Low permeability filter cake limits damage from high-pH drilling fluids

Zhijun Wu, Younguan Hu

Southwest Petroleum Institute

Nanchong, China

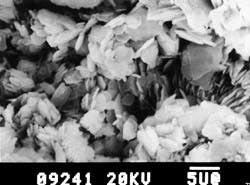

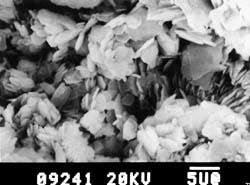

Scanning electron microscope photograph (left-undamaged; right-damaged) shows the damage to the clay structure in the reservoir cores after invasion by high-pH drilling fluid filtrate (Fig. 1).Changing the particle size distribution in high-pH drilling fluids and perforating underbalanced helped protect sensitive reservoirs from formation damage.

In several wells drilled in a carboniferous reservoir system in China, invasion of the high-pH filtrate from the drilling and workover fluids seriously damaged the formation. An in-depth reservoir study determined the cause of the formation damage and led to the development of new field procedures to prevent damage in future wells.

Many drilling and workover fluids used in the Xinjiang field in China are highly alkaline. After these alkaline fluids invade the formation, damage may occur in two ways. First, the alkaline fluid can destroy the structures of the clay minerals and siliceous cement, forming a large amount of fine particles which plug pore throats. Second, the hydroxide ions react with cations in the formation and form insoluble precipitates, which also plug pore throats.

A high-pH well control fluid was used in the Xinjiang oil field for several workovers. After a large quantity of the well control fluid invaded the reservoir, the skin factors of these wells increased tremendously, and the production decreased dramatically. Subsequent lab analysis revealed that the high pH of the workover fluid caused the damage.

The Dong He-1 well was the first well drilled in the Dong He structure in the Xinjiang field, and its objective was a carboniferous formation. Three oil-producing reservoirs were discovered between 5,726 m and 5,746 m.

Drill stem tests on this well showed an oil production rate of 237 cu m/day and a skin factor of 0.21. Production casing was run and cemented, and the well was subsequently perforated.

About 70 cu m of completion fluids leaked into the formation during these operations. The NaHCO3-based completion fluid had a density of 1.17 g/cc, 2.56 million mg/l. salinity, and a pH of 12-13. Following well completion, the well only produced 27 cu m/day of oil, and the skin factor increased to 12.64. The reservoir suffered extensive damage.

Experimental analysis

The first part of studying the extent of reservoir damage involved deterring the basic reservoir characteristics. The reservoir sensitivity to various fluids was measured to help determine what caused the formation damage and also to help develop procedures to protect the formation from further damage.

The reservoir rock contains white, fine quartz sands. The mineralogical composition consists of 80-85% quartz, 1-5% feldspar, 1-8% detritus, 1-2.5% calcite, and 4-8% clay (size smaller than 4 m. Calcite and clay are the cementitious materials in this reservoir rock. The particle diameters of the clast mostly range 0.1-0.4 mm and have a medium roundness. The clay minerals were analyzed by X-ray diffraction. Kaolinite and illite are the main components (Table 1 [24439 bytes]).

The reservoir has good physical properties, with 15-23.7% porosity and permeability reaching several hundred millidarcies.

The flow test program of sandstone reservoir sensitivity was performed to evaluate the velocity, pH, and salinity effects of the drilling and completion fluid on the reservoir.

When fluid flows with high velocity through a reservoir, particles inside the reservoir may migrate and plug pore throats, thereby reducing reservoir permeability. The purpose of the velocity sensitivity test was to determine the relationship between flow velocity and reservoir permeability for the completion fluids used. The test determines the critical velocity at which reservoir permeability starts to decrease.

The tests showed that the permeability of the reservoir cores decreased only slightly as the fluid flow velocity increased. Thus, this formation had very little velocity sensitivity.

Various types of drilling and workover fluids have different salinities. The partial salinity of a reservoir will change after the well fluids invade the formation and make the clays swell, disperse, and migrate. In such cases, the permeability decreases. Thus, tests were run to determine the effect of working fluid salinity on reservoir core permeability (Table 3 [30293 bytes]).

The tests determined that more formation damage occurred for fluid salinities less than 2,000 mg/l. In the field, the drilling and completion fluids were made with surface water with a salinity generally greater than 2,000 mg/l. Thus, there was little damage to the formation due to low salinity.

The next tests determined the effects of pH on core permeability (Table 4 [28107 bytes]). These tests clearly showed that permeability dropped significantly as the pH of the working fluid increased. When the pH was 12, the formation permeability decreased about 64%.

The damage to the cores from high pH was analyzed with a scanning electron microscope (Fig. 1 - top). The upper photograph in the figure shows the clay mineral structure clearly before damage. The bottom photograph shows the damaged and disordered clay structure after the core was flushed with high-pH fluids.

Based on these tests and the basic reservoir characteristics, the majority of the formation damage occurred from the high pH of the drilling and completion fluids which invaded the formation. The pH value of the drilling fluid filtrate was about 9 and that of the cement slurry reached as high as 13.

Several measures were undertaken to limit damage from these high-pH fluids.

- A thin, very low-permeability inner filter cake may be formed by changing the particle size distribution of the drilling fluid (Table 5 [27836 bytes]). This thin filter cake limits invading filtrate from the drilling and cementing fluids. The permeability of the inner filter cake can be reduced to zero by using a varied-shape particle distribution. In practice, the filter cake permeability is low and greatly limits filtrate invasion from the drilling fluids and cement.

- Underbalanced, deep perforating is used to bypass any near-well-bore damaged areas and to avoid invasion by completion fluids.

These protective procedures were used in eight wells in the Dong He reservoir. Well logs showed low depths of fluid invasion in these wells. All of these wells had high production and low skins (Table 6 [11721 bytes]).

Copyright 1997 Oil & Gas Journal. All Rights Reserved.