U.K. nitrogen-removal plant starts up

Michael J. Healy, Adrian J. Finn, Les Halford

Costain Oil Gas & Process Ltd.

Manchester, U.K.

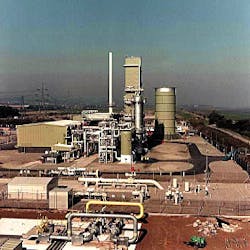

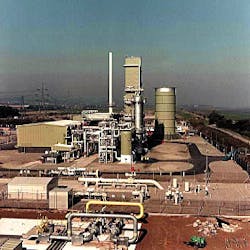

The gas-treatment plant at Connah's Quay, North Wales, U.K., is dominated by a view of the cold boxes, ground flare, and compressor house.

The £40 million natural-gas-treatment plant at Connah's Quay, North Wales, U.K., and owned and operated by the U.K. utility PowerGen, started up in November 1997. It processes up to 200 MMscfd of natural gas, reducing sulfur compounds and rejecting sufficient nitrogen to make the sales gas suitable for export to the U.K. National Transmission System (NTS).

This plant is part of projects for processing and commercializing natural gas from the Liverpool Bay development. It was designed, installed, and commissioned by Costain Oil, Gas & Process Ltd., Manchester.

Nitrogen is removed by cryogenic separation that employs the Joule- Thomson principle in a series of integrated distillation columns. This process was found to be optimal compared with less-sophisticated schemes and is sufficiently tolerant to CO2 to avoid an upstream CO2-removal step.

Costain undertook the project on a turnkey basis.

Four fields

The Liverpool Bay development ( Fig. 1 [91,485 bytes]) consists of four offshore fields in the Irish Sea off the North Wales coast. Although oil is exported directly from the Douglas platform, natural gas is brought ashore at the Point of Ayr terminal through a 20-in., 33-km subsea pipeline.The Point of Ayr gas terminal has a design capacity of 300 MMscfd. The inlet facilities remove methanol (used for hydrate inhibition), water, and condensate. The dry gas is then sweetened with an amine-based solvent. Hydrogen sulfide content is reduced to 3.3 ppm, mercaptans to 35 ppm.

The hydrocarbon dew point of the gas is reduced by a mechanical refrigeration unit to typical pipeline quality, and the gas is then exported through a 27-km underground pipeline at 30 bar along the North Wales Coast to Connah's Quay (Fig. 2 [68,302 bytes]).

Connah's Quay is the location of a new 1,430-megawatt, combined-cycle gas turbine power station. The fuel-gas requirement of 230 MMscfd leaves a surplus of 70 MMscfd in the pipeline from the Point of Ayr terminal. The gas required for power generation is routed through an aboveground installation directly to the power station.

The balance is passed to the gas-treatment plant where it is purified and compressed before being exported through a 30-in., 3-km pipeline under the Dee Estuary to Burton Point where it connects into the NTS.

The gas-treatment plant normally expects to process 70 MMscfd but has been designed to treat up to 200 MMscfd to cater for additional gas if the power station is operated at reduced capacity.

Process design

While the natural gas is of adequate quality for power generation, it requires treatment for the NTS. The Wobbe Index is less than permitted because of the high nitrogen content (up to 11%), and the level of sulfur compounds must be substantially reduced ( Table 1 [36,875 bytes]).A cryogenic process reduces the nitrogen content to less than 5% (Fig. 3 [100,610 bytes]). This process consists of a double distillation-column system with an upstream preseparation column to give low overall power consumption, a simple configuration of process compressors, and tolerance to carbon dioxide.

Such triple-column systems have been used previously in the U.S. and Western Europe for natural gas of similar nitrogen content.1 2 A rigorous evaluation of alternative process flowsheets concluded that this configuration was optimum for this particular application.

The heart of the process, cryogenics, requires deep gas drying. This is achieved by molecular-sieve adsorbers which are sized to remove not only water but also the sulfur compounds. Mercury is removed from the natural gas before the cryogenic section to protect the brazed aluminum heat exchangers.

The treated gas from the cryogenic section is compressed to NTS pressure and exported from the plant.

18-month turnkey

Costain's work included conceptual design and process optimization, basic and detailed engineering, procurement, construction, and commissioning.Along with the process plant, the contract included all necessary infrastructure: firewater systems, control building, power distribution, flare, sulfur-compounds incinerator, distributed control system (DCS), and process-safeguarding systems.

