. He holds degrees in geography from the University of California.E-mail:[email protected]

John V. Fontana is a principal geochemist at Direct Geochemical Services. He has been involved in surface geochemical exploration for mineral, geothermal, and petroleum resources since 1981. Previously he was with the geochemical exploration division of Analex Corp. He holds degrees in geology, physics, and oceanography from Humboldt State University.

Art Pyron is sole proprietor of Pyron Consulting. He has 20 years of experience in oil and gas exploration and appraisals, minerals investigations, environmental studies, and site remediation. He has an MS degree in geology from the University of Texas at El Paso.