Gas flow to start in line from Algeria to Spain

Armel H. M. Morvan

Bechtel Petroleum Corp.

Houston

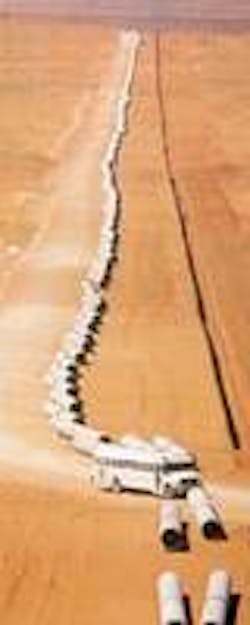

Pipe strung along the GME route between Algeria and Morocco awaits make up. (Photograph courtesy Bechtel Petroleum Corp., Houston)Construction of Phase 1 of the 858 mile, 48-in. Gazoduc Maghreb Europe (GME) was complete by the middle of October. Initial design of the line called for it to take gas from Algerian oil and gas fields, through Morocco, across the Strait of Gibraltar, into Spain.

Subsequent gas contracts have warranted an extension, currently under construction, from Cordoba, Spain, into Protugal.

GME will begin gas deliveries to Cordoba by the end of this month.

Gas fill to Cordoba was completed in late September. In October, normal operation awaited only sufficient line pressure through to Morocco and Spain, a process expected to be completed by Nov. 1.

At that time, first commercial gas sales were to occur at the Algerian-Moroccan border.

The section from Cordoba to the Spain-Portugal border has been essentially completed as well as the transmission lines in Portugal. The only missing link remains the section across the border which is to be completed by yearend. Commercial operation all the way through Portugal is due in first quarter 1997.

Installation of the line became possible because of the convergence of several market and political forces.

The main Algeria-Spain segment of the project will cost nearly $1.9 billion. When the segment to Portugal is added in, the cost could reach $2.4 billion.

One of the more difficult segments of GME is the 29-mile twin pipeline crossing of the Strait of Gibraltar. The challenges of this segment are covered in an accompanying article.

Maghreb group

"Maghreb" refers generally to a group of northern African countries (Tunisia, Algeria, Libya, and Morocco), two of which are involved in the project. The pipeline will transport natural gas from the Algerian gas fields through Algeria and Morocco, across the Strait of Gibraltar, into Spain and Portugal (OGJ, Feb. 5, p. 27; Sept. 26, 1994, p. 44; July 25, 1994, p. 32; and Jan. 17, 1994, p. 49).

Bechtel International Inc. was responsible for execution of the GME project in Algeria under the terms of a lump sum contract with Sonatrach, the Algerian state-owned petroleum company.

The Spanish gas company Enagas, Madrid, is developing downstream segments of the line, from the Algerian-Moroccan border into Spain. Enagas and Transgas, a Spanish-Portuguese consortium of companies, are owners and developers of the transmission lines to and inside Portugal (Fig. 1 [57416 bytes]).

Algeria's oil and gas fields, primarily Hassi Messaoud, In Amenas, In Salah, are mostly located in the Sahara (which covers 70% of the country) and generally south of Hassi R'Mel by 500-1,000 km or more.

The concept of moving natural gas to Europe by pipeline from Algeria has been around for awhile. Studies were performed in the early and mid-1970s to lay a gas line across the Mediterranean Sea, directly from Algeria to Spain.

At that time, however, political differences prevented such a pipeline from crossing Morocco. And technical difficulties prevented the alternate more direct, deepwater crossing to Spain.

Building a three-country alliance was required to allow development of the project. The alliance was expanded to include Portugal.

With the dissipation of political tensions, several economic forces converged to make the project economical:

- Algeria wanted to increase its gas exports.

- Algerian natural gas is abundant and of good quality.

- Gas delivered by pipeline is more economical and reliable than the LNG alternative.

- Morocco needed the gas for domestic use and industrial development.

- Spain had to satisfy increasing demands in energy and preferred the cleaner natural gas over nuclear power.

- Portugal was looking for a new source of energy to satisfy its rapidly expanding economy.

The first Algerian/Moroccan work group was established in July 1988. In April 1991, Sonatrach concluded a gas-sales agreement with Morocco and Spain. Because Portugal joined the group in April 1994, a branch line is being built from the GME in Spain to Portugal.

Eventually, the GME will extend to northeastern Spain and to France to connect to the European natural gas grid.

Segments

The 807-mile line runs from the Algerian gas fields to Cordoba and represents more than 600,000 metric tons of high strength steel. The additional segment from Cordoba through Portugal adds approximately 311 miles.