The project was undertaken on a fixed-price basis with PowerGen monitoring progress and performance against agreed "milestones" to ensure that contract intent was met throughout.

The critical path for the 18-month, fast-track schedule was specification and procurement of the sales-gas compressors and the design and fabrication of the cryogenic cold boxes.

The selected compressors were multistage centrifugal types. From both an economic and environmental standpoint, electric drives were selected. Costain's previous experience with such machines on hydrocarbon service and process development undertaken before contract award enabled procurement of these machines within the first 6 weeks of the contract program.

The cold-box designs required careful study early in the basic engineering of the project to ensure constructability was adequately addressed. The size and configuration of the heat exchangers, columns, separators, and pipe work required detailed evaluation to ensure the most cost-effective overall solution.

Transport and lifting limitations were considered in detail because of the restrictions of the site layout and limited access constraints.

To maintain project schedule, hazard and operability studies were completed early with a "design freeze" implemented by the fourth month of the schedule. This was key in ensuring the project schedule could be met at a controlled cost.

To afford maximum time for civil works and to minimize site-construction work, it was agreed that the plant should consist of several preassembled modules: 12 modules whose total weight exceeded 1,000 metric tons. The largest modules were the two cold boxes, key in ensuring satisfactory operation of the cryogenic process.

These were also critical items to the schedule. With overall shipping dimensions exceeding 49 m x 5.5 m x 4.5 m, transport and lifting logistics required detailed planning.

Use of a multidisciplined three-dimensional electronic model on plant-design management system (PDMS) reduced design detailing man-hours and enabled model reviews to be conducted rapidly, thus ensuring good layout, tight bulk-materials control, and error-free construction drawings (Fig. 4 [23,840 bytes]).

These were all factors in ensuring effective "single pass" design and construction in the least amount of time. Field and module rework was kept to an absolute minimum and represented less than 2% of costs with no program slippage.

The use of PDMS is especially valuable for cold-box design. It simplifies hydraulic analysis, enables layout to be generated and quickly assessed, and often results in reduced box size and cost (Fig. 5 [15,467 bytes]).

A reliability, operability, and maintainability (ROM) analysis of the complete plant was performed during the detailed-engineering phase with an in-house program linked to a database.

This step helped to target those plant areas with low availability so that solutions could be found to meet overall plant availability criteria. Overall plant availability is designed to exceed 98%.

Cold-box modules

The two cold boxes, shop-fabricated near the construction site, comprise complete package units in which aluminum plate-fin heat exchangers, distillation columns, separators, piping, and instrument-sensing elements are housed. The housing is a carbon steel frame, clad with plate ( Fig. 6 [31,629 bytes]).The equipment inside the cold boxes is a combination of aluminum and stainless steel. Exchangers are of aluminum alloys; vessels and distillation columns are of stainless steel. Cold equipment such as plate-fin exchangers are supported on stainless steel beams that are insulated from the carbon-steel frame via heat-resistant supports.

Similarly, heat-resistant supports are used between the carbon-steel frame and vessels mounted from the cold-box floor. The cold boxes stand on elevated piers, ensuring an air gap between the base of the box and the ground.

Piping between equipment is mostly of stainless steel with some aluminum. All piping connections are welded to prevent leakage from the process into the cold-box housing. Changes in pipe material from stainless steel to aluminum are made with proprietary design bimetallic transition pieces especially developed for the cryogenic industry.

All lines passing through the cladding are of stainless steel or similar material and terminate with external flanges. Cold lines that penetrate the cladding have specially designed and fabricated thermal shunts to protect carbon-steel plate from brittle fracture.

Insulation of the cold equipment is achieved by filling the internal void of the cold box with free flowing nonflammable expanded perlite after erection at site. To ensure a safe atmosphere in the cold-box housing, the internal void is continuously purged with dry nitrogen.

The cold-box housing is provided with a purge/pressure-control vacuum break system and protected by an emergency relief manway in case of process leakage.

Gas drying

Fig. 7 [86,007 bytes] shows the gas drying and sulfur-removal section.Molecular sieve is in three internally insulated vessels in a two-duty/one-regenerating arrangement. Water is removed to less than 1 ppm to prevent ice forming in the downstream cryogenic process. Hydrogen sulfide is removed to less than 1 ppm and total sulfur to less than 15 ppm to achieve sales-gas specification.

