Canadian company builds largest ethylene and polyethylene complex

Nova Chemicals Corp., Calgary, is nearing completion of a $1.4-billion (US) expansion that will make its Joffre petrochemical site in central Alberta the largest ethylene and polyethylene complex in the world, according to the company.

Once the project's ethylene and polyethylene plants begin operating, Nova Chemicals will become North America's third-largest ethylene producer (7.8 billion lb/year capacity) and fifth-largest polyethylene producer (3.5 billion lb/year).

Joffre 2000, as the expansion is called, has been a massive 4-year undertaking. It required the design and construction of four facilities and their supporting infrastructure on an 890-acre site where four other Nova Chemicals' plants already operate (two ethylene, one polyethylene, and a hydrogen off-gas facility).

With the expansion, Nova Chemicals has created a largely self-sufficient petrochemical complex that produces most of its intermediate feedstocks and synergistically builds on a number of efficiencies.

Expansion scope

The largest new facility is a $750-million Ethylene 3 plant (E3), which will be the world's largest ethane cracker (Fig. 1). When E3 comes on stream in August, its annual rated production capacity of 2.81 billion lb of ethylene will complement the 3.4 billion lb from the Ethylene 1 (E1) and Ethylene 2 (E2) plants, which began operating in 1979 and 1984, respectively.

The nearby Polyethylene 2 plant (PE2) will be the world's largest solution polyethylene plant and the first commercial facility to use Nova Chemicals' Advanced Sclairtech, a catalyst and process technology that creates various grades of high-margin products.

The PE2 plant will begin commercial operation in early 2001 and will have an initial annual production capacity of 850 million lb of polyethylene. The existing 16-year-old Polyethylene 1 plant (PE1) produces up to 1.2 billion lb of linear low-density polyethylene.

A third new facility, completed last month, is Canada's largest privately owned cogeneration plant, a 416-Mw facility that produces electricity and steam for the entire Joffre petrochemical site and sells surplus electricity to Alberta's power grid.

The fourth facility is Canada's first linear alpha olefins (LAO) plant, scheduled for start-up in 2001. Amoco Canada Chemical Co. is building the plant on the Joffre site. This world-scale plant has a start-up annual production capacity of 250,000 tonnes, which is expandable to 375,000 tonnes.

The LAO plant leverages on the site's infrastructure. It will use ethylene feedstock from E3 to produce LAO, some of which will in turn supply Nova Chemicals' polyethylene plants (including the PE2 plant) and reduce imports of this feedstock from the Gulf Coast.

Infrastructure developments

Nova Chemicals is investing $310 million in infrastructure upgrades and participating in a $260 million cogeneration plant to accommodate a near-doubling of the site's overall petrochemical production capacity. These upgrades include new cooling systems, telecommunications equipment, water treatment, power distribution and fire fighting facilities, and expanded storage and handling facilities to feed Canada's largest private fleet of rail cars.

The biggest infrastructure investment is the cogeneration plant, which began commercial operations in June 2000. Nova Chemicals was project manager for the 416-Mw plant. Black & Veatch, Kansas City, performed the engineering and construction on a lump sum, turnkey basis. Nova Chemicals retains a 20% interest. Epcor and Atco Electric, Alberta electrical utility providers, each owns 40%. Atco is the plant operator.

The expanded Joffre site is expected to use 128 Mw of the plant's electricity. The remaining 288 Mw will be available for sale to meet Alberta's growing power demands. The plant will increase Alberta's overall electrical generation by 4%.

Natural gas powers the cogeneration plant, which gives Nova Chemicals an offset in greenhouse gas emissions associated with petrochemical production. Compared with coal-fired electricity generation, the gas-fired cogeneration facility has about 50% fewer emissions, along with an increase in energy efficiency of more than 50%, says Doug Ferris, the company's vice-president of engineering and projects.

The cogeneration plant consists of two Siemens-Westinghouse 501F combustion turbine generators, each with a heat-recovery boiler supplying steam to a single steam-turbine generator. The plant uses natural gas to simultaneously produce electrical energy and steam through the recovery of exhaust heat.

Technologies

The most noteworthy technologies in the expansion are the ethylene process, the polyethylene process, and advanced process controls.

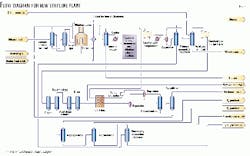

Although the basic chemical process of the E3 plant is similar to that of E1 and E2, it is more energy efficient and achieves a higher economy of scale. The E3 plant uses the latest in plate-fin heat exchangers and employs larger, more-efficient furnaces that require fewer turnarounds.

With more-integrated heat exchange systems, the company needs less energy to produce a pound of ethane than it used to. E2 requires 11,000 btu/lb, while E3 cuts that to 7,000 btu.

