Geologic CO2 sequestration may benefit upstream industry

Should restrictions on carbon dioxide (CO2) emissions arise, operators in the upstream petroleum industry with the right technology and reservoir access will be positioned to benefit from the emerging geologic sequestration industry.

Highly mature regions, such as the US Permian basin, may someday realize more revenue from CO2 disposal than from oil production. This scenario is more likely today than imagined even 5 years ago.

About 190,000 b/d of US oil production come from enhanced oil recovery projects using CO2 injection. Uniquely, these EOR projects dispose (or sequester) CO2 at overall net profit and without subsidy. In the future, these fields may be reconfigured to maximize CO2 injection, the opposite of current practice.

Global warming is still hotly debated in scientific circles, but no one disputes the fact that atmospheric CO2 levels are climbing steadily. Many attribute this rise to growing energy consumption. Yet, the irony is that the global oil and gas industry has the tools for containing the growth in emissions with the emerging technology called geologic sequestration.

Such energy companies as BP Amoco PLC and Texaco Inc. have stated publicly that research and development aimed at reducing CO2 levels may help to avert serious consequences in future centuries.

Legislation proposed in Congress would prequalify sequestration activities for future emissions credits. And some view sequestration to be a major business opportunity in which prescient operators will have competitive advantages.

A recent study by Advanced Resources International Inc. (ARI), Arlington, Va., for the International Energy Agency's Greenhouse Gas R&D Programme assessed the potential for sequestering CO2 in depleted oil and gas fields worldwide.1

Key issues addressed included:

- What is the global CO2 storage potential and where is it located?

- What are the likely costs?

- What obstacles, technical as well as business, confront sequestration in oil and gas fields?

Sequestration technology

Aside from reducing energy use or converting to low or no carbon energy fuels, an effective way to reduce emissions to the atmosphere is to capture CO2 at the source and sequester it over a long time, preferably thousands to millions of years.

Storage is possible in several media such as trees, the deep ocean, aquifer systems, underground coal seams, and depleted oil and natural gas fields.

Arguably, depleted oil and gas fields offer the most favorable sequestration sites. These fields are proven long-term traps for fluids and gases, including CO2. Dense webs of seismic and well control delineate many of them. Surface and subsurface infrastructures exist and could readily be converted for CO2 distribution and injection.

By comparison, other sequestration methods, such as reforestation or deep-ocean injection, are experimental and may be less permanent, harder to verify, and more costly.

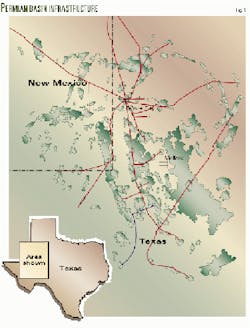

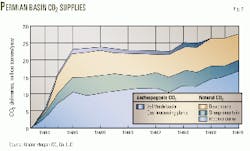

CO2 sequestration already occurs on a significant commercial scale, unintentionally, within the enhanced oil recovery (EOR) floods of the Permian and a few other mature oil basins (Fig. 1). More than 25 million tonnes of CO2 are effectively sequestered annually in the Permian basin to recover nearly 150,000 bo/d (Fig. 2).2

Several EOR projects sequester CO2 supplied by anthropogenic (manmade) sources, such as gas processing and fertilizer plants (Table 1).

Depleted natural gas fields are also feasible sequestration targets. Without offsetting revenues from enhanced recovery, however, these are more costly settings.

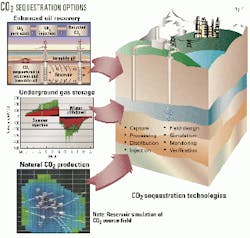

Of particular promise is the potential to apply existing petroleum technologies to sequestration projects, with relatively minor adaptation (Fig. 3). Three mature industry activities have such off-the-shelf potential:

1. Enhanced oil recovery. EOR projects can sequester CO2 at a net profit in favorable reservoir settings.

Major CO2-EOR areas include the Permian and Rocky Mountain basins, in which the industry has more than 25 years of continuous operational experience. CO2 floods are still rare outside North America, but geologic conditions are appropriate in many of the world's depleted oil fields.