The molecular sieves are regenerated with hot waste nitrogen from the cryogenic section of the plant to desorb water and sulfur compounds that are then destroyed in a thermal oxidizer. The resulting sulfur dioxide is dispersed to atmosphere through a 45-m stack.

The design of this system was fully evaluated against the Best-Available-Technology-Not-Entailing-Excessive-Cost requirements of the U.K. Environmental Agency.

If, for any reason, one of the molecular-sieve vessels is unavailable, the control sequence enables plant operation to continue with two beds to ensure high availability.

The dry sulfur-free feed gas from the molecular sieves containing 8-11% nitrogen passes to the cryogenic nitrogen-removal system (Fig. 8 [96,244 bytes]) which produces a natural-gas stream containing less than 1.5 mol % nitrogen and a nitrogen-rich off-gas containing less than 1.5 mol % methane.

The depth of nitrogen rejection allows approximately 30% of the feed to bypass the cryogenic process and be sent directly to sales-gas compression, the NTS specification allowing up to 5% nitrogen.

The cryogenic process is based on two main separations. In the preseparation column, the feed gas is separated into a methane stream and a nitrogen-enriched stream suitable to be passed to the downstream double column system.

The preseparation column allows more than 50% of the methane to be separated and recovered at higher operating temperatures (-100? C.) than the downstream double-column system. This reduces the work of separation, hence minimizing sales-gas compression power,3 and it also increases tolerance to the carbon dioxide in the feed gas.1 4 5

Costain Oil, Gas & Process6 also applied this concept for the British Gas North Morecambe terminal farther north on the English coast.7 The preseparation step upgrades the nitrogen level and reduces the feed rate to the double-column system, which further improves the efficiency of the overall cryogenic process.

The associated reduction in column size and exchanger size for the double-column system reduced cold-box size and cost.

In the low-temperature, double-column system (Fig. 9 [96,199 bytes]), the nitrogen-enriched gas is separated (lowest temperature -185? C.) into the reject-nitrogen stream containing less than 1.5% methane and a low-pressure methane stream. This stream is pumped to 10 bar and passed to the sales-gas compressors.

A common methane reboiler/nitrogen-reflux condenser links the two columns operating at 25 bar and 1.5 bar, respectively. This double-column system resembles that employed extensively in oxygen production and avoids the need for complex heat pumps and excessive machinery.8 9

The Control of Industrial Major Accident Hazard regulations apply to the site, and the plant has operated in accordance with the Integrated Pollution Control requirements of the 1990 Environmental Protection Act.

This requirement dominated much of the thinking behind the process and engineering design.

Helium removal

The natural-gas feed to the gas-treatment plant contains up to 600 ppm helium. Although insufficient for economical recovery, the helium must be removed to prevent it blanketing the reboiler/condenser in the double-column system.A refluxing heat exchanger10 takes a vapor stream from the lower column condenser, using refrigeration from the rich liquid stream to condense out nitrogen and leaving a helium-rich purge stream.

The refluxing heat exchanger has the equivalent of several equilibrium stages and provides a 30% rich helium stream, which is passed into the reject-nitrogen stream.

The reflux-exchanger action resembles the upper part of a distillation column but has two distinct advantages over a column:

- The temperature difference between the feed stream and the stream providing refrigeration is small, thus giving high efficiency.

- The exchanger has in effect a large number of partial-condensation stages, so that temperature and composition differences between vapor and liquid are small and separation is effected near to equilibrium conditions.

Capacity control

The turndown requirements for the unit were to be able to run at any capacity between 30 MMscfd and 200 MMscfd and to be able to move between plant capacities at a ramp rate of 2 MMscfd/min.Facilitating this requirement were the following design features:

- Compression. The main compression system consisted of four machines, each having a capacity of 25%-that is, 50 MMscfd-with each motor rated at 4.1 megawatts. These compressors can deliver between 55 and 75 barg, depending on NTS pipeline pressure.

- Molecular sieves. At minimum feed-gas nitrogen content-that is, 8%-all of the reject nitrogen produced by the cold box is required for mol-sieve regeneration.

- Process-control system. Flow rate to the gas-treatment plant is controlled; any change in the required flow is input to the DCS.

The main reason for this approach is the relatively rapid ramp rate and the need to maintain process temperatures and liquid levels. Some controllers use temperature set points cascaded onto flow controllers.

As temperature controllers are normally slow acting, feed-forward control ensured that the temperature controller did not retard the ramp rate.

Construction strategy

The bulk of the equipment arrived at site as preassembled modules. This ensured much of the fabrication work was performed in controlled workshop conditions, thus enhancing quality control.This approach also minimized schedule risk (associated with working in a coastal environment) and maximized the time available at site for completion of civil and building work before onset of mechanical hook-up.

Preassembled units included:

- Methane preseparation column. This column was trayed, insulated, fitted with ladders, platforms, external pipe work, instrumentation, and lighting, and transported to site. With this approach, any high-level work was minimized, and the column in its fully dressed state was complete within days of delivery to site

- Preassembled pipe racks. These racks were fully fabricated, fire proofed, loaded with pipe work, painted, insulated, and tested before shipment to site. Laser alignment, with particular attention to site surveying of the preformed concrete-support piers, ensured hook-up of these units without need for any rework on site and minimum amount of scaffolding.

- Adsorber and suction-drum control and switching valves. These valves were connected complete with all necessary pipe work, instrumentation, insulation, platforms, ladders, and lighting.

- Filters and filtration equipment. This equipment includes associated piping, platforms, ladders, instrumentation, and lighting.

Because of the overall sizes of the heating medium heater, ground flare, and thermal oxidizer, these items were site assembled. They were contracted as turnkey packages from the proprietary equipment suppliers.

The control of site construction work was especially important because the plant location, adjacent the River Dee, is a "site of special scientific interest"; strict environmental conditions controlled all stages of the project including minimization of emissions and site and plant appearance.

Approximately 100,000 man-hr of engineering work and project management were expended on the project in addition to almost 500,000 man-hr in construction and module assembly. The site work force peaked at approximately 300.

The plant was built in full compliance with U.K. Health and Safety Executive Construction and Design Management regulations and has undergone considerable monitoring to ensure these new regulations are adhered to.

In scope, construction work was managed under the U.K. National Agreement for the Engineering Construction Industry, the site being nominated as part of the overall power-plant construction project.

References

- Streich, M., "N2 Removal from Natural Gas," Hydrocarbon Processing, April 1970, p. 86.

- "Ethane and helium recovery," Hydrocarbon Processing, April 1984, p. 66.

- O'Brien, J.V., and Maloney, J.J., "Continuous improvement in nitrogen rejection unit design," Hydrocarbon Engineering, September 1997, p. 68.

- Rathmann, W., and Grimm, P., "Separation of NGL, Nitrogen and Helium from Natural Gases and Associated Gases," Linde Reports on Science and Technology, p. 14, Vol. 34, 1982.

- Boocock, R., and Trautmann, S., "Nitrogen Rejection Units in Natural Gas Processing," Gas Processors Association European Chapter Meeting, London, Sept. 26, 1991.

- Finn, A.J., and Kennett, A.J., "Separation of nitrogen from methane- containing gas streams," U.K. Patent No. 2208699.

- Mayer, M., and Crowe, T., "The North Morecambe Onshore Terminal," Gas Processors Association European Chapter Meeting, London, Sept. 28, 1995.

- Limb, D.I., "Poland's Natural Gas Will Fuel Major Helium Buildup," Chemical Engineering, December 1974.

- Duckett, M., and Ruhemann, M., "Cryogenic Gas Separation," The Chemical Engineer, December 1985, p. 14.

- Finn, A.J., "Enhance Gas Processing with Reflux Heat Exchangers," Chemical Engineering, May 1994, p. 142.

The Authors

Mike Healy is process engineering manager at Costain Oil, Gas & Process Ltd., Manchester, U.K. Previously, he worked for M.W. Kellogg Ltd., London. Healy holds a BS in chemical engineering from Nottingham University and is a fellow of the Institution of Chemical Engineers and a chartered engineer in the U.K.

Adrian Finn is chief process engineer with responsibility for process development at Costain Oil, Gas & Process. He holds a BS Tech in chemical engineering and fuel technology from Sheffield University and an MS from Leeds University. He is a fellow of the Institution of Chemical Engineers and is a chartered engineer in the U.K. and a member of the Gas Processors Association.

Les Halford is operations director at Costain. He has a B.Tech in chemical engineering from Bradford University and an MS in construction management from Cranfield Business School. He is a member of the Institution of Chemical Engineers and is a chartered engineer in the U.K.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.