Horizontal gravel packing optimizes well productivity

During redevelopment of the Uracoa field in Southern Monagas, horizontal gravel-packed completions proved better at restoring and maintaining well productivity than other completion techniques.

A comparison of the different completion practices indicated that:

- Gravel-packed screens in horizontal wells maintained production longer compared to stand-alone slotted liners.

- Horizontal completions provided higher production rates than vertical or directional completions, including frac-packs.

- Frac-packed wells performed better than conventional non-fraced wells, but not as well as horizontal wells. Frac-packed wells maintained production longer than stand-alone slotted liners in horizontal wells.

- Horizontal well technology revitalized the Uracoa field, improving production from an average of 243 bo/d/well from nine wells to 42,000 bo/d from the field.

- In only 61/2 years, horizontal wells were instrumental in producing 43% of the estimated 114 million bbl of oil that may be recovered from the field.

Uracoa field

The Uracoa field is in the south-central portion of the state of Monagas, about 10 km southeast of Temblador, 40 km southwest of Tucupita, and 125 km southeast of Maturin.

The topography of 1/2 the area is relatively flat and gently inclines to the southeast towards the Uracoa delta. Minor ground undulation produces low areas that become swampy during the rainy season.

Vegetation is sparse in the plains but dense in the swamps and along the riverbanks.

The Uracoa field lies on the southern flank of the Maturin basin. The field is part of a structural trend that runs along the southern portion of Monagas in a northeast-southwest direction.

The geological structure is a homocline gently dipping 4-6° to the north-northeast. This homocline strikes N85°E and is cut by the major Tabasca east-west fault that controls reservoir closure to the south.

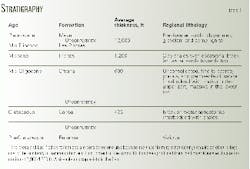

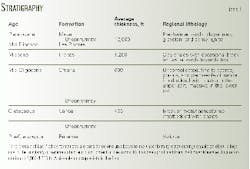

Secondary transverse faulting provides the necessary lateral closure for oil accumulations and divides the field into five reservoir blocks (Fig. 1). Table 1 summarizes the stratigraphic section.

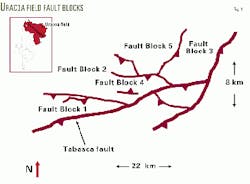

Secondary faulting divides the Oficina sands horizontally into five reservoir sections (Fig. 2). A strong natural water drive provides the producing mechanism. A large gas cap covers most of the field, with the gas-oil contact being fairly level at -4,150 ft below sea level in all fault blocks.

Oil specific gravity decreases with depth, ranging between 11.7 and 16.2° API and averaging 15° API. Formation permeability averages 2-5 Darcies and can be as great as 10 Darcies. Porosity averages 24%, and connate water saturation is 23.9%.

Table 2 lists general reservoir characteristics.

Benton Vinccler CA's new reservoir study includes new maps generated from 3D seismic. The study estimates original oil in place of 515.8 million stock tank bbl (stb). Conventional cores from wells UM-91 and UM-84 indicate that the reservoir has a 27.8-29.1% average porosity, 2.7-Darcy permeability, and a 65-70% hydrocarbon saturation.

With a 1.09 reservoir bbl/stb formation volume factor and a 379,997 acre-ft net reservoir volume, the current recovery amounts to 10.3% of the original oil in place. About 61 million stb remain to be recovered, assuming an ultimate oil recovery of 22.09%.

Benton is continuing to evaluate new data and these numbers may change in the future.

Production history

The field was discovered in May 1937, when Standard Oil of Venezuela and Pantepec drilled Well Tabasca-1 (UP-1), completed in the Oficina formation with an initial production rate of 346 b/d of 14.7° API heavy oil. The discovery was made based on early seismic surveys that delineated the main Tabasca fault.

A second well, UM-1, was completed in 1937 before drilling operations were suspended in Uracoa because of the low 11.7° API oil gravity.

Drilling resumed in 1953 with Wells UC-1 and UC-2, followed by another period of inactivity until 1956, when five producers and three dry holes were drilled. Another producer, UM-6, was completed in late 1957, but further development was again suspended because of the low oil gravity.