Fig. 2 is a simple flow diagram of the E3 plant.

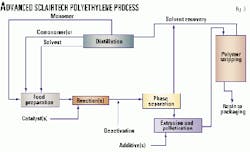

The biggest technological innovation at Joffre 2000 is the Advanced Sclairtech process (Fig. 3) that will drive the PE2 plant. Nova Chemicals acquired the predecessor of this technology in 1994 when it bought the polyethylene assets of Dupont Canada, which included its Sarnia, Ont., plant along the St. Clair River.

Nova Chemicals extensively modified the technology at both Sarnia and its Calgary research facilities, resulting in the latest development, Advanced Sclairtech. The company has tested the technology in a Sarnia developmental plant since 1996. Joffre's PE2 is the first commercial plant to apply the technology.

Advanced Sclairtech technology polymerizes ethylene and comonomers in a liquid organic solvent to produce polyethylene. At the heart of the new process is an improved catalyst and reactor system that provides better chemistry and better control of the molecular structure of the polymers produced.

"It has the flexibility to customize the properties that customers want, and they can process it more quickly and easily than today's polymers [technologies]. With this technology, you can make products with a broad range of densities," says PE2 manufacturing leader Tom Strifler.

Nova Chemicals' expansion project will use a DCS Honeywell system for its advanced process controls.

"Advanced process control is going to be the key in ensuring control of the reactor and of product characteristics so you can produce the same resins over and over again. The complexity of the reactor system requires that you understand all the kinetics," says Strifler.

Economies of scale

With these new facilities, Nova Chemicals' underlying drive is to be the industry's lowest-cost producer. The expansion places Nova Chemicals on a more equal footing with its Gulf Coast competitors who have lower transportation costs to export markets.

"If you're a high-cost producer in this industry, you get hit hard when prices are low. But if you're a low-cost producer, you can survive when prices are low and do very well when prices are high," says Ferris. "You can't do anything about the market, but you can do something about your cost structure."

Traditionally, the global competitiveness of Canadian petrochemical producers relied heavily on their access to plentiful supplies of low-priced Alberta ethane. The Alliance pipeline, scheduled to come into service in late 2000, is expected to transport up to 60,000 b/d of ethane out of Alberta.

In an effort to offset this situation, the Alberta government announced changes to its natural gas liquids royalty program. If these changes are adopted, they are expected to improve the incentives for natural gas liquids extraction in Alberta. In any event, Nova Chemicals has finalized new, more favorable medium-term, ethane-purchase agreements for a significant portion of the ethane used to produce ethylene at its existing Joffre facilities (E1 and E2) and all of its ethane requirements for E3.

To further lower its Joffre production costs, Nova Chemicals expanded to increase economies of scale. To make a new ethylene plant economically viable, it formed a joint venture in 1996 with nearby competitor Union Carbide Canada to build a 2 billion lb E3 plant, a proposal that was subsequently expanded to 2.8 billion lb.

Market

These partnerships also create nearby markets for E3's ethylene, a commodity that is not easy to ship long distances.

BP Amoco's on site LAO plant acts as both a customer of, and supplier to, Nova Chemicals. Much of Union Carbide's half of E3's production will be piped a few miles to feed its ethylene glycol plant and new polyethylene plant at Prentiss, Alta.

A new pipeline will also ship E3 ethylene 100 miles north to supply Dow Chemical Canada and Shell Chemical Canada petrochemical facilities near Edmonton. Nova Chemicals' PE2 and PE1 plants will consume most of the remaining E3 production. Propylene and other coproducts will be shipped by rail to other Canadian and U.S. markets.

"Once all the new derivative plants in Alberta are completed, we will have local markets for all the ethylene we produce from E3," says E3 manufacturing leader Eric Wade.

By contrast, the markets for Joffre's PE2 pellets are global, embracing North America and the Pacific Rim. With PE2, the strategy is to apply PE2's Advanced Sclairtech technology to convert low-cost feedstock into superior resins that sell for a premium and help build licensing revenues.

"Polyethylene is what pulls Nova Chemicals' ethylene through the system, and it's a commodity that has shown substantial continuous growth above GDP levels," says Ferris. "With Asian economies now turning around, the demand for polyethylene continues to be strong, particularly for new and improved applications."

Engineering and construction

The Joffre 2000 project posed considerable challenges for an international team of engineering firms charged with designing and overseeing the simultaneous construction of three facilities.

The project's engineering costs were $275 million, which involved more than 2-million man hours of engineering. Teamwork was essential.

Basic engineering for E3 began in 1996 by Stone & Webster Engineering Corp., Houston. To facilitate the subsequent detailed engineering, procurement, and construction work, the firm formed a joint venture with Fluor Daniel Canada in early 1998, called C2 Plus. Stone & Webster worked on E3's furnaces from Houston, and Fluor handled the rest from Calgary.

