Rig clubs help alleviate Caspian Sea drilling shortage

Several international consortia in the Caspian Sea have formed rig-sharing groups, providing a means to fulfill production-sharing obligations with a limited number of mobile offshore drilling units (MODUs).

Unfortunately, with only two semisubmersibles, one jack up, and one barge able to meet international drilling standards for safety and efficiency, exploration and production activities may continue at a slow pace. That, in turn, could delay economic pressure for the construction of additional high-capacity pipelines (OGJ, Apr. 19, p. 32).

Fleet update

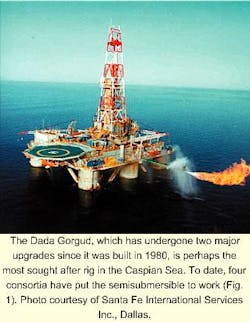

There are only two MODUs capable of drilling in the deep waters of the Caspian Sea-the Dada Gorgud and the Istiglal. Both semisubmersibles, owned by SOCAR and managed by Caspian Drilling Co., a SOCAR and Santa Fe International Services Inc. joint venture, have been upgraded with modern drilling packages, allowing them to drill to 25,000 ft in water depths up to 475 m (1,560 ft) (see Box: Caspian deepwater semisubmersibles).

The Dada Gorgud (Figs. 1), built by Freide & Goldman in Finland and assembled in Astrakhan by Rauma Repola in 1980 (OGJ, May 5, 1997, p. 66), was modernized in 1996 when Azerbaijan International Oil Co. (AIOC) proceeded with its production-sharing agreement (PSA). This vessel remained dedicated to AIOC activities until July 1997, drilling four wells over an 11-month period (Table 1).

Rig Club 1

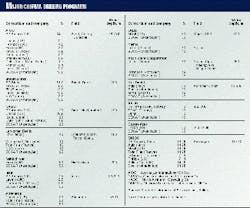

After this program was finished, AIOC, Caspian International Petroleum Co. (CIPCO), North Absheron Operating Co. (NAOC), and BP Shakh Deniz, formed Rig Club 1 to satisfy the need for available drilling units (see box: Major Caspian drilling programs).

This agreement, which began in June 1997, covered the future use of the Dada Gorgud and the Istiglal. To expedite the various work programs in Rig Club 1, the Istiglal (Fig. 3), formerly a Soviet-owned semisubmersible called the Shelf 5, was upgraded in the KMNF Shipyard near Baku and began operations for BP Shakh Deniz last December.1

Built in 1991 and following an extensive upgrade, this MODU now contains more advanced drilling equipment and capabilities than the Dada Gorgud, allowing it to drill through higher-pressure formations and water depths up to 700 m.

Prospects

After CIPCO and NAOC completed their programs in early 1999 (Table 1), the Dada Gorgud was released from the agreement, while the Istiglal continued to work for Club 1 in the Shakh Deniz field. Unfortunately, during the 1998 program, CIPCO drilled three unsuccessful wells in the Karabach field, terminating its operations in early 1999.

On the other hand, AIOC with the Dada Gorgud encountered promising test results in the Guneshli-Chirag-Azeri fields, testing several horizons for hydrocarbons and adding to the success of the Chirag 1 platform, now producing in excess of 100,000 bo/d.

Other consortia have also obtained promising results, which without the rig-sharing concept would not have been possible. For example, NAOC's first of three planned exploration wells in the Ashrafi-Dan Ulduzu contract area successfully tested two zones with the Dada Gorgud in January 1998.

One zone achieved 620,000 cu m/day of gas and 40 tonnes/day of condensate, while the other tested 460 tonnes/day of oil and 36,000 cu m/day of gas (1.3 million cfd).

Club 2

Unfortunately, these two rigs cannot possibly drill enough wells to meet the demands of 14 operating groups. As a result, members have begun to form new clubs depending on new-build construction and refurbishment activities of stacked vessels.

