Pore salt content influences oil displacement efficiency

Experiments have determined that salt contained in pores changes the displacement efficiency in a stratified heterogeneous formation.

The laboratory experiments investigated the hard salt in the pore space of oil-saturated samples from the Verkhnechonsky gas-condensate field in East Siberia (Russia). Displacement fluids consisted of freshwater and water with chemical additives.

Distinctive features of the terrigenous formations in the Verkhnechonsky field include:

- Abnormally low original reservoir pressure, which is less than hydrostatic.

- Low reservoir temperature, 14-20° C. (57-60° F.).

- High saline formation water, about 400 g/l.

- Salt sections in the producing formations. Water-soluble salt, occupies 20-30% and in some cases 70-80% of pore volume (OGJ, July 19, 1999, p. 53).

Experimental procedure

The experiments were carried out using filled linear models as well as original samples from the producing formations. The oil model used an oil and kerosene mixture with a 4.5-5.5 mPa-sec viscosity. To avoid dissolving the salt, the modeling did not include interstitial water.

Medium-ground quartz sand in combination with common salt in different proportions formed the porous media, which included impermeable boundary surfaces. A photocolorimetry determined the displaced oil volume.

The model provided a way to determine oil recovery with a primary water drive at constant pressure drop and the additional oil recovery following the injection of fluid slugs with various compositions. Flow and phase composition were measured at each pipe (interlayer) outlet.

Oil displacement efficiency (ODE) was estimated for different salt content following primary oil recover with a water drive (ODE'). Filtration parameter change was estimated by the mobility ratio (MR in m-sq m/mPa-sec) in the saline (MRS) and non-saline (MR0) interlayer prior to and following displacement with various slugs.

MR' is the mobilibity ratio in the primary displacement phase; MR'' is the mobility ratio after additional oil recovery from the flooded model.

Salt influence

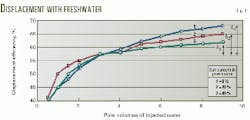

The experiments included 20 tests with non-saline porous media, 14 with 20 wt %. salinity media, and 6 with 50 wt % salinity media. Fig. 1 displays averaged results.

From Fig. 1, water displacement efficiency is about 57% after injection of about three pore volumes (PV). After nine pore volumes are injected, the efficiencies of additional washouts (di) decrease considerably, by 1.5 and 2.6 times for 20 and 50% salinity, compared to the non-saline tests.

This phenomenon might be accounted for by the increase in pore space surface with salt washout and the increase in residual oil saturation.

Increased pore space due to washout of salts compensated by external compression of the model, and irreversible deformation of pores with all other factors being equal, results in equal displacement efficiencies regardless of salt content. These are correspondingly 66.7 and 66.1 vol % with 0% and 50% salt content, according to another series of tests.

Capillary oil displacement

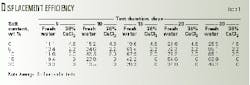

Several experiments included different salt content in the porous media and two different water compositions for oil displacement: freshwater and water containing 36% CaCl2 (Table 1).

In each set of tests, at least five parallel data readings were taken. Table 1 lists the averaged results. One can note that the greatest freshwater displacement efficiencies are with 5-10% salt content.

Polymer solution

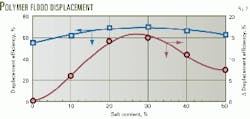

Six experiments, three series of tests, included a polymer solution. These tests used artificial samples with different salt content.

Fig. 2 compares the displacement efficiency of the polymer solution, and the difference of this parameter to a non-saline porous medium vs. the original salt content in the porous media.

One can note that the greatest efficiencies are in the interval where the salt content is 20-30 wt %.

Additional oil recovery

In the freshwater drive process, the filtration characteristics of the formation will vary depending on reservoir salinity. Consequently, natural permeable heterogeneity will be complicated by the man-made heterogeneity created by waterflooding.

This might decrease oil recovery, depending on the condition of the unrecovered oil in the flooded zone and the sweep efficiency.

Eight series of laboratory experiments, a total of 39 experiments, determined the effect of various chemicals for improving oil recovery from flooded stratified-heterogeneous saline filled porous media.

Table 2 lists the averaged results for seven different chemical compositions.

Water mobility

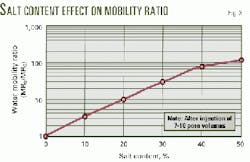

Fig 3 shows the results of 24 experiments on the dependence of water mobility on salt content. One can note that water mobility increases significantly as salt content increases.

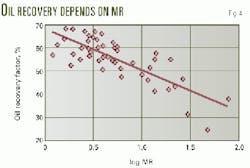

Based on 49 experiments, Fig. 4 shows the dependence of oil recovery in stratified-heterogeneous formations to salt content in the pores. The figure illustrates that oil recovery factors decrease as mobility ratio increases.

For the heterogeneous formations investigated, oil recovery factor is 68.2% at an mobility ratio of 1 and decreases to 50.6% with a mobility ratio of 10.

The authors-

Rasim N. Diyashev is deputy-director of geology and development of oil and gas reservoirs for TatNIPIneft Institute, Tatneft JSC, Bugulma, Russia. He specializes in the design and development of oil fields, well tests, and enhanced and thermal recovery of crude and bitumen.

Diyashev holds degrees as a technical-geophysicist from the Exploration Geology Technical School, Ufa, reservoir engineering from the Petroleum Institute, Ufa, and candidate and doctor of technical sciences from the Gubkin Institute of Oil & Gas Industry and the All-Union Petroleum Research Institute, Moscow. He is a member of SPE, AAPG, EAGE, and the Russian Academy of Natural Sciences (RANS).

Ivan F. Glumov works at the TatNIPIneft Institute, Tatneft JSC, Bugulma, Tatarstan, Russia. His area of interests is enhanced oil recovery, including application of unconventional approaches. Glumov graduated from Tomsk State University with a specialty in physical chemistry and has a candidate of technical sciences from the Petroleum and Gas Institute, Moscow.

Enver S. Ziganshin is the general director and main engineer for Rusia Petroleum Co., Irkutsk, Russia. He previously worked in drilling and as an engineer-technologist for exploration and production of oil and gas. Ziganshin is a graduate of the Buguruslanski Oil Technical School and the Kuibyshev Polytechnical Institute, specializing in oil and gas well drilling.

Vladimir A. Kazakov is vice-director and director general for Rusia Petroleum Co. Irkutsk, Russia. He previously was involved in drilling operations in West Siberia. Kazakov has degrees in production engineering from the Petroleum Technical School, and in mechanical engineering from Tomsk Polytechnical Institute.

Vladimir D. Kochetkov works at the TatNIPIneft Institute, Tatneft JSC, Bugulma, Tatarstan, Russia. He works on laboratory and field tests, and the introduction of new enhanced oil recovery methods, well stimulation, and water inflow isolation technology. Kochetkov graduated from Moscow Institute of Petrochemical & Gas Industry and the Moscow Gubkin Institute of Oil & Gas Industry.