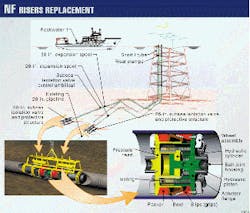

Isolation valves aid Bombay High riser replacements

UNDER A CONTRACT FROM OIL & National Gas Corp., Bombay, Asian Marine Contractors (AMC) recently completed replacement of two risers and subsea isolation valves on the NF platform, Bombay High, with use of remotely operated pipeline isolation systems.

AMC, a subsidiary of Halliburton Co.'s Brown & Root Energy Services, Houston, says this is the first time in the world that such state-of-the-art technology has been used subsea for online replacement at such high pressure.

Two modules

The turnkey contract, says AMC, recognized the need to reduce production loss from Bombay High during the riser change out and subsea valve installations. The risers and valves were installed with hyperbaric welding techniques from Brown & Root's DSV Rockwater 1.

AMC in turn awarded a contract for design, manufacture, and operation of remote-operated isolation plugs to Plugging Specialists International (PSI), Norway.

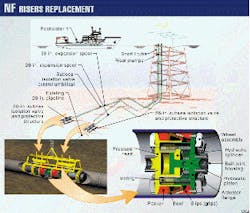

The remotely operated, computer-controlled isolation plug (Fig. 1) has two modules, each module having one set of grip and seal units to cater for complete redundancy. The isolation-plug system's pigging modules also encapsulated all the valves' hydraulic pumps and motors, microprocessor controllers, and battery.

Activation of gripping and sealing was done through remote sensing extra-low frequency (ELF) signals, activated from outside the pipe. This technology allowed the isolation system to be located a considerable distance from the platform and allowed the negotiation of a significant number of bends and pipeline fittings, says AMC.

Undertaken in October, the work included the installation of two subsea-isolation-valve skids, each with actuated ball valves and check valves, pipeline tie-in spools, replacement risers, control umbilicals, and replacement topsides pipe spools.

The pipeline tie-ins were completed in record time, according to AMC, with the NF platform being shut-in for 13 days for the gas-pipeline shutdown and 14 days for the oil line shutdown against a scheduled shutdown of 25 days for each.