Field tests illustrate multiphase meter potential

Field tests in Colombia illustrate the potential of multiphase meters to save significant oil field capital and operating costs.

For the past 10 years, the oil and gas industry has sought cost-effective and accurate alternatives to traditional test-separation techniques. The ability to identify changes in the relative proportions and flow rates of oil, gas, and water in a production well has a clear economic impact on the continued development of a particular reservoir.

The process of gathering the information, however, can also be costly.

Earlier in 1999, field testing was completed with a new multiphase-flow metering system in BP Amoco Exploration Colombia Ltd.'s operated Santiago de Las Atalayas, Tauramena, and Rio Chitamena Association contract areas.

This meter was developed in the U.K. by ISA Controls Ltd. under license from BP Exploration & Operating Co. Ltd.

Multiphase metering

The traditional method of multiphase metering has been with test separation. Conventional test separation may involve the temporary diversion of production through a test separator that measures the individual oil, water, and gas components.

Test separation is expensive, with large capital investment in bulky equipment, and may involve restrictions to production for the duration of a test. Operational costs can be high, depending on location and accessibility of the equipment.

In the last few years, several multiphase metering devices have come to the market. Multiphase metering is a technology that offers many advantages for well production and reservoir management. Depending on the technology selected, they may provide much more accurate and consistent well test data than are possible to obtain with test separation.

Because multiphase meters can be used for continuous in-line testing as well as at a temporary installation, the well test data can be obtained either continuously or at frequent intervals with fewer personnel than required for test-separator operations.

Multiphase meters also offer substantial savings in capital investment because they allow the operator to eliminate test separation from new projects, including expensive offshore test lines. Operators also may be able to redeploy existing test separators to other duties such as well clean-up.

Typically, the majority of multiphase meters have fallen into the following two categories:

- Partial separation-type units, which seek to separate the gas from the multiphase fluids to reduce or eliminate slip

- Meters that use flow modeling or other mathematical techniques to simulate or characterize the phase fractions and interphase slip in the multiphase fluids.

The ISA multiphase meter does not rely on either of these techniques. Instead, the meter uses classical metering technology based on the positive displacement. Fluid densities and the water cuts are measured by gamma ray densitometers, using the principle of nucleonic gamma-ray attenuation.

ISA's meter

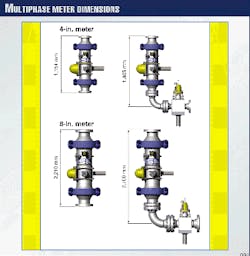

ISA's patented "Multistream" meter (Fig. 1) incorporates twin meshing helical rotors which are designed to turn at very low flows, and each rotation delivers a package of multiphase fluids through the meter body.

The fluids are constrained within a narrow spatial zone by the geometry of the rotors so that the bulk velocity of each of the phase fractions is the same as the rotation speed. This prevents slip and removes the need for the characterization of well fluids using slip models or other mathematical techniques.

Discrete fluid packages are measured at the center point by a gamma ray densitometer. Measurements are taken within a narrow temporal zone, every 0.1 sec, enabling good average density readings.

Together with pressure and temperature readings, which are obtained from standard field-mounted instruments, the meter can thus measure the mass flow rate and gas and liquid fractions.

The meter is mounted vertically in the flow line (Fig. 2). Flow enters from above and strikes a deflection plate that has the twin functions of:

- Reducing the energy of transient forces generated in multiphase flow.

- Deflecting the flow tangentially onto the inclined contours of the rotors.

All signals produced by the metering process are sent by cable to a data-acquisition system in a safe area. Systems are also available that allow the user to download data to a remote personal computer if desired, for example, on unmanned platforms.

The data-acquisition system will accept inputs from the meter and provide oil and gas flow rates, together with line pressures and temperatures. Depending on user requirements, the data-acquisition system can be programmed with industry standard or field-specific equations of state that convert actual to standard conditions.

A well test report, from multiphase meter data, can normally be generated within 60 min after starting a test. This compares to the 8 hr typically required for test reports from a test separator operations.

The characteristic "K" factor similar to single-phase meters is obtained by a one-time calibration of the multiphase meter against a turbine meter in the factory. The turbine meter is in turn calibrated annually to Namas (National Accreditation of Measurement and Sampling) standards, so that the key volumetric flow-rate element of the data is traceable to a national standard.

The mobile version of the meter is installed in a skid frame that is mounted to a transportation base. This includes bypass valves and flexible connections so that a meter can be moved from well to well.

During transport, the meter lies in the horizontal position on the truck. But at the well pad, it is moved on a hinge into the vertical operating position.

Colombia tests

The principal objectives of the multiphase meter tests in the Cusiana and Cupiagua fields were to:

- Reduce the relatively expensive well-test costs.

- Reduce the period between well tests by obtaining more well-test data.

- Reduce or eliminate deferred production costs normally associated with test separator pressure drops.

Over 14 months, 57 well tests on 16 different wells were carried out in the Cusiana oil and Cupiagua gas condensate fields in the Casanare Province.