Technologies particularly relevant to sequestration include CO2 processing and injection, field screening and flood design, reservoir simulation, observation wells, tracers, and 4D seismic monitoring.3-5

On average, EOR projects consume 4-8 Mcf of CO2/bbl of enhanced oil recovered.

2. Underground gas storage. UGS is an integral component of natural gas pipeline delivery systems. Originally configured for methane storage, many UGS technologies, such as reservoir management, injection strategies, and slim-hole observation wells, have cross-over potential to sequestration.6

Most UGS sites are depleted natural gas fields, a reservoir class with an estimated 800 billion tons of CO2 storage capacity. Others are aquifers or depleted oil fields.

More than 400 UGS facilities are currently in operation in North America and another 100 facilities in Europe.7 8

3. CO2 production. Pure, naturally occurring CO2 deposits, such as McElmo dome in Colorado and Jackson dome in Mississippi, currently supply most of the injectant used in EOR projects, about 1.5 bcfd.

These deposits are unique natural laboratories for investigating the long-term physical and geochemical effects of CO2 sequestration on reservoirs and aquifers.

The specialized production and monitoring techniques and equipment developed to handle corrosive CO2 safely and to understand its movement in a reservoir could be adapted for future sequestration operations.9

Best practices for adapting these three existing technologies for sequestration are still under development. Pioneering R&D is under way by the US Department of Energy, the IEA Greenhouse Gas R&D Programme, the Australian Petroleum Cooperative Research Center, as well as other research groups and individual operators.

A coordinated set of research-quality field pilots and demonstrations could greatly accelerate the availability of efficient, low-cost sequestration technology.

Incentives spark projects

Norway is the only country that directly taxes CO2 emissions and then only for offshore oil and gas operations. Currently, this tax amounts to $53/tonne, which is considerably higher than market alternatives for disposing of CO2.

Norway's emissions tax has encouraged Statoil to capture, process, and reinject CO2 at its Sleipner field in the North Sea. The Sleipner program is the first dedicated geologic sequestration project in the petroleum industry.

Since 1996, Statoil has injected nearly 4 million tonnes of by-product CO2 into the Utsira formation, a regional aquifer. An international consortium is monitoring the project to optimize aquifer sequestration technology.10

In Canada, the Greenhouse Gas Emission Reduction Trading (GERT) pilot, a partnership of government and industry, is testing the mechanics of a future national trading system.

Also in Canada, a major new EOR project is under development at the Weyburn oil field in Saskatchewan.11 While not the first EOR project to sequester anthropogenic CO2, nor the largest, Weyburn represents a major advancement in monitoring and monitizing sequestration.

Operator PanCanadian Resources plans to sequester 20 million tonnes of CO2 to recover an estimated 130 million bbl of oil. CO2 will come from the Great Plains coal-gasification plant in Beulah, ND. A 330-km pipeline is nearly complete. CO2 injection is scheduled to begin in October 2000.

The US accounts for more than 90% of CO2-EOR production, but no emissions incentives exist to reward operators. House Bill HR2520 (and previous Senate Bills S547 and S2617), introduced in 1999, proposes to provide operators with tradable credits for reducing greenhouse-gas emissions under future and as yet unspecified regulations.12

The free market is already determining the value of emission credits. In one recent transaction, Ontario Power Generation Inc. purchased the rights to emit 2.3 million tonnes of CO2 equivalent from a US landfill methane operator. Credits were valued at about $9/tonne or $0.50/Mcf.13

At this transaction price, emissions credits could offset much of the supply cost for CO2 at a typical EOR project, where CO2 purchase is the largest operating expense.

