Supersonic gas separation held out for offshore gas conditioning

Hope for large offshore gas separation and conditioning that doesn't require much platform space nor produce pollution got a boost at the Offshore Technology Conference in Houston.

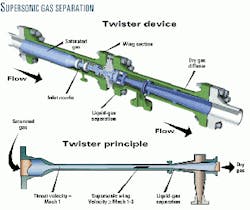

Twister BV, the Netherlands, with Shell Technology Investments Partnership, showed off a gas-separation technology based on supersonic gas velocities.

No chemicals

Twister CEO and Technical Director Kees Tjeenk Willink, in a press conference on the technology, said that the Twister device (diagram) takes up far less space on an offshore platform than conventional glycol or methanol-based processing and uses no chemicals nor produces substances that must be handled with costly recovery and disposal.

Twister Technology Development Manager Fred Okimoto explained that saturated natural gas is expanded in a Laval nozzle, which creates supersonic velocities and cryogenic temperatures.

The low temperature creates fog-like liquids, typically a mixture of water and heavy hydrocarbons. A wing generates a high swirl, which forces the liquids to the wall of the device and thereby separates gas and liquids.

The dry gas continues out of the device and, said Okimoto, meets requirements for power plants or residential use.

Dry-climate application

The Twister has been tested in three gas plants at full flow: in Holland, at Zuiderveen and Leemens in the Groningen field, and at Barendrecht near Rotterdam.

At present, the technology is only available for gas dehydration, hydrocarbon dewpoint, and C5+ recovery markets. Further, it is currently only able to be marketed in warmer climes or in applications with relatively relaxed specifications.

Marketing in the US and Europe is targeted in 2001.

Future applications envision H2S removal as well as subsea separation.