Cusiana is on relatively flat terrain near a river plain at the foot of the Cordillera Mountains. Cupiagua is in more mountainous territory, but in both cases, the fields have relatively poor roads. In addition, frequent storms in the rainy season often make transportation of heavy equipment, such as test separators, difficult.

Cusiana typically produces a 35° API gravity oil; whereas Cupiagua produces a 41° API gravity gas condensate that is prone to form paraffin deposits. The wells tested have a range of 75-96% gas volume fraction (GVF), corresponding to a 1,540-9,600 cu m/cu m GOR.

Operating with a GVF greater than 80% is one of the most difficult factors for multiphase metering. During the tests, operating pressure ranged from 35 to 92 bar (507-1,334 psi).

The Casanare fields require a minimum of one test/well/month for effective reservoir management and allocation purposes. Conventional well testing with a test separator requires the transportation of large pieces of equipment from well pad to well pad.

Depending upon the potential of a well, this may involve two or three test separators being used in parallel, requiring five heavy trucks to transport this equipment over difficult terrain.

The test-separator installations require temporary 3 or 4-in. connections that can take up to 6 hr to complete. This temporary pipe-work also must be tested hydraulically for leaks, adding further time for the set-up process.

Once the well is flowing through the separator, stabilization of separator levels can take 3 hr, followed by a minimum test period of 8 hr. After the well test is completed, the pressure vessel must undergo a period of blow down, followed by decommissioning of the separator and equipment.

Overall, operating continuously for 24 hr, BP performs three well tests per test team in 1 week on average.

Testing program

Testing at Cusiana/Cupiagua started in November 1997 and continued through the first quarter of 1999. During this period, over 57 well tests were conducted with reference separators operating in series with an 8-in. metering system.

Two commercially available portable test separators and a permanently installed separator at the Cusiana central processing facility provided the reference points.

Both the meter and the reference separators reported oil and gas flows at standard conditions. Field-specific equations supplied by BP Amoco for oil shrinkage and gas expansion were used to convert the measurements to standard conditions.

All reference separators used the identical oil shrinkage equation. For gas expansion, however, an AGA 3 equation was generally used for all the reference test separators.

BP Amoco engineers were responsible for the vast majority of data collection and collation. Local personnel carried out field testing work after 2 weeks' training from ISA in the U.K. and further training on site in Cusiana.

The original operating team had no experience of well testing before its involvement with the meter.

A replacement team, recruited at short notice and with well-testing experience, was trained in 4 days to use the equipment, including the data-acquisition system.

Throughout the test process, the robustness of the original calibration was demonstrated by consistent results as the meter was moved from one well to another.

Calibration on well-specific fluids was unnecessary at any point during the trials, and no adjustments to algorithms were carried out at any point in the trials.

No meter drift was detected during the operating period.

Currently, the wells in the Cusiana and Cupiagua fields produce with a low water cut, and therefore the methodology adopted to determine water cut involved sampling and centrifuging. Water cut, however, is expected to become more of an issue in the future.

Test results

BP Amoco carried out intermittent testing over 14 months and concluded with an endurance and robustness test of the meter that involved continuously operating the meter for more than 1,000 hr at high flow rates.

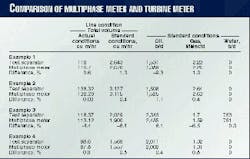

At these high flow rates, the meter consistently measured oil and gas flow rates on 16 different wells in two fields to within &#tilde;5% of three different test separator reference systems. Repeatability was well within plu or minus 3%. Table 1 tabulates some of the test results.

Casanare well tests typically were over an 8-hr period, reported at 30 min intervals. Tests on a number of wells, whose flow was regular and without heavy slugs, demonstrated that the multiphase meter could reduce the test period to 1 hr.

With the meter, well test reports were printed out within 30 min after a test was concluded.

Significant cost savings on well testing with the multiphase meter were demonstrated in terms of:

- Less equipment moved from well pad to well pad

- Less manpower for installation and operation

- Shorter well test period

- Less pressure drop over the testing system, thus preventing production from being deferred.

The testing proved that multiphase meters were practical for replacing test separators in both fixed and mobile applications. As a result, the meters are now being used in the Casanare operations.

Also, as the Cusiana wells begin to cut water, ISA has developed and tested a full-flow automated water-cut meter. ISA's "Gammastream" meter can be bolted on downstream of the multiphase meter as an integral part of the metering system or used separately as a standalone, water-cut meter.

The dual-energy, gamma ray densitometer design allows accurate water-cut measurements. The instrument also is not sensitive to changes in oil continuous or water continuous regimes or changes in GVF.

At remote well pads, the metering system, because of its low power requirements of as little as 50 w, can be powered by a solar array. n

The Authors

Ken Gibson is the engineering director of ISA Controls Ltd., Durham, U.K. During the past 4 years he has lead a team of engineers involved in the development of meters for measuring the flow of two and three-phase multiphase fluid. Gibson is a chartered mechanical engineer in the U.K.

Juan Carlos Agudelo V. is currently in charge of well test engineering and operations at BP Amoco's Cusiana and Cupiagua fields in Colombia. He has 8 years' of experience with several companies in production-facility operations and chemical treatment design.

Agudelo has a petroleum engineering degree from the Universidad Nacional de Colombia, Medellín.