The field then produced during three periods (August 1970 through July 1971, March 1974 through December 1975, and July 1977 through May 1980) before production ceased because of market considerations. Production resumed after Petróleos de Venezuela SA granted a service contract to Benton Vinccler in 1992. Benton reactivated several existing wells in March 1993 and started drilling new wells in October 1993.

As of August 1999 in the Uracoa field, Benton had drilled 119 wells-25 vertical, 37 directional, and 57 horizontal wells. These include five water disposal and three gas injection wells.

Cumulative Uracoa production as of August 1999 was 52.9 million stb of oil and 44.2 bcf of gas.

Benton Oil & Gas Co. approached Baker Oil Tools in September 1994 because of production problems in numerous wells with slotted liners in the open hole. Initial well production rates were 4,000-5,000 bo/d from five horizontal wells with slotted liners, but production declined after 11-12 months, along with increased sand production and water cut.

Because production is from unconsolidated formations, Baker Oil Tools recommended horizontal openhole gravel-packed completions. To date, more than 60 of these completions have been successfully installed since the fall of 1994 in both the Uracoa and Tucapita fields.

Horizontal wells have allowed Benton to increase production to a peak of 42,000 bo/d in October 1997 from an initial 243 bo/d from nine reactivated wells at the start of its operations in March 1993.

The production rates from openhole gravel-packed horizontal wells have consistently been better that rates from vertical and directional wells.

Horizontal gravel packs

In fall 1994, Benton began horizontal gravel packing wells to eliminate the problems associated with stand-alone slotted liners. Slotted-liner completions initially provided the desired production rates.

As previously mentioned, however, these completions were short lived. Failures can be attributed to several possible mechanisms, including failures due to screen plugging, erosion, and corrosion.

One attempt to prolong the screen life involves gravel packing to control sand influx into the open hole. In Uracoa, several different screen types were run including slim prepacked screens and wire-wrapped screens.

Gravel packing with low-viscosity fluids is the basis of formation sand control in less consolidated formations. The entire gravel pack functions as a filter and the screen is a gravel retention device.

Experience shows that very seldom do wellbores collapse completely around stand-alone screens, thereby leaving an open annulus to transport plugging material to the screen. Many well failures, including those in Uracoa, can be attributed to screen plugging and consequently productivity declines or cessation of production.

Gravel packs, on the other hand, provide support to the borehole and fill the annulus with gravel sized to retain formation sand so that progressive screen plugging is avoided.

A clean, stable, undamaged well is needed prior to running a screen and performing a gravel pack. A dirty wellbore contaminated with gravel will lead to a poor completion.

In a dirty-well scenario, stand-alone screen completions initially may produce at higher rates than gravel packs, but eventually they will plug. Gravel packs will produce at lower rates but sustain production longer.

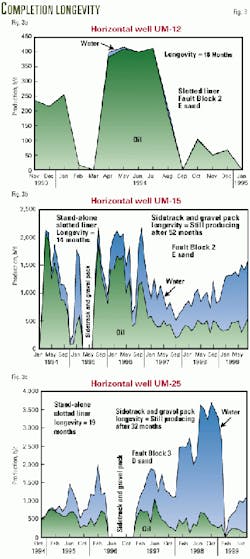

As illustrated by the experience in the Uracoa field, gravel packing both vertical and horizontal wells leads to sustained productivity. Fig. 3 shows the total fluid production of Wells UM-12, UM-15, and UM-25. These wells originally employed stand-alone slotted liners.

Well UM-12 (Fig. 3a) failed after producing for only 15 months. Wells UM-15 and UM-25 (Figs. 3b and 3c), which were sidetracked and recompleted as horizontal gravel packs after the stand-alone slotted liners failed, lasted 14 and 19 months, respectively, before failure of the stand-alone screen.

Figs. 3a and 3b also illustrate the increased producing life of gravel-packed wells even with increased water production. Wells UM-15 and UM-25 are still producing after 52 and 32 months, respectively, since being recompleted with gravel-packs.

Well UM-25 (Fig. 3d) compares production from a stand-alone slotted liner and a sidetrack with a gravel pack.

Completion comparisons

In the Uracoa field, Benton used several completion techniques, thereby providing a unique opportunity to compare production from different completion types. Before Benton became operator, only conventional vertical wells had been drilled in the field. Benton began drilling directional and horizontal wells and initially included stand-alone slotted liners in five wells.

