Model simplifies filter cake lift-off pressure determination

A simple, effective model is available for estimating filter cake lift-off pressure, an important factor affecting the productivity of horizontal wells.

Filter-cake cleanup during flow back is crucial because complete cake removal increases flow area and minimizes skin pressure drops. Residual filter cakes can severely impair the productivity of gravel packs, screens, and liners and result in high-velocity flow regimes in certain parts of the formation. These regimes could induce borehole weakening, sand production, and gas or water coning.1

The flow initiation pressure is directly correlated with the extent of solids invasion. It represents mostly internal core cleanup rather than actual filter-cake removal.

The new model calculates the flow initiation pressure (DPfi), agrees well with experimental results, and quantifies for the first time the dependence of flow initiation pressure on the rock permeability, flow rate, depth of solids invasion (internal formation damage), and filter-cake rheological properties.Drilling and completion fluids typically are designed to have minimal fluid loss and solids invasion. It is equally important, however, to design fluids that clean up easily during flow back. Muds with low solids invasion and appropriate rheology are needed to minimize flow initiation pressures.

Filter cakes

Drill-in and completion fluids are usually designed to form an external filter cake that minimizes fluid leak-off to the formation. In general, low solids invasion and filtrate loss results in less formation damage.

Standard fluid design, however, does not usually consider another important characteristic of cake-building solids, such as the effectiveness of filter-cake removal prior to or while producing a well.

It is often observed that a very small fraction of the filter cake is removed, while most of the formation still remains covered by the cake.2 This condition results in only small portions of the flow area contributing to hydrocarbon inflow.

Once a small fraction of the formation is open to flow, there may be insufficient pressure gradient to remove the filter cake from other parts of the formation face. Several laboratory studies have been conducted on removing cake from core surfaces.1-7

The pressure required to initiate flow after filter-cake buildup is the flow initiation pressure. Bailey correlated the flow initiation pressure with the yield stress of the external cake measured by a hole-punch method.3 Flow initiation pressure depends not only on cake properties but also varies systematically with core permeability and flow-back velocity.4

Ryan reported that total cake removal is not required for oil flow.5 This study, with some water-based muds, suggested that 100% return permeability was achieved even with visible cake remaining across the entire core face.

It further concluded that oil-based muds clean up better than water-based muds. Breakthrough pressure (similar to a flow initiation pressure) and permanent damage levels were found to be less for oil-based muds.

Cake removal with breakers, such as 15% hydrochloric acid or an oxidative solution, results only in partial cake removal and marginally less formation damage. This is because the breaker usually has inadequate contact time with the cake, especially for long producing intervals.

In many instances, the breaker is partially spent by interactions with noncake materials or lost to nontarget zones. Even if the breaker is placed within the target zone, wormhole formation can leave large sections of unbroken cake.

Internal breakers such as enzyme breaker systems for filter-cake removal have been developed.6 These are designed to target specific polymers in a drilling mud. A 15% hydrochloric acid following the enzyme system is often required for effective cake removal. Placement problems, however, can be expected.

Certain internal breaker systems can also increase flow initiation pressure and heighten formation damage.6

Experimental observations

An earlier study presented extensive filter cake lift-off test results, which clearly showed that the flow initiation pressure, DPfi, obtained for sized-calcium carbonate (CaCO3) and sized-salt filter cakes is affected by rock permeability, filtration pressure, flow-back rate, and mud type.4Complete filter-cake removal only occurred in core samples with the highest return permeability. Severely damaged rocks (low return permeabilities) did not show any evidence of cake removal. This finding suggests that cake removal may be related to the extent of solids invasion causing better filter-cake adhesion, and therefore, less cake removal during flow back.

Solids invasion

Lift-off tests were conducted for investigating how much the internal damage contributes to the overall differential pressure during flow back. In these tests, the external filter cakes were completely removed before flow back.

Figs. 2a, b, and c show the results of three tests that used a sized-CaCO3 mud on Texas Cream limestone and Berea sandstone, and a bentonite mud on a Berea sandstone core sample.

After 16 hr, the filter cake was removed or mechanically scraped off the core surface. A thin layer of filter cake (residue) remained on the core face because chemicals or solvents were not used.

The core samples with no filter cake were then reinstalled into the filter cell and a flow-back experiment was conducted with Escaid (mineral oil) at 5 ml/min. The differential pressure profiles recorded during flow back reflect the pressure drop due to fluid flow through the damaged core samples with no filter cake sitting on top of the samples.

