Equipment/Software/Literature

Directional Drilling Software

3D3 Planner is a new, advanced directional borehole/well planning and survey management software program mainly used for designing 3D trajectories for oil, gas, and geothermal wells. In addition, it's also used for planning the design and installation of pipelines by horizontal directional drilling.

Its spreadsheet style system allows the use of "what if" scenarios to speed up the planning process

Unlimited multitarget capability and 2D and 3D well profiles of varying styles and sizes can be defined and incorporated into the plan.

Predefined 2D-3D profiles can be combined to build complex geometries and enable an engineer to develop proposals for all possible well scenarios with minimal effort.

The program's survey calculation uses three borehole/well trajectory models.

There's a spreadsheet style user interface with 2D and 3D graphics.

Enhanced graphical plotting includes 3D, top and section views, perspective effect, real time rotation, paneling, zooming, and proximity effects, and user defined graph and line properties.

Source: Technical Toolboxes Inc., Box 980550, Houston, TX 77098.

New liquid level switches

New Identisense PD-1O1 Series liquid level switches are designed to replace mechanical float type liquid level devices for high level alarm.

Switches promise reliable operation in virtually any liquid including all 16 hydrocarbons, regardless of viscosity, which eliminates the problem of stickiness and failure rate due to finite mechanical life inherent into the mechanical float design, the company points out. With fully epoxy sealed electronics, combined with ultrasonic sensing technology, the Pd-101 is designed for years of maintenance-free service. Units offer a variety of outputs and are available in a range of materials to meet a spectrum of difficult environmental applications.

Switches have integral electronics with 6-30 v dc input power with transient reverse polarity protection. Different outputs are available such as two wire loop power type, relay output, and source or sing current types.

Source: Cosense Inc., 155 Ricefield Lane, Hauppauge, NY 11788-2007.

Corrosion-measurement tool

The risks and costs associated with measuring corrosion under "hidden areas" such as pipe supports have been reduced with the introduction of a new pipe support tool.

The device, which offers an alternative to the process of inspecting pipes by lifting them off their supports, uses long-range ultrasonic measurements to establish pipe metal loss at each support. This technique could result in savings in operational costs because refinery and offshore operations can be kept on-stream during measurements. It also eliminates the hazards associated with using a crane to lift pipes that may already be weakened by corrosion, the company points out.

The tool measures corrosion losses of more than 30% of the thickness on pipes ranging from 2 to 18 in. in diameter and having a wall thickness of 5-15 mm. The hand-held device is made from standard components and is easy to use by staff trained in nondestructive testing.

In operation, the tool is placed on the top of the pipe, above the support. Its two probes straddle the pipe at about the 12 o'clock position. One probe transmits an ultrasonic beam into the steel at an angle that ensures the signal passes through the pipe wall by reflection from the inner and outer walls. When local wall loss is encountered, the signal transmission is hampered, resulting in a decrease in signal at the receiver that enables the metal loss to be determined.

Source: Shell International Ltd., Shell Centre, London, SA1 7NA, England.

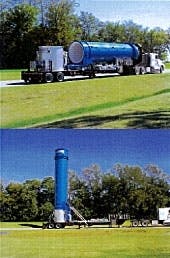

Rental combustion fleet expanded

An expanded fleet of portable combustion equipment provides units with larger capacity and more flexibility in their trailer-mounted systems.

Two more of these self-contained portable emission control system (PECS) units debuted recently.

The design of the units enables them to move from one job site to the next fairly easily, helping minimize field work required to put the system into operation. However, the capacity of these systems is constrained by the forced draft air blower that is reqired to supply the combustion air.

The new PECS units are vertical in design and incorporate integrated hydraulic systems permitting vertical stacks that can be raised and lowered at the job site without the use of a crane. The company says these vertical systems allow for higher air induction capacities via natural draft.

Source: John Zink Co. LLC, Box 21220, Tulsa, OK 74121-1220.