Because these completions had a short producing life, Benton began employing openhole horizontal gravel packs. The 61/8-in. open hole horizontal lateral lengths ranged from 870 to 1,770 ft and averaged 1,600 ft.

In summer 1996, Benton started frac-packing a few wells. Six directional wells were fraced.

The Uracoa field contains five different fault blocks with Oficina sand production characteristics varying between fault blocks. Therefore, the completion tehniques comparison was limited to wells in similar formations.

The wells for the comparison were primarily in Fault Blocks 2 and 3. These wells were completed in either the E or F sand. These two sands are similar in both fault blocks and merge into one sand in some parts of the field, making differentiation between the sands difficult.

It was, however, impossible to compare wells that had all the same reservoir parameters and completion techniques. For illustration purposes, the wells are sufficiently similar to make general conclusions.

Fig. 4 compares the initial year of production by month of five directional gravel packed wells, five horizontal wells with stand-alone slotted liners, seven horizontal gravel-packed wells, and six directional frac-packed wells.

The figure only includes the first year of production because the stand-alone slotted liners failed soon after 1 year. Other figures extend the production out to longer time periods but are not included in this article because they show the same trend between directional and horizontal wells.

As expected, horizontal wells outperformed directional gravel packs and directional frac packs. Also, horizontal gravel packs outperformed the horizontal stand-alone slotted-liner completions.

Fig. 4a compares only oil production, but Fig. 4b compares total fluid production and illustrates the well capacity to produce high fluid volumes. Proximity of the wellbore to the oil-water contact and water cuts are not constant; therefore, total fluid production had to be considered for a valid comparison.

As Fig. 4 shows, the openhole gravel-packed wells produced 300-1,000 bbl more total fluid than the frac-packed wells and 700-1,200 bbl more than directional wells.

Frac packs are intended to produce an hydraulic fracture beyond the damaged zone of the wellbore that provides a more efficient path for fluid inflow.

In high-permeability formations, the fracture length does not have to be very long to obtain a maximum producing rate.

Reservoir characteristics are of equal importance for selecting the proper completion technique. The Uracoa field's productive Oficina sands are ideal candidates for horizontal completions. The E and F sands are thick, 50-200 ft, homogeneous sands that lend themselves well to horizontal completions.

Longer horizontal sections, in this case, provide more inflow surface area at lower drawdowns, thus resulting in the most efficient completion.

Nodal analysis on Uracoa wells indicate that frac packs would be better than horizontal openhole gravel packs only if the overall sand thickness exceeded 150 ft. Directional wells, on the other hand, would be the best completion choice in other parts of the field where the sands are thinner and multiple pays exist.

Acknowledgments

The authors thank the management of Baker Oil Tools and Benton Vinccler CA for permission to publish this article. We are also grateful to the Benton Vinccler personnel who helped provide the data.

References

- Campo Uracoa-Informe Del Campo Uracoa, Report, Benton Vinccler, Maturin, Venezuela, 1997.

- Horizontal Completion's Best Practices, Technical Report No. 1086, Baker Oil Tools, Sand Control Systems, Dec. 3, 1996.

- Mathis, S.P., and Saucier, R.J., "Water-Fracturing vs. Frac-Packing: Well Performance Comparison and Completion Type Selection Criteria," Paper No. SPE 38593, SPE Annual Technical Conference and Exhibition, San Antonio, Oct. 5-8, 1997.

- Mink, R.D., Geological Subsurface Review of the Uracoa Field, Report No. 3323-228-, Creole Petroleum Corp., Eastern Division Geological Operations Group, Quiriquire, Monagas, Venezuela, Apr. 9, 1959.

- Uracoa Field General Information-1, Report, Benton Vinccler, Maturin, Venezuela. Oct. 1, 1959.

The authors

Simon P. Benavides is a senior applications engineer for Baker Oil Tool's sand control systems, Houston. He is primarily responsible for formation evaluation and reservoir technology in support of sand-control design. He previously was a reservoir engineer for Quintana Petroleum and a log analyst for Schlumberger and Numar Corp.

Benavides holds a BA in mathematics from Lamar University and a BS in mechanical engineering from the University of Houston.

John Paul McKee is the production manager for Benton Vinccler CA, Maturin, Venezuela. He has been with Benton Vinccler for 4 years. Previously, he worked for Unocal Corp. in production, drilling, and reservoir engineering. McKee holds a BS in mechanical engineering from Mississippi State University.