Equipment/Software/Literature

New welded line pipe

A new welded line pipe features earthquake-resistant performance.

Called NK-HIPER, the firm says its new pipe excels in absorption properties for compression and bending deformation, which would result from ground movements because of liquefaction during earthquakes. The new pipe tests at 1.5 times higher resistance to such deformation compared with conventional pipe of the same specification, the firm says.

Pipe is made of high-strength, high-toughness steel plate. It complies with JIS, API, and other line pipe specifications. Because of the reduced carbon equivalent in the steel, the pipe offers good weldability and toughness, while improving quake-resistant properties. Because of the improved steel strength, it is also possible to make thinner-wall pipe.

Its resistance to bending deformation and water pressure facilitate safer installation in deep water, the firm notes.

Source: NKK, c/o Philip Taggart Co., 5177 Richmond Ave., Suite 750, Houston, TX 77056.

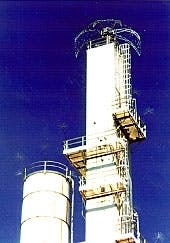

Protection against lightning strikes

The dissipation array system (DAS) lightning protection system is based on a natural phenomenon known as the "point discharge" principle or charge transfer. A sharp point in a strong electrostatic field will leak off electrons by ionizing the adjacent air molecules, providing the point's potential is raised 10,000 v above that of its surroundings. This principle is demonstrated by what is called natural dissipation. The ionization produced by trees, grass, towers, fences, and other structures can naturally dissipate as much as 90% of the total energy generated by a storm, thereby preventing the formation of lightning.

The DAS employs the point discharge principle by providing thousands of points with specific point separation that simultaneously produce ions over a large area, thus preventing the formation of a streamer, which is the precursor of a lightning strike.

This ionization process creates a flow of current from the point(s) into the surrounding air. Under storm conditions, this ionization current increases exponentially with the storm's electrostatic field, which can reach levels as high as 30,000 v/m of elevation above earth during a mature storm.

The charge induced on the site by the storm is removed from the protected area and transferred to the air molecules. These charged molecules then move away from the site.

Thus DAS helps prevent strikes by continually lowering the voltage differential between the ground and the charged cloud to well below the lightning potential, even in a worst-case storm. This differential has been measured at as much as 6,000%.

Source: Lightning Eliminators & Consultants Inc., 6687 Arapahoe Rd., Boulder, CO 80303.

New refrigerant leak detector

This new refrigerant leak detector-the Informant-uses microprocessor-controlled circuitry and a responsive, patented, heated diode sensor with a response time of 2/10 sec.The detector automatically locates refrigerants and detects the exact point of the leak.

Unlike units that require operators to determine what types of refrigerants they are looking for up front via a sensitivity adjustment switch, the Informant quickly responsds to all types of refrigerants, the firm says. Resetting or switching the unit to detect different refrigerant types is unnecessary.

Additionally, the instrument has the capability to automatically focus on and isolate a leak source even when high levels of background vapors or refrigerant are present. The unit features an audible indicator with a mute option, as well as three visual leak indicators-LEDs that light up in sequence to show an increasing concentration of refrigerant that can be seen from any position, and a flashing light at the tip of the probe that blinks when a leak is located to indicate changing gas concentrations. The lighted probe tip also prevents operators from ever having to take their eyes off their sampling location. These indicators are effective in direct sunlight and also when in the presence of significant background noise.

The unit's 20 in. probe, which can be wrapped around the instrument and used as a 3 in. probe, enables operators to find hard to reach leak sources. The probe end is tapered to a 0.2 in. diameter and is only about 1 in. long so operators can get in between coils and fittings and gain access to difficult leak sources. Additionally, an optional rubber boot is available with a cavity for a MagLite flashlight, which allows for one-handed inspections.

Source: Bacharach Inc., 625 AlphaDrive, Pittsburgh, PA 15238.