Equipment/Software/Literature

Winch monitor

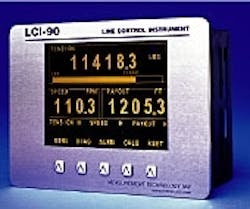

The LCI series winch monitor is designed for marine environments. Displaying sensor and transducer input information on line tension, line payout, and speed, the monitor has been specifically engineered for uses such as mooring line monitoring on semisubmersible drilling rigs and construction barges and winch monitoring and control on oceanographic, seismic, and anchor handling workboats.

One feature of the LCI is its electroluminescent display. Housed in a stainless steel, NEMA 4X/IP66 front panel that may be installed on deck or console mounted in a control room, the display is easily readable in bright sunlight or total darkness, and may be viewed from an angle of 160°. The flush, front panel push buttons access all programming, diagnostic, and control functions for the device.

Completely self-contained, the standard monitor is available with four analog input channels, a counterinput, six programmable alarm relays, sensor excitation voltage, and is powered by 18-36 v dc. Options include analog and serial outputs for remote communication, four input/output channels, a number of analog input and excitation alternatives, and 85-240 v ac power.

Source: Allison Group, Marine Instrumentation, Box 271912, Houston, TX 77277.

General purpose level transmitter

A new noncontact liquid level transmitter combines ultrasonic transducer technology with control electronics. Designed as a low-cost, general purpose level transmitter, the MSP422 offers reliability and performance, the company says.

The new instrument is housed in a nylon casing sealed to IP66/67, with inert PDVF wet sides for compatibility with most liquids. In chemical and other processing operations, it is suited for most types of process and storage tanks.

The unit has a built-in false target recognition and rejection feature. It can be programmed to ignore the effects of stirrers, paddles, or other intrusions, avoiding false alarms and improving the reliability and credibility of the reading, the company points out.

This self-contained, noncontact, ultrasonic transmitter is quick and easy to install, requiring only a single mounting bracket above the liquid level surface. Set-up and commissioning are completed in a few minutes using the simple three-key pad and LCD positioned inside the lid.

The industry standard 4-20 ma output signal can be used to drive a display, alarm or closed-loop controller, or linked into a PLC, SCADA, or computerized control system.

Source: Solartron Mobrey Ltd., 158 Edinburgh Ave., Slough, SL1 4UE, UK.

Radiators, oil coolers for oil field areas

New custom made radiators and oil coolers comply with safety requirements for oil field operations.

In one instance, for example, units made for Progenitive Services Ltd., Aberdeen, could only reach a specified maximum temperature. This was crucial on soundproofed pumps operated by Progenitive. The engines were fitted with a flameproof protection system that allowed the diesel pumps to maintain operating temperatures below the maximum specified to function within zone two hazardous areas.

The company configured a radiator system featuring integral coolers for the hydraulic and lubricating oil systems to satisfy the maximum heat dissipation levels specified by Progenitive. This high performance unit measures 2 m high by 1.8 m wide and is less than 0.7 m deep.

Source: Becool Radiators, Gallay Ltd., Paterson Rd., Wellingborough NN8 4BZ, UK.

Flow control additive

New DeepWater Flo-Stop (DWFS) 5000 is a single liquid additive used to control hazardous shallow water flow zones while cementing in deep water.

The additive can be used with the cement already on the rig.

The additive helps improve the deepwater cementing success rate by adjusting slurry performance properties to prevent saltwater or gas influx, the company notes.

Cement gellation or "transition time" for conventional slurries in deep water can be as lengthy as 3 hr, often allowing the entry of fluid or gas. Under the same cool temperature deepwater conditions, DWFS 5000 transitions in less than 30 min, the firm says. In addition to decreasing slurry transition times, DWFS 5000 helps maintain the hydrostatic pressure on the formation, which also helps decrease the chance of fluid or gas influx.

When combined with the proprietary ZoneSeal Isolation Process, DWFS 5000 provides a compressible cement that will maintain pressure on the formation during the transition time. These low-density, compressible systems also assist with drilling fluid displacement and generate the compressive strength necessary to help assure maximum zonal isolation and long-term reservoir access.

Source: Halliburton Energy Services, 3600 Lincoln Plaza, 500 N. Akard St., Dallas, TX 75201-3391.