Tuscaloosa marine shale oil play seems ready for liftoff in Mississippi

As the oil and gas industry tries to regain its composure from the latest pricing crisis, many will begin to look for drilling opportunities. Mississippi has a share in what has been reported as a 7 billion bbl recoverable oil play.

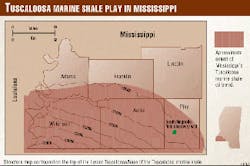

The risk in this play is not in finding oil-the risk is in producing commercial quantities by applying the latest drilling and completion technologies. Wilkinson and Amite counties and part of Pike County appear at this time to hold the most promise in this play in Mississippi (Fig. 1).

For many years explorers and drillers have come to expect gas kicks and oil on the pits when they drilled through Tuscaloosa marine shale on the way to Lower Tuscaloosa sands. No doubt, many of those folks have dreamed of developing some technique to get that oil out of the shale.

Exploration history

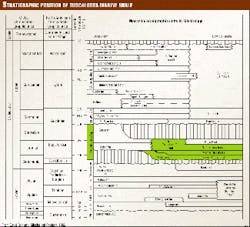

The presence of oil in the Tuscaloosa marine shale has been common knowledge among those who have drilled Lower Tuscaloosa prospects in southwestern Mississippi and the Florida Parishes of Louisiana (Fig. 2). A 1997 publication, BRI Bulletin, published by Louisiana State University Basin Research Institute, presents some history and a general outline of the potential play. The authors also estimate the recoverable reserves for the play in Mississippi and Louisiana at a combined 7 billion bbl of oil.

Mississippi background

Awareness at the Mississippi Office of Geology of the play's potential first came in July 1992 in discussions with a major oil company in Lafayette about its plans to drill a horizontal marine shale well.

The author was involved in this proposed Wilkinson County well because the state had an interest in the well to be re-entered. At that time, discussions centered on the company's regional study of the play with interesting isopachs of three units or facies of the marine shale, the high resistivity lower section being the zone of interest. For whatever reasons, the company decided not to pursue the $3 million+ AFEd marine shale horizontal experiment.

The next exposure came through the Mississippi Department of Economic and Community Development (MDECD). A Natchez independent, Monta Currie Jr., approached the department while trying to secure funding to get a horizontal well drilled in the marine shale. At a meeting on July 6, 1995, our role was to listen to the presentation and advise MDECD on the geologic merits. Currie showed his trend map, which looked like what had been described by the Lafayette major several years earlier.

Our assessment was that the project was interesting and needed to be pursued in spite of the high risk. That "high risk" didn't fit the niche of funds available, so that meeting didn't advance the drilling effort.

BRI's 1997 study on the play was the first public document to our knowledge and remains a fine starting place for anyone interested in the marine shale's oil potential. An excerpt from that article was published in these pages (OGJ, Dec. 29, 1997, p. 91).

Thus, it turned out that our exposure to the play idea had run from 1992 through 1997, but no one tested the hypothesis that horizontal drilling could make this known resource commercial.

Risk-taker needed

What was needed was someone with the dollars and the gutsy, risk-taking attitude that seemed to have characterized so many of the early industry wildcatters.

That needed character profile may have come forward in one Randy Braswell. Braswell began his risk-taking when he started buying and selling timber in Amite County at age 16. He then found himself with land after trees were harvested, so he used the sand and gravel resources to build locations for oil and gas wells.

Then he was approached to lease some of his minerals, which resulted in his entering the oil and gas business. This success led to his participation in wells as mineral owner and working interest investor. Braswell developed an early appreciation for utilizing all of the resource at hand, a trait he carried into the first successful horizontal well drilled in the Tuscaloosa marine shale trend.

Discovery well

The first successful horizontal drilled well in the trend began like most other wells drilled to depth in this area as a vertical Lower Tuscaloosa prospect. With the consulting services of Wayne Upchurch on geology and geophysics and engineering by David Craft, Braswell drilled the prospect straight up.

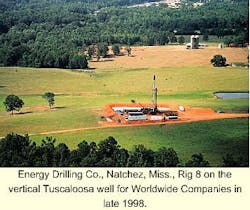

The well was permitted as the Worldwide Companies 1 Braswell 24-12, in 24-2n-7e, Pike County, Miss. The well was spudded on June 15, 1998, drilled to 11,414 ft, and logged. The decision to run pipe was influenced by the recognition that the marine shale was a backup zone of interest. Upchurch, Craft, and William Watkins, who is a local independent and friend of Braswell, had encouraged Braswell to seriously consider the possibilities in the marine shale.

The decision was made to set 51/2 in. casing to 11,391 ft. The Lower Tuscaloosa sand was evaluated, and the completion effort was shifted to the Tuscaloosa marine shale.