"They are the biggest ethane cracking furnaces Stone & Webster ever designed and managed construction. E3's furnaces are 2.5 times larger than the ones in the E2 plant," says John Stuart, project leader of the E3 joint venture. "Everything-the pipes, furnaces, pipe racks-is big."

Toronto-based Stone & Webster Canada Ltd. undertook the basic engineering for PE2 in 1996. A year later, it started the detailed engineering in a joint venture with Colt Engineering, Calgary.

While PE2 was a smaller plant than E3, the engineers shared a similar task of designing, procuring, and fitting together large pieces of equipment.

"There have been some major engineering challenges," says Gerald Kiffiak, project leader of Advanced Sclairtech at Joffre. "Not only are we building the first commercial plant in the world to use the Advanced Sclairtech technology, it is the largest solution plant ever built. Some of the equipment required is the largest the vendors have ever built. Some of the heat exchangers, for example, are the largest of their type, as are the rotary dryers for the pellets. The Krupp Werner & Pfleiderer single-line extruder that will produce the plant's polyethylene pellets is the largest of its kind in the world."

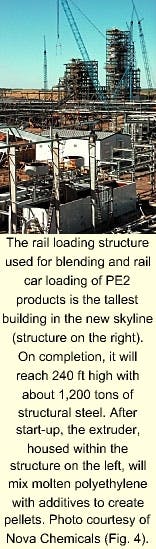

Fig. 4 shows a photo of the PE2 plant and extruder.

Bantrel Inc., Calgary, oversaw the engineering, procurement, and construction of Joffre 2000's various infrastructure components. "The team faced a tight timeline," notes Keith McLeod, Nova Chemicals project leader for infrastructure and cogeneration. "The infrastructure design, which had to be in place before the new plants commenced operations, had to wait for the requirements coming out of the new plant designs."

Construction of Joffre 2000 began in mid-1997 with underground piping, piling and foundation work, and the start of the E3 plant. Building of PE2 and cogeneration plants followed in 1998, and the construction of BP Amoco's LAO facility followed a year later.

To ease congestion on a crowded construction site, about 15% of the expansion's equipment was built in modular fashion and then transported to Joffre for final assembly. This work included substations, huge pipe racks, and a 1.5 million lb, 300 ft C2 splitter, which was transported in 3 days from Edmonton, Alta. Transportation required construction of a temporary bridge for a river crossing.

At one point, the Joffre site had more than 50 cranes (Fig. 5).

Safety, workforce, and environment

Safety performance is a key area. The project management team set a target of achieving an away-from-work case rate of less than 1.5 injuries/200,000 working hr. This goal was half the historical rates achieved by the best similar construction project in Alberta.

Through owner participation and contracting practices and measures like ongoing worker training and safety audits, the projects have surpassed this performance. They have achieved an impressive 0.5 case rate during 3 years with more than 12 million construction hr worked.

The construction workforce peaked at more than 4,500 in late 1999, with nearly 2,200 workers living in an on-site camp that provided convenient housing. The camp also helped to reduce vehicle traffic in the surrounding rural community.

Nova Chemicals employed an innovative system of tractor-pulled custom trams to efficiently and safely move workers to and from the job site and minimize traffic on the busy site.

Nova Chemicals took a proactive approach to minimizing the impact of the project on the surrounding rural community and environment. The company held numerous meetings with area residents and conducted extensive environmental impact assessments.

The project took pains to minimize the impact of heavy equipment and passenger vehicle traffic to and from the construction site. To fulfill a commitment that the post-construction site would be no louder than before expansion, the company invested more than $7 million in such noise mitigation measures as installing in-line silencers in exhaust stacks, specifying quiet cooling tower fans, and housing louder pieces of equipment inside buildings.

Another environmental-protection measure involves containing rainwater that falls on the paved processing area, removing any hydrocarbon contamination, and then recycling the water for use in cooling towers.

Increasing the size of the facility also resulted in increased monitoring of many environmental parameters such as ambient air quality and water discharge quality.

As construction on the Nova Chemicals plants enters the final stages, attention shifts to the extensive process of commissioning the facilities. At the same time, operating staff is gearing up for operations with the help of a training simulator.

"It simulates how the plant will react so operators can get a feel for how it runs under normal and unusual operating scenarios," says Kiffiak. "The simulator is particularly valuable for the PE2 plant because it trains the operators on a process they've never run before, in terms of dynamics. They need to think differently to operate it and they need to learn the process intimately."

Some 80 Nova Chemicals employees will operate each of the PE2 and E3 plants, with as few as half-dozen people required during each shift. The entire expanded Joffre site will have an operating staff of close to1,000.