For example, to satisfy drilling requirements in the shallow waters of the Caspian Sea, Elf Aquitaine and Mobil have formed a second club to work their Lenkoran Deniz and Oguz prospects (see box: Major Caspian drilling programs), contracting Sedco Forex to construct and operate a Mod 5 jack up, the Triton 20.

This rig, under construction in Singapore with final assembly slated for the Caspian shipyard facility outside Baku, is due for completion November 2000 and will initially conduct operations in the Oguz field.

Soviet rigs

Other MODUs in the area, which may someday expand the fleet, include three mothballed Soviet semisubmersibles-Shelfs 1, 2, and 3-all of which need substantial upgrades before they can be put to use.

For example, the Shelf 1 is basically in scrap condition while the Shelf 2 has been exposed to fire. A more promising candidate includes the Shelf 7 semisubmersible, built in the early 1990s and owned by Lukoil. Additionally, there are six mothballed jack ups in the Caspian fleet, the Khazars 1-6, none of which may ever see service again.

Finally, the National Iranian Drilling Co. also owns a Friede Goldman-designed L 780 Mod 2 built in Iran in 1995. Unfortunately, this rig suffered an accident 6 months ago, seriously damaging its legs.

North Caspian

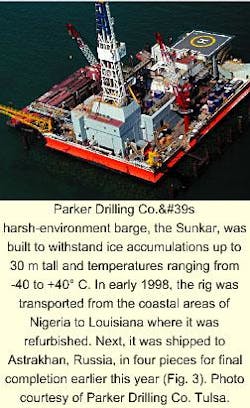

The newest rig in the Caspian Sea, Parker Drilling Co.'s, Sunkar (Fig. 3), spudded its first well for Offshore Kazakhstan International Operating Co. (OKIOC) Aug. 14.

Located in the Kashagan East prospect about 75 km south of Atyrau, Kazakhstan (OGJ, July 26, 1999, p. 37), the rig will be used to explore reservoirs and structures thought to be similar to those found in western Kazakhstan's Tengiz field.

This refurbished, harsh-environment barge, designed for shallow but highly variable weather conditions in the Northern Caspian Sea, is built for zero discharge.

Also operating in the Russian sector of the North Sea is a BMC 150 jack up, owned by Lukoil.

Multinational communications

In order to meet commitments and expedite drilling operations for more than 25 multinational companies, hailing from 13 countries, the rig clubs must overcome communication and cultural barriers. For example, out of the 315 Caspian Drilling Co. employees, 252 are Azeri, 19 are Americans, 9 are Australians, and the rest are Canadian, continental Europeans, and New Zealanders.

Not only must these employees work with each other (Fig. 4), but they must also interact with operating personnel from France, Italy, Japan, and other countries.

"One of the early success stories is Nuredin Kerimov, [an Azeri] who now works as a supervisor for BP Amoco on the Bruce platform in the North Sea," said Paul Bruton, deepwater project manager for Santa Fe.

To expedite communications, English has been established as the language for all drilling operations. "During the initial 12-month refurbishment of the Dada Gorgud," Bruton said, "30 min English classes were held for every crew."

But to form even closer cultural ties with the Azeri counterparts, the expatriates have also been schooled in Russian and Azeri. "Several of the in-house training programs have been followed by barbecues and social gatherings while many of the expat staff members have been invited to weddings," he said.

Recognizing, however, that a second language takes time to master, the Caspian Drilling Co. conducts all personnel inductions, safety meetings, and risk assessments with the assistance of interpreters, while all training materials are translated into the local language.

Additionally, internationally recognized crane signals have been adopted for lift operations while warning signs positioned around the Dada Gorgud and Istiglal are either placed in pictorial format or dual languages.

Thus, as new rig clubs come into being, not only will capable rigs be required to exploit the vast reserves of the Caspian Sea, but each company and contractor must have in place a multinational workforce that is in tune with one another.

Reference

- Offshore Magazine, January 1999, p. 134.