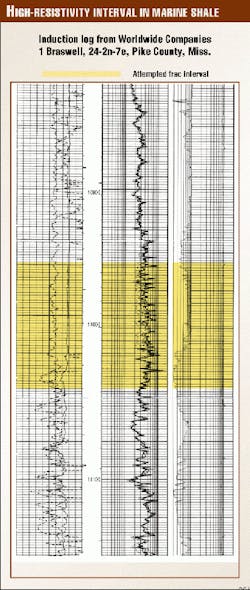

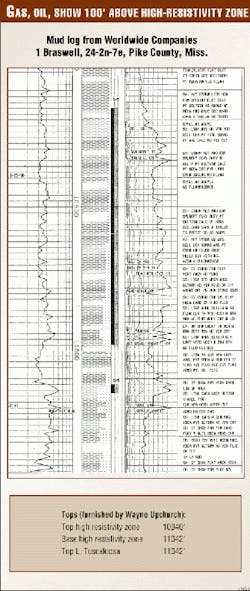

The first effort was to attempt a frac in the high-resistivity zone of the marine shale (Fig. 3). The mud log had picked up gas shows nearly 100 ft above the high-resistivity zone, and the predictable oil on the pits came at the top of the high resistivity, 10,940-50 ft (Fig. 4). The attempted frac was performed through perforations at 10,958-11,058 ft.

The well was tested after the frac and showed some encouraging signs. When allowed to build up pressure during shut in, it would come back with around 107 bbl of oil and no water in 13 hr; 40 bbl might come in the first hour. The official completion for this discovery well for Magnolia South field was reported as flowing 102 bo/d, 50 Mcfd, on a 12/64 in. choke, FTP 283 psi, GOR 490.

Drilling, completion

Although there was no prolonged test, Upchurch felt the well capable of sustaining 60-70 b/d. Braswell had higher hopes than a 60 b/d well. He hired horizontal drilling experts, listened to their suggestions, and then made up his mind to attempt to be the first to successfully drill a horizontal well in the marine shale.

Braswell was aware that others in Mississippi had attempted vertical completions and some had tried building angle in the marine shale, including majors, but their efforts had failed. He thought about taking on partners, perhaps government or industry, but that would complicate decisionmaking, so he chose to make this financial journey on his own.

Having hired a team of consultants, Braswell hosted the team coordination meetings. There he followed his style of listening to his experts' opinions and then himself deciding the course of action. The plan was to drill underbalanced using oil-based mud. As one might expect, considerable attention was paid to the makeup of the marine shale clays and how they might react to the mud. The plan was for two laterals, one 2,000-footer to the north and one 2,000-footer to the south. Gardes Directional Drilling, Lafayette, La., would handle the horizontal drilling.

The first lateral was in trouble from the beginning. It was supposed to head north, but an incorrectly set whipstock sent it to the west. The attempt to correct the mistake by turning north created problems too troublesome to deal with, so a slotted liner was set in this attempted lateral of 260 ft. The next lateral had fewer directional problems and resulted in a successful 1,200-ft true lateral in the high-resistivity zone of the Tuscaloosa marine shale.

Braswell had succeeded as far as the drilling challenge was concerned, and now it was time to produce.

Production impediments

After setting a slotted liner in the southern lateral, production testing was attempted. Braswell's crew said the well would flow as much as 2 bbl/min of 39° gravity oil on an open choke, and then something would block the flow and it would decline to 2 bbl/hr.

This first production problem seemed to be associated with the formation reaction to the drilling mud, which resulted in a thick emulsion that would cause blockages throughout the production string. When the blockages were cleared, the flowing oil would again come on strong, and then the blocking would recur.

The plan was to run in using a coiled tubing unit and spot a treatment designed to help clean the hole. The coiled tubing got hung up. A tubing cutter also hung up. Then a snubbing unit was moved in to shove all of the junk in the hole to the end of the lateral. With the junk out of the way, periodic production testing resumed.

At this point, a new problem occurred. It now appeared that pieces of siltstone, some 1/2 in. in diameter, were entering the slotted liner and forming blockages to production flow. When the production string was clear, the well would flow 150-200 bo/d on an 8/64 in. choke without losing pressure.

The well flowed for 13 days at one point. During that time, the siltstone bridging would occur and had to be cleared, but 13 days was the longest running production test period so far.

As a part of his evaluation effort, Braswell had a swabbing unit on the well and played with the fluid levels. If one takes too much hydrostatic pressure off the formation, the fluid entry rate drops dramatically. Once the critical fluid level is re-established, the rate of fluid entry from the formation will swab much better than 200 bo/d. Between his own experience and the opinion of several of the consultants, Braswell is convinced the well can do much better than the 200 bo/d.

The future

So with this well we have taken a giant step toward the possible establishment of a new technology-driven play.

Braswell, Upchurch, and Watkins learned a lot about horizontal drilling in the marine shale. The next well that is being planned will greatly benefit from that experience.

When one reviews the LSU study, adds in the results of Worldwide Companies 1 Braswell, and considers the relatively shallow depths in Mississippi's part of the play, it doesn't seem unreasonable that technology might have opened the door for widespread development of a known resource.

As Upchurch put it, if we reach the point that the marine shale is a widely commercial producer, then every wildcat drilled for Lower Tuscaloosa and deeper in this area can be drilled knowing there is marine shale production behind pipe. That kind of situation could lend itself to 3D seismic programs that would result in a play that incorporates the best science this part of Mississippi has seen.

Other marine shale wells have been permitted, and several drilling deals are being marketed. The play seems set for liftoff.

Acknowledgment

Thanks to Steve Champlin and Brenda Cook for help in preparing this article.

The Author

Jack Moody is director of the Energy & Coastal Division of the Mississippi Office of Geology. Before joining the office in November 1998, he spent 17 years in industry as an exploration manager and-or geologist. He received a BS degree in geology from East Carolina University and then spent 2 years in graduate studies in geology at Louisiana State University.