Costs, potential

The costs or profits of sequestering CO2 in depleted oil and gas fields can be attractive, compared with alternative disposal options. Costs are expected to range widely, depending on reservoir conditions and proximity to CO2 sources.

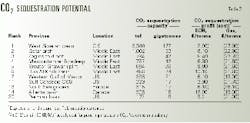

In the most favorable areas, such as Permian basin EOR projects, CO2 can be sequestered at substantial net profit. For example, based on the current price of $0.65/Mcf for high-pressure CO2 and 1999 oil prices of $15/bbl, operators are sequestering CO2 at a profit, thanks to incremental oil recovery (Table 2).

Other settings, however, such as oil fields remote from CO2 sources and depleted natural gas fields, represent more-costly sequestration targets. These fields may incur sequestration costs of $20-40/tonne, still moderate compared with other disposal alternatives.

The ARI study estimated the worldwide capacity and costs of CO2 sequestration. In the study, a global economic model of the largest 155 petroleum provinces, was constructed using petroleum resource databases recently developed by the US Geological Survey.14 Cost data were based on actual Permian basin CO2 flood costs,1 adjusted for market conditions in each province.

Key assumptions included:

- CO2-to-EOR ratios of 6.0 Mcf/bbl (miscible) to 10 Mcf/bbl (immiscible).

- $15/bbl oil price.

- Empirical EOR recovery to oil gravity and CO2:methane volume and pressure ratios.

Given the long-term time frame of sequestration (several centuries), petroleum recovery infrastructure was assumed to develop in most worldwide basins.

Global sequestration capacity in depleted oil and gas fields is substantial, an estimated 923 gigatonnes (109 tonnes). This equates to 125 years of current worldwide CO2 emissions from fossil fuel-fired power plants.

Fig. 3 shows the distribution of sequestration capacity and costs for all 155 provinces, while Table 2 highlights selected provinces. Natural gas fields have larger capacity than oil fields because the resource base is larger and gas fields are deeper on average.

The largest cost for sequestration is to capture, process, and compress anthropogenic CO2 to prepare it for use by the oil or gas field operator.

Power-plant flue gas is the most costly source to process, estimated at $53/tonne ($3.00/Mcf) with current technology. Waste CO2 from natural gas processing or fertilizer plants is less expensive ($18/tonne or $1/Mcf). But both are more costly than natural CO2 prices (about $0.65/Mcf).

Capture technology, however, is considered immature and costs could fall rapidly with R&D.16

Barriers to implementation

Despite the promise of geologic sequestration, a number of barriers confront more widespread implementation of this environmentally benign technology in depleted oil and gas fields. These barriers include:

- High capture costs. The most important barrier is the high cost of capturing and processing CO2 from anthropogenic sources, estimated at $1-3/Mcf.

R&D is under way in advanced amine, membrane, and cryogenic separation to reduce costs. Reconfiguring future power plants to concentrate CO2 in flue gas would dramatically reduce capture costs.17

- Incomplete reservoir understanding. The near-term (10-30 years) view of EOR and UGS need expanding to the thousand-to-million year time scale required for sequestration. A study of natural CO2 fields could provide insight into cap-rock integrity and long-term interaction between CO2 and reservoir rock and fluids.

- Monitoring and verification. For emissions-reduction credits to count, rigorous monitoring and verification of sequestration is essential. EOR and UGR monitoring technologies, such as geochemical tracers, reservoir simulation, observation wells, and advanced 4D seismic, could form a basis. The excellent safety record of industry in handling CO2 deserves recognition.

- Emissions trading. The most efficient means for achieving emissions reductions is a globally functioning trading system. Such a system currently does not exist and industry has a proactive role in shaping it.

- Sequestration and production conflicts. The objectives of sequestration may clash with production operations (such as optimizing the CO2-to-EOR ratio). Injecting CO2 earlier in the life of the oil field is unconventional but could enhance both sequestration and oil recovery. Such conflicts need further study.

Acknowledgment

The authors thank the IEA Greenhouse Gas R&D Programme and the US Department of Energy for funding this study. We also wish to thank numerous petroleum operators who contributed ideas and data for the study.

References

- Stevens, S.H., Kuuskraa, V.A., and Taber, J.J., "CO2 Sequestration in Depleted Oil and Natural Gas Fields," IEA Greenhouse Gas R&D Programme, IEA/CON/98/31, 1999.

- Moritis, G., "EOR weathers low oil prices," OGJ, Mar. 20, 2000, pp. 39-61.

- Taber, J.J., Martin, F.D., and Seright, R.S., "EOR Screening Criteria Revisited-Part 1: Introduction to Screening Criteria and Enhanced Recovery Field Projects," SPE Reservoir Engineering, August 1997, pp. 189-98.

- Benson, R.D. and Davis, T.L., "4-D, 3-C Seismic Put to Task in CO2 Huff-And-Puff Pilot," American Oil and Gas Reporter, February 1999, pp. 87-94.

- Gunter, W.D., Chalaturnyk, R.J., and Scott, J.D., "Monitoring of Aquifer Disposal of CO2: Experience from Underground Gas Storage and Enhanced Oil Recovery," Fourth International Conference on Greenhouse Gas Control Technologies (GHGT-4), Interlaken, Switzerland, Aug. 30-Sept. 2, 1998.

- Schoell, M., Jenden, P.D., Beeunas, M.A., and Coleman, D.D., "Isotope Analyses of Gases in Gas Field and Gas Storage Operations," Paper No. SPE 26171, SPE Gas Technology Symposium, Calgary, June 28-30, 1993.

- "Survey of Underground Storage of Natural Gas in the United States and Canada," AGA, Washington, 1999.

- "Natural Gas Information 1998," International Energy Agency, 1999.

- CO2 Plants and Facilities," University of Texas of the Permian Basin Conference, Midland, Tex., Dec. 8, 1998.

- Baklid, A., Korbol, R., and Owren, G., "Sleipner Vest CO2 Disposal, CO2 Injection into a Shallow Underground Aquifer," Paper No. SPE 36600, SPE Annual Technical Conference and Exhibition, Denver, Oct. 6-9, 1996.

- Weyburn Monitoring Workshop, University of Regina, Sask., Aug. 26-27, 1999.

- "Credit for Voluntary Actions Act," US House of Representatives, HR2520, introduced by Rep R. Lazio, July 14, 1999.

- McKay, P.A., "U.S. Landfill Concern, Ontario Utility Agree to Swap Gas-Emission Rights," Wall Street Journal, Oct. 26, 1999.

- Masters, C.D., Root, D.H., and Turner, R.M., "World Conventional Crude Oil and Natural Gas: Identified Reserves, Undiscovered Resources and Futures," US Geological Survey Open-File Report 98-468, 1998.

- Fox, C., "The Permian Basin CO2 Supply," CO2 Oil Recovery Forum, New Mexico Institute of Mining & Technology, Socorro, NM, Oct. 23-24, 1996.

- Herzog, H., "The Economics of CO2 Capture," Fourth International Conference on Greenhouse Gas Control Technologies, Interlaken, Switzerland, Aug. 30-Sept. 2, 1998.

- "CO2 Capture and Geologic Sequestration: Progress Through Partnership-Workshop Report," BP Amoco, Houston, Sept. 28-30, 1999.

The authors-

Scott H. Stevens is vice-president of Advanced Resources International Inc., Arlington, Va., an upstream petroleum geology and engineering consulting firm. He is involved in evaluating petroleum development projects and conducting R&D on geologic sequestration technology.

Formerly Stevens was with Texaco and Getty International. He holds graduate degrees from Harvard and Scripps Institution of Oceanography.

John Gale is project manager responsible for geologic sequestration technology development with the International Energy Agency's Greenhouse Gas R&D Programme.