GME is being built in four distinct segments:

- 323 miles of cross-country pipeline through the high plateaus of Algeria in relatively flat desert terrain, except near the mid-point where the line crosses the Saharan Atlas mountains. Soils are mostly rocky.

- 335 miles of cross-country pipeline entering Morocco over high plateaus, continuing between the Atlas and Rif mountains to the coastal plain, and turning north to reach the Strait of Gibraltar west of Tanger.

- 28.5 miles of submarine crossing of the Strait of Gibraltar by two 22-in. pipelines in waters nearly 400 m deep with relatively high currents.

- The beach landing in Spain and 171 miles of mostly 48-in. pipe to Cordoba with a branch line continuing on to Portugal.

Sizing of the line to 48 in. was based on conceptual studies and economic analyses to design a pipeline system capable of satisfying projected gas demand over its life.

The idea is to select the right combination of pipe size and number as well as size of compressors to match the planned growth in capacity. Pipe diameter should not be too large for the initial throughput to limit the initial investment but large enough to accommodate the ultimate design throughput.

For the Algerian section of the GME in Phase I (Table 1 [32377 bytes]), there is no compressor station. The 48-in. pipe is large enough and sufficient reservoir pressure is available in Hassi R'Mel to move approximately 1 million cu m/hr of natural gas up to the Moroccan border with no intermediate compressor station.

Phases; expansions

Table 1 [32377 bytes] shows the planned developments of the Algerian section of the GME.

Phase 1, currently under construction, will allow gas sales of up to 8 billion cu m/year (bcmy) with no compressor stations.

With addition of one compressor station in Phase II, roughly at the mid-point of the pipeline with three, 15,000-hp turbine-compressors (two operating and one on stand-by), this pipeline capacity can be increased to 12 bcmy.

In Phase III, two compressor stations will be added to the system to reach 15 bcmy.

And finally in Phase IV, to move 19 bcmy, two more compressor stations will be installed for a total of five. But one turbine compressor is added to each of the three previous stations.

The result is a 48-in. pipeline with five compressor stations, each with three turbine compressors operating and one on stand-by to meet the capacity requirements.

The growth phases of this multicountry project must be properly planned and implemented to meet the increase in gas demand from all users (Table 2 [7037 bytes]).

In Phase I, after traveling over the 323-mile Algerian section, the gas pressure has dropped because of friction losses, so that by the time it reaches the border, compressors are needed inside Morocco to transport the same 1 million cu m/hr up to the coast.

The same is true at the end of the Moroccan section to continue pushing the gas to Spain.

As a result, in Phase I, two compressor stations are needed in Morocco to move the natural gas to Spain: one just inside the Moroccan border from Algeria and one not far from Tanger.

As is the case for the Algerian section, compressor stations and turbine compressors will be added to the Moroccan section to meet the required pipeline capacity for each succeeding phase.

A third line will be added in Phase III across the Strait of Gibraltar to permit the staged increase in gas shipment to Europe.

About 90% of the line in the Algerian section has a 0.508-in. W.T., the heavier pipe (0.875 in. W.T.) being used for safety in special areas such as roads and railroads crossings. (See accompanying box on GME pipeline data).

The pipe is internally coated with epoxy to improve flow characteristics and externally coated with extruded polyethylene to prevent external corrosion.

The pipeline is designed to transport natural gas at pressures up to 1,015 psi.

Four pipe mills have been used to produce the pipe for the Algerian segment: one in France, one in Spain, and two in Algeria. Because it is preferable to be "safe than sorry," Sonatrach purchased an excess of 48-in. pipe which can be used on other projects.

The 217,000 metric tons of steel to manufacture the pipe have come from three European manufacturers (accompanying box).

The line pipe used for the Moroccan section is very similar to that used in Algeria. The wall thickness is slightly heavier, however, because the selected design pressure for the pipeline in Morocco is 1,160 psi rather than 1,015 psi in Algeria.

The design pressure for the Strait crossing is even higher, 2,248 psi. This pressure was selected to compensate for the fact that two 22-in. lines offer a capacity of less than half that of a 48-in. pipe at equal operating pressure.

Three pipe mills and steel suppliers participated in the supply of pipe for these two sections, totaling another 300,000 metric tons.

In addition to its buried pipeline, Phase I in Algeria consisted of the following facilities:

- Metering systems

- Supervisory and control systems

- Main line block valves allowing isolation of pipeline segments 20 to 30 km long

- Telecommunication support system via a new fