Chinese refinery uses new catalyst to meet olefin regulations

In a 57-day commercial run at its Luoyang, China, refinery, Sinopec demonstrated a new fluid-catalytic cracking unit (FCCU) catalyst that reduced the olefins content of its refinery's gasoline to meet stricter transportation regulations.

By adjusting some operating parameters and using this new catalyst, called GOR (Gasoline Olefin Reduction), Sinopec reduced the olefin content in its gasoline product by 14 vol % while maintaining the constant RON.

The FCCU in the Sinopec Luoyang refinery is a side-by-side, full riser, single-staged regeneration unit. Its feedstock is atmospheric residue. Fig. 1 shows a photo of the unit.

The original FCCU, built in 1978, had a design capacity of 2 million tonnes/year (tpy) of vacuum distillate oil. In 1985, Sinopec revamped it to process atmospheric residue at a rate of 1.4 million tpy.

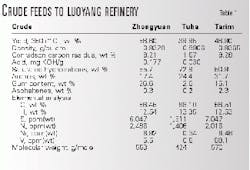

The unit uses a combined feed of Zhongyuan, Tuha, and Tarim crude oils. Table 1 lists each feedstock's properties.

The Conradson carbon residue of the blended atmospheric residue is 6-7%. The salt content in the demineralized atmospheric residue is about 4 mg/l., and the vanadium content is 10-15 ppm(wt).

New gasoline specs

In response to the air pollution caused by the increasing numbers of automobiles in China, the government of China, via the Environment Protection Department & Technical Supervision Department, limited the olefin content of gasoline, beginning July 1, 2000, to 35 vol %.

Although olefins increase the octane number of fuels, their thermal instability makes them less resistant to gum formation. Sediment adhering to gum formation seriously affects the tail gas discharge of automobile.

Olefins are also highly volatile. Thus, their vapors contribute to the formation of ozone in the troposphere.

Despite the gap between China's new olefins standard and that of developed countries, most Chinese refineries have found it difficult to meet the standards by solely adjusting operating conditions.

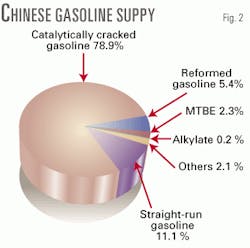

The average olefin content in Chinese refineries' gas oil is high. FCCU gas oil accounts for 80% of China's high-octane gasoline. MTBE, alkylate, isomerate, and reformed gasoline contribute a much smaller portion to high-octane gasoline. The pie chart in Fig. 2 shows the contribution of various gasoline types and additives to the Chinese market.

Catalyst specs

Without the new catalyst, the olefin content in Sinopec's Luoyang FCCU gasoline was usually more than 48 vol %. Sinopec found that it could not meet the government's 35 vol % olefins limit by merely adjusting the operating conditions.

Thus, the company developed its own olefins-reducing catalyst, which it will market to the refining industry in the near future. A commercial application of GOR in Sinopec's Luoyang complex showed that the new catalyst effectively reduced the olefin content in gasoline.

Sinopec had several performance goals for the new catalyst. It should:

- Enhance hydrogen transfer to saturate the olefin.

- Selectively crack olefins into LPG.

- Produce gasoline with a research octane number of at least 90 via alkane isomerization.

By increasing the content of rare earth metals and adopting special molecular mesh technology, Sinopec enhanced the catalyst's hydrogen transfer reaction. A ZSM-5 additive helps selectively crack C5-C7 olefins into C3s and C4s.

Finally, alkane isomerization raises the gasoline octane number to remedy the loss of the octane number caused by the saturated olefins.

Effects of changing operating conditions

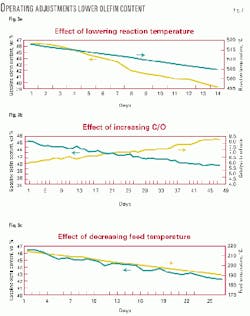

Sinopec carefully controlled three operating parameters during the commercial trial of GOR: reaction temperature, catalyst-to-oil ratio (C/O ratio), and feed temperature. These three parameters most affected the olefins content of the gasoline product.