Comparisons were then made with similar lift-off tests in which filter cakes were not physically removed. Fig. 2a shows the results for a Texas limestone core sample (with sized-CaCO3 mud).

The following observations can be made:

- The pressure profile for both tests is very similar. The slight differences in actual values are within experimental reproducibility and could be due to small differences in core permeabilities. After starting flow back, maximum pressure is reached within 2-3 min, followed by a more gradual decrease in pressure. The pressure then continues, decreasing to reach the final differential pressure across the core sample.

- The calculated flow initiation pressure for the test in which the filter cake was initially removed is 45.7 psi, which is comparable to the 44.0 psi for the test in which the filter cake was not removed.

- High return permeability ratios were observed for both tests (95-98%).

Fig. 2b shows the cake lift-off test on the Berea sandstone core samples and sized-CaCO3 mud under the same test conditions. One curve is for the test in which the filter cake was initially removed before flow back. Again, the same observations as for Texas limestone were noted.

Briefly, the flow-back pressure profiles are very similar, the flow initiation pressure is comparable (5.3 psi for flow back with no filter cake compared with 3.3 psi with filter cake), and the return permeability ratios are also the same (18% compared to 16%). Similar observations are made for the test using a bentonite mud system on a Berea sandstone core sample (Fig. 2c).

These results indicate that peak pressure during flow back is mainly due to cleanup of internal damage within the core samples. This is contrary to most intuitive explanations provided, to date, that associate peak pressure with detachment or removal of the external cake from the core surfaces.

High pressure gradients are required to dislodge and remove the particles forming the internal filter cake. Depending on the extent of solids invasion, the fluid injected during flow back may or may not carry the particles out of the core sample, thus enabling a regain in permeability.

These tests and earlier tests show that the flow initiation pressures can be correlated with the return permeability.4 This is because they are both directly related to the extent of solids invasion.

The extent of solids invasion, which is also directly related to the internal formation damage, therefore, must be related to the flow initiation pressures needed for filter-cake removal. This relationship is quantified in the model that has been developed.

Cake lift-off model

The model is concerned with fluid flow back through a core after filtration is complete.

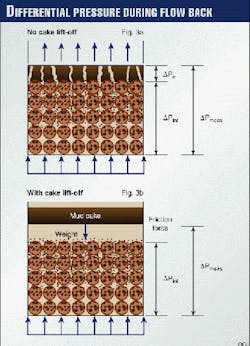

For a case without cake lift-off, the measured pressure drop across the core and the external cake (Fig. 3) can be written as Equation 1 (see equation box). Equation 2 is for a case with cake lift-off.

The second two terms on the right-hand side of Equation 2 represent the weight of the cake and wall friction as the injected fluid lifts the cake. It is easy to show that these terms are small compared to the differential pressure across the core, DPint. It follows that the pressure drop across the filter cake during flow back, DPc, is small as well because the conditions for cake lift-off can be written as Equation 3.This implies that DPc is less than the two terms on the right-hand side of Equation 2 in cases where there is no cake lift-off.Because DPint dominates the measured DP, the flow initiation pressure is a measure of the pressure needed to remove the invaded solids from the pore throats.Modeling this process in a simplistic fashion, one can write an expression for the pressure gradient needed to flow a Bingham plastic fluid from a cylindrical pore of diameter, dp. Integrating the equation over the depth of solids invasion, Xd, the flow initiation pressure can be written as Equation 4 (in field units).

For simplicity, if one assumes that the terms in brackets do not change with distance into the core, the equation can be written as Equation 5, which consistently explains all the experimental observations.

Experimental results comparison

The effect of core permeability on flow initiation pressure (Fig. 1a) is consistent with Equation 5. As the permeability increases, the flow initiation pressure decreases to a point due to an increase in the pore size, dp. For very large permeability cores, the invasion depth, Xd, increases, offsetting the effect of an increased dp. This results in a minimum observed DPfi.As seen in Fig. 1b, DPfi increases linearly with flow-back velocity. This also is consistent with the model. The velocity dependence of the flow initiation pressure is a significant function of the rheological model chosen to describe the internal filter cake.For a Bingham plastic model, DPfi is proportional to the yield stress of the internal cake, which is related to the yield stress of the external cake, as suggested by Bailey.3Higher overbalance pressure during static filtration increases solids invasion and internal formation damage because of the greater force pushing particles into the pore spaces in the core.

The flow initiation pressure, therefore, is expected to be higher. The high overbalance pressure, however, could also expedite filter-cake buildup thus reducing solids invasion during spurt loss.

This competing effect will result in less severe internal damage and a lower flow initiation pressure.

