'Delivering The Limit' Work-Flow Process Advances Industry's Push For Continuous Performance Improvement In Well Operations

Shell Expro, in partnership with key contractor companies, has introduced a new concept for delivering continuous performance improvement in well operations through a step change in partnering and real-time database systems.

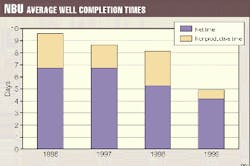

To date, the concept of Delivering the Limit (DTL) has achieved a reduction of 3.4 days for average well completion times, with all real-time operational data and lessons learned captured with the EGIS SmarTrak database system.

In addition, the DTL concept plays a key role in an agreement between Shell Exploration & Production Co. and Chevron U.S.A. Production Co. to share drilling rigs on their respective Gulf of Mexico deepwater exploratory drilling programs this year (OGJ, Feb. 14, 2000, p. 28).

Process driver

On a worldwide basis, Royal Dutch/Shell operating units are aggressively competing for limited capital funding while, at a local level, Shell Expro continues to drive for top-quartile performance.

This move away from major investment has an impact on the contracting community with whom Shell Expro so closely works. This has meant creating the right environment necessary to challenge the paradigms and "sacred cows" that were allowed to exist.

Shell Expro Northern Business Unit (NBU) operates a net work of nine installations in the East Shetland basin, with production of around 260,000 b/d of oil. EGIS is the lead well services contractor on Dunlin, Cormorant Alpha, North Cormorant, Tern, Eider, and the four Brent platforms. EGIS, which is part of Expro Group International PLC, provides integrated well engineering and project management services. Specifically, EGIS's scope of service in the NBU is to provide integrated well services management.

Operator and principal contractor organizations have strived to deliver continuous performance improvement in well operations. This has been through singular focus on reducing nonproductive time (NPT), which has delivered some improvements but not the required step-change essential for industry survival.

The DLT concept introduces two new definitions (Fig. 2). The first, Technical Limit (TL), is a term given to optimum operational performance under perfect conditions but without existing paradigms; it is used now by Shell Expro as a baseline reference point for planning and execution of well-construction projects. A close analogy of TL is a world record in athletics.

Invisible Lost Time (ILT) is nonproductive time related to conditions and activities within control of well operations. Prior to introduction of DTL, ILT was not recorded but just included in the productive time for well operations.

The DTL concept requires a special environment in which client and contractor personnel work together to deliver that improved performance: no finger-pointing, cover-ups, etc., just strong teams in pursuit of excellence and pride. This environment was achieved by Woodside Petroleum Ltd. in the mid-1990s, which then resulted in a step-change in that company's drilling and completion performance-average historical drilling times were halved and subsea completions were run in under half the benchmarked times.

NBU program

Shell Expro initially introduced the concept of DTL to its own staff and key contractor personnel through a series of workshops intended to foster challenges to existing paradigms. The initial focus was on Drilling the Limit, because drilling is a single, repetitive operation with visible subsets-each having readily identifiable targets of depth, time, ROP, etc. and all undertaken within a clearly defined work area. So far, the concept has delivered exceptional results:

- Dunlin Alpha well DA46 constructed 34% under planned time.

- Tern Alpha well TA12 constructed 30% under planned time.

- Combined cement scraper and stinger saved 1 day of rig time.

- Nonuse of casing protectors saved £120,000.

- Entire 81/2-in. hole section drilled as one (not two, as originally planned).

Applying DTL to well-intervention activities does present operational challenges, however, in particular where there exist differing well configurations and a varied range of intervention services and service providers.

DTL was introduced in well interventions also via a series of workshops with initial focus on well completion, which has since led to a radical review of procedures, practices, and methodologies. The application of DTL to well intervention has adopted the following process (provided under each step are specific examples that have contributed to a step-change in performance):

- Step 1: application of the TL technique to well completions. This included standardization of Northern Field Unit well completions, namely subsurface safety valve (SSSV) setting depth, the method used to set the production packer; challenging the need for specific steps, such as tubing-pressure tests; establishment of the TL and identification of actions to achieve this, for example, in christmas tree installation; and challenging the existing well design and introduction of alternative designs, e.g., a cemented monobore.

- Step 2: application of the TL technique to coiled tubing operations. This included establishment of the TL and identification of actions to achieve this, e.g., coiled-tubing run speed, and challenging the actual job design.

- Step 3: application of the TL to all other well-intervention operations, such e-line, slickline, braided cable, etc.

SmarTrak database system

A very important tool and key to the success of DTL is the provision and management of an effective database system.

The use of a dynamic database provides the facility for easy interrogation of well intervention operational data, and the ability to capitalize on the value of existing data enhances the successful implementation of DTL. Use of a database offers a wide range of operational time slices that contain information covering a wide range of well-intervention operations.

The database applied to well-intervention operations is SmarTrak. SmarTrak is a management tool developed by EGIS that allows operational improvement and real-time performance reporting to track that improvement.

The existing EGIS SmarTrak suite of programs have been modified and extended to become an efficient dynamic tool. A TL profile, in addition to planned and actual operations, can be generated for all well completions and associated intervention activities. Through SmarTrak, easy access and data entry enables the analysis of NPT and ILT on a real-time basis. SmarTrak has the added capability of full reporting facilities that allow "lessons learned" and " success gained" to be published quickly. Fig. 3 provides an example of SmarTrak output. Clearly identified against each step are the NPT and ILT recorded. An added feature is an indication of when the TL has been improved upon, or in other words, when the prevous record time for that activity has been beaten.

Results

In summary, applying DTL to well interventions has delivered outstanding results. A 39% reduction in the average Dunlin Alpha well-completion has been achieved. EGIS set a target of 25% improvement against 1998 average well-completion times of 8.2 days. Currently, 1999 average well completion times are running at 4.8 days. Fifteen were run in 1999 vs. 10 in 1998. Also, coiled-tubing run speed has been increased.

Among other results, NBU has managed to:

- Reduce SSSV setting depth. This saved on use of tubing, control line, and control line clamps and reduced running time. It will also save time on future well-intervention work.

- Use plug and check valve to set the production packer. This enabled the completion to be run without having to fill the tubing and eliminated two wireline runs from the standard completion.

- Need only one pressure test on tubing, packer, and "A" annulus to be performed after installation of the christmas tree.

- Capture real-time operational data via the SmarTrak database, which highlighted the different times needed to achieve christmas tree installation across the NBU platforms. A project is under way to establish the TL for this activity and identify the relevant actions required on each installation.

- Increase coiled-tubing run speed to 100 ft/min, if the hole has been adequately drifted before and a full CIRCA force and stress analysis has been performed by the coiled tubing contractor, BJ Services. POOH (pulling out of hole) speed has been increased to a maximum of 125 ft/min.

- Allow the evaluation for a wireline drift run on a case by case basis now. To properly assess the possibility of leaving out the drift run, all previous well entries are reviewed. If no problems were recorded-and a limited time span exists since the last well entry (up to 3 years)-then the drift run is omitted.

Conclusions

Shell Expro and key contracting companies have reacted positively to current market conditions and created the right environment to develop Delivering the Limit. This has been done by involving all key players. EGIS has invested futher in developing SmarTrak to provide a dynamic database system that can support DTL. A step-change has been achieved in well completion performance, and further work is under way to deliver the same on other well-intervention activities. Making DTL work involves considerable effort in the activity-planning stage, and hurdles continue to be faced, in particular regarding personnel management difficulties such as the following:

- The concept is hard to accept by people who have been part of the previous performance, particular when they realize that 30-50% of well completion times are removable.

- Reactions to DTL can vary from total dismissal to prolonged discomfort, as pride and confidence takes a real battering.

- Achieving less than 25% NPT is still viewed by some as an acceptable target.

- Applying TL can increase the risk of things going wrong.

- Deficiencies are exposed, thereby inviting criticism and invoking a blame culture.

These "soft" management issues have been minimized through effective introduction to DTL via workshops, involvement of all staff and contractor personnel, and a commitment by all to stay with the concept.

Acknowledgements

The authors would like to express their gratitude to EGIS Northern Business Unit team, for providing performance data; Ian Fraser, EGIS, for developing the SmarTrak database; and Shell and KCA for their valued input on this concept.

References

SPE 35077-Applying Technical Limit Methodology for Step Change in Understanding and Performance : D.F. Bond, P.W. Scott, P.E. Page, and T.Windham, Woodside Offshore Petroleum Ltd.

The Authors

Wouter Rensink is a well services professional with 20 years of industry experience. He joined Shell Netherlands in 1979 as a trainee well services supervisor and has since worked in a variety of well completion and well servicing roles for Shell E&P operating units in Australia, Thailand, Malaysia, and Oman. During 1989-91, he was head of well services at Nederlandse Aardolie Maatshappij BV, the Dutch joint venture of Shell and Exxon Corp. Before recently transferring to Petroleum Development Oman, Rensink was well services support engineer for the Shell Expro Northern Business Unit in Aberdeen.

George Galloway is a petroleum engineer with 14 years of experience in the UK continental shelf offshore oil industry. He graduated in 1985 with BSc (Hons.) in ofshore engineering from Heriot Watt University. Galloway worked for Mobil North Sea during 1985-93, mainly in well operations before joining Midland & Scottish Resources as a senior petroleum engineer. He left to join Expro Group Integrated Services (EGIS) in 1995, initially as well operations team leader on BP's Mature Assets unit and, more recently well operations manager for Shell Expro's Northern Business Unit. Galloway has recently moved to the role of group advisor within the parent company Expro.

Mark Brinsden graduated with a degree in geology from Edinburgh University in 1979 and joined Dowell as a technical engineer, working on a wide range of international services. He was a founder and technical manager of Petrocon well services in 1986, which was later purchased by Salvesen. He joined Prodrill Engineering in 1991 and served as general manager in Dubai. Smedvig Technologies purchased Prodrill, and Brinsden moved back to Aberdeen with Expro Group Integrated Services as well technology manager. He held an office with the Society of Petroleum Engineers in Dubai and was founder of two operator groups: the drilling technology group and the reeled systems technology users group. Brinsden has recently moved to the role of business processes manager within the parent company Expro.