Novel insulated production system planned for deepwater Angola field

Alto Mar Girassol last month was slated to begin construction of an innovative system of heavily insulated flowline bundles and rigid riser towers for development of TotalFinaElf SA's Girassol deepwater giant oil field development project off Angola, in 1,350 m of water.

Alto Mar Girassol is a joint venture of Bouygues Offshore SA and the newly merged Stolt Comex Seaway SA and ETPM SA. The system, which will be built entirely in Angola, will link the 40 subsea Girassol wells to surface facilities on offshore Block 17.

TotalFinaElf unit Elf Aquitaine discovered Girassol in 1996 and followed that with five other significant field discoveries on the block. Combined reserves of the six fields are estimated at 3.5 billion bbl, and ultimate block development cost could reach $8-10 billion over 10 years (OGJ, Oct. 18, 1999, p. 38). Girassol, in 2001, will be the first field to start producing. Production is expected to plateau at about 200,000 b/d for 5-6 years.

Girassol development entails subsea wells tied back to a floating production, storage, and offloading vessel (FPSO).

Insulation project details

The paraffinic Girassol crude oil will leave the wellheads at 65° C and flow through 7 km of horizontal, bundled flowlines and then vertically to the top of the 1,300-m riser towers in 4° C seawater. The bundles and riser towers will have to submit to 20 years of wear while maintaining sufficient insulation quality to meet the thermal challenge of deep water. Over the past year, the basic equipment design has undergone $10 million of insulation-qualification tests in a technology center near Paris.

Without insulation, the average horizontal heat loss would be 18° C/km and the average vertical heat loss would be 10-12°C. When the Girassol crude temperature drops below 40° C, it is likely to deposit paraffin along the line, and when it drops below 20° C, hydrates are likely to form. That increases the risk of flowlines plugging up. To keep from plugging the lines, oil must reach the Girassol FPSO at no less than 40° C.

Unacceptable heat loss must be countered through an insulation system that brings the average temperature loss to no more than 1° C/km.

Flowline insulation has been designed and tested to maintain the 27-km of crude- oil gathering network at a temperature in excess of 40° C. To prevent hydrate formation in case of production shutdown, the isolation design ensures a minimum 20° C. for 16 hr.

Flowline bundles

Each flowline bundle consists of two production lines, each 8-in. ID, set in two half-thermal isolation sleeves belted together with tension straps rated at more than 2 tonnes. These lines are inserted in a 30-in. steel carrier pipe.

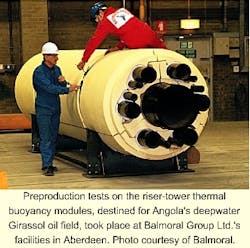

The insulation sleeves are made of rigid epoxy-based, high-thermal-performance, high mechanical-resistance foam containing micromarbles for better resistance to pressure. Balmoral Group Ltd. manufactures the resin foam containing micromarbles. The foam is a resin containing micromarbles (see photo). The foam costs $5,000/cu m, and the contract requires more than 10,000 cu m.

The bundle prototype tested was 12-m long (4 half sleeves of 6 m ) and weighed more than 10 tonnes. The test-bench assembly facilities consisted of a basin 15 m long and 1.4 m in diameter, with a capacity of 24 cu m of 4° C water circulating at 30 cu m/hr. Every 30 sec, the data acquisition system registered the information provided by 120 sensors, involving 3 million measurements in one cycle of four tests.

Electric power carried in the production lines was regulated by an automatic and a manual system. The technicians measured the electric power needed to maintain the oil at 55° C. This electric power corresponded to the heat loss of the bundle sunk in water at 4° C. This makes it possible to test the thermal insulation characteristics of the system.

Heat loss measurements were carried out over a 9-day, complete-cycle test with one or two lines in production. The cooling liquid spans were about 60 hr, higher than required. The lab also simulated a production shutdown.

Riser towers

The riser tower behavior is complicated. Each of the three slender towers will be 1,300-m high and encompass four production lines kept vertical by a central core, two injection lines, and two gas-lift lines, as well as service lines (for chemical injection). The same foam as the bundles will hold the lines all together.

The bundles, in lengths of 250 m, will be strung along to a total length of 3 km. Alto Marc Grissol will manufacture the bundles at its logistics base in Soyo, Angola, at the mouth of the Zaire River. Following reconnaisance of the route for obstacles, Alto Marc Grissol will have the bundles towed with floaters through a channel to the ocean, then along the seabed to the production site. The carrier pipe is coated with a 6-mm metallic layer as well as a 7-mm polypropylene sheath to withstand seabed friction.

The three riser towers will be built in Lobito at an ETPM yard. They will be stored there and surface-towed to the site, where they will be placed vertically and anchored with vacuum anchors, each 20 m high and 8 m in diameter and shaped somewhat like an upturned drinking glass. These suction anchors are to be sunk in the seabed, and they will also help anchor the manifolds. All told, about 40 suction anchors will be used.

Bundle and riser construction was to begin in March and April and be completed by yearend 2000. In a first stage, nine bundles will be manufactured and towed to the site in early 2001. The risers were scheduled to be installed in April and May. By the time the FPSO arrives, in May or June, the only thing left to be done will be the installation of the 60 km of flow lines and 70 km of umbilicals.

Development

This project covers the first stage of Girassol development, intended to recover about 725 million bbl of oil.

A second development stage is being studied for development of another 300 million bbl of oil. That stage will require installing additional bundles, bringing the total to 13-14 bundles. Location of the second lot yet to be decided.

Two drilling rigs were slated to begin drilling the 40 wells planned for the project in April or May. It will take 3 years to drill all of the 23 oil production wells, 14 water injection wells, and 3 gas injection wells.