Most of our experiments suggest that high overbalance pressures during filtration increase the flow initiation pressure. It should be noted, however, that the differences in the flow initiation pressure are small.

This suggests that high overbalance pressure does increase internal formation damage (lower return permeability ratio).4 This observation also supports our conceptual model, which suggests that more solids invasion causes higher flow initiation pressures.

The above model was derived assuming that the internal cake behaves as a Bingham plastic fluid, but the model could be extended to more complex cake rheologies, should that be necessary. A more urgent need, however, is to devise methods to study the rheological properties of the invaded solids and the extent of invasion, for example invaded solids concentration vs. depth into the core.

For engineering purposes, Equation 5 provides a practical method to estimate filter cake flow initiation pressure and its variation with core and mud properties. A more detailed discussion of coupling Equation 4 with the extent of solids invasion occurs elsewhere.7

Sample calculations

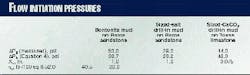

Table 1 summarizes examples of the flow initiation pressure calculated with Equation 5 and compared with measured values from filter cake lift-off tests.6

The model calculates the DPfi for flow back of the bentonite filter cake on Berea sandstone core to be 36.7 psi, compared to 50 psi from the experiment. This case assumes a 1.0 in. solids invasion depth and a 52 lbf/100 sq ft yield point.3 The flow-back pressure for the sized-salt filter cake on Berea sandstone core was calculated to be 29.2 psi, compared with 29 psi measured in the experiment.Xd in this case was also assumed to be 1.0 in. (which represents a severely damaged condition after flow back for all Berea sandstone cores) with a yield point of 40.5 lbf/100 sq ft.

Lastly, the model calculated a 48.9 psi flow initiation pressure required to flow back a sized-CaCO3 filter cake on a Texas Cream limestone core. This compares with the 44 psi measured in the experiments. The calculated solids invasion depth of 0.075 in. is consistent with the high return permeability of the Texas limestone cores. The estimated yield point is 30 lbf/100 sq ft.

These three cases show that the flow initiation pressures calculated by the model are comparable to measured pressures in the filter cake lift-off tests. The estimated DPfi depends greatly on the solids invasion depth, Xd, and the yield point of the internal filter cake, ty.Proper measurement techniques must be used to determine accurately the depth of solids invasion into a core sample and the yield point of the filter cake under the test conditions (filtration pressure and temperature).

Acknowledgments

The authors would like to thank the sponsors of the Improved Well Performance Research Program at the University of Texas at Austin.

References

- Alfenore, J., Longeron, D., and Saintpere, S., "What really Matters In our Quest of Minimizing Formation Damage In Open Hole Horizontal Wells," Paper No. SPE54731, European Formation Damage Conference, The Hague, May 31-June 1, 1999.

- Browne, S.V., and Smith, B.P., "Mudcake Cleanup To Enhance Productivity of High-Angle Wells," Paper No. SPE27350, SPE International Symposium on Formation Damage Control, Lafayette, La., Feb. 7-10, 1994.

- Bailey, L., Meeten, G., Way, P., and L'Alloret, F., "Filtercake Integrity and Reservoir Damage," Paper No. SPE39429, SPE International Symposium on Formation Damage Control, Lafayette, La., Feb. 18-19, 1998.

- Zain, Z.M., and Sharma, M.M., "Cleanup of Wall-Building Filter Cakes," Paper No. SPE56635, SPE Annual Technical Conference and Exhibition, Houston, Oct. 3-6, 1999.

- Ryan, D.F., Browne, S.V., and Burnham, M.P., "Mud Clean-Up in Horizontal Wells, A Major Industry Study," Paper No. SPE30528, SPE Annual Technical Conference and Exhibition, Dallas, Oct. 22-25, 1995.

- Beall, B.B., Tjon-Joe-Pin, R., and Brannon, H.D., "Field Experience Validates Effectiveness of Drill-In Fluid Cleanup System," Paper No. SPE38570, SPE Annual Technical Conference and Exhibition, San Antonio, Oct. 5-8, 1997.

- Zain, Z.M., and Sharma, M.M., "Mechanisms of Mud Cake Removal During Flow Back," to be presented at the SPE International Symposium on Formation Damage Control, Lafayette, La., Feb. 23-23, 2000.

The Authors

Mukul M. Sharma is a professor of petroleum engineering at the University of Texas at Austin. His current research interests include petrophysics and formation damage. Sharma has a bachelor of technology in chemical engineering from the Indian Institute of Technology and an MS and PhD in chemical and petroleum engineering from the University of Southern California.