Expansions hike gas-liquids production capacity off West Africa

Expansion of CMS Oil & Gas Co.'s operated offshore Alba field facilities, off Equatorial Guinea, will increase the amount of condensate and gas liquids that can be exported from an existing gas-processing plant and a methanol plant, under construction, on Bioko Island.

CMS Oil & Gas Co., Houston, is a subsidiary of CMS Energy Corp., Dearborn, Mich.

Production capacity

Since production began in 1991, natural gas from the Alba field has been flared to recover the high concentration of liquids contained in the gas. CSM says production currently averages 90 MMscfd from which the onshore gas plant recovers 6,700 b/d of condensate and 1,700 b/d of LPG.

The expanded offshore facilities increase the field's producing capacity to 250 MMcfd of gas, increasing associated liquid production by 10,000 b/d upon completion of the methanol plant. CMS says of this 250 MMcfd produced, 130 MMcfd will go to the methanol plant, 20 MMcfd will be used in onshore operations, with 100 MMcfd being reinjected offshore.

CMS estimates the Alba field contains more than 1 tcf of proven gas reserves.

The $400 million, onshore methanol plant, under construction, has a design capacity of 2,500 tonne/day. CMS expects the plant to be completed in the second quarter of 2001.

Plant owner is Atlantic Methanol Production Co. (AMPCO), a joint venture of CMS (45%), Samedan Oil Co. (45%), and the government of Equatorial Guinea (10%).

Offshore expansion

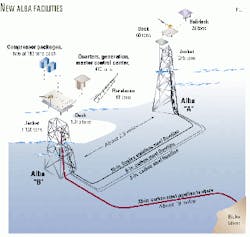

Global Offshore International Ltd., a subsidiary of Global Industries Ltd., Houston, completed the expansion program in April 2000. Global says it installed, in 250 ft of water, the Alba A tripod well platform, Alba B four-pile compression-quarters platform, a 10-in. duplex stainless-steel infield flowline, bundled 8-in. and 2-in. carbon-steel flowlines, and a 19 mile, 20-in. pipeline to Bioko Island. (Fig. 1)

The 10-in. duplex stainless steel line was required because by the carbon dioxide in the wet gas.

Global was awarded the engineering and fabrication contract for the work in March 1999 and offshore construction began January 2000 with Global's pipelaying and derrick barges Cheyenne and Comanche.