- Reaction temperature. In the primary reaction, with the application of GOR, distillate oil first produced an alkane and an olefin. In the secondary reaction, olefins isomerization, hydrogen transfer, condensation, and coking occur.

Research in the lab and study in the commercial unit showed that lower reaction temperatures during hydrogen transfer are desirable, because they reduce the olefin content. Fig. 3a shows that when reactor temperature was decreased in the commercial unit from 518° C. to 500° C., the olefin content decreased from 46 wt % to 40 wt %.

- C/O ratio. Since the hydrogen transfer reaction only saturates the olefin, it will not deplete the alkane. Increasing the C/O ratio increased the total volume of the catalyst centers that contacted the feed, reducing the olefin content and increasing the alkanes and aromatics content.

When Sinopec increased the C/O ratios in the commercial trial, a notable reduction in the olefins content occurred. Fig. 3b shows that when the C/O ratio was increased by 2 units, the olefin content decreased by 4 wt %.

In some units, the amount of direct adjustment of the C/O ratio is limited. Adjusting secondary parameters can increase the C/O ratio, however. These include:

- Reducing the preheat temperature of the crude oil by at least 30° C.

- Increasing the catalyst-addition rate to the unit.

- Increasing the cooling duty of the catalyst cooler.

- Decreasing the regenerator-bed temperature.

Reducing the olefin content also improves the motor octane number (MON), because it increases the aromatics content.

- Feed temperature. Fig. 3c shows the relationship between changes of olefin and feed temperature with constant catalyst activity. When Sinopec decreased the feed temperature from 225° C. to 185° C., the FCCU gasoline olefin content decreased by 4 wt %.

Lower olefins, steady RON

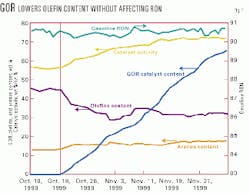

Sinopec began to add GOR to the system on Oct. 18, 1999, via an automatic feeder. Fig. 4 shows that as new catalyst volume increased from 0 wt % to 66 wt % during steady feed and operating conditions, the olefins content decreased, the aromatics content slightly increased, and the RON remained steady.

As the volume of the new catalyst increased from 56% to 72%, the olefin content decreased from 45.6 vol % to 31.5 vol %, while the octane number remained unchanged. The activity of the catalyst, which was sampled periodically during the run, was measured in a microreactor.

GOR not only reduces the olefin content, but also maintains a good product distribution. The graph in Fig. 5 shows that LPG, gasoline, and diesel production were steady during the commercial tests.

Fig. 6 shows that the propylene content in the LPG byproduct increased when GOR was used in the FCCU. It seems likely that GOR selectively cracked the olefins into the LPG.

The authors

Xiaodong Ye is the FCC manager and a senior engineer at Sinopec's Luoyang petrochemical complex. He currently develops optimization software packages and computer simulation for the refinery. Ye has more than 12 years of experience in FCCU operation and processing design. He holds a BS in chemistry from Lanzhou University, Lanzhou, Gansu, China.

Weizhou Jiao is an engineer at Sinopec's Luoyang petrochemical complex. He has more than 7 years of experience in operating, design, and development of FCCU technology. Jiao holds a BS in engineering from Tianjin University, Tianjin, and an MS in petroleum engineering from the Petroleum University, Beijing.

Yaoyu Liu is an engineer at Sinopec's Luoyang petrochemical complex. He has 9 years of experience in operation and design of refining technology. He holds a BS in petroleum engineering from the University of Petroleum, Dongying, Shandong, China.

Meng Xu works in the Foreign Affairs Department of Sinopec's Luoyang petrochemical complex. Previously, she worked in Sinopec's Research Institute, Luoyang. She holds a degree in chemical engineering at Northwest University, Xian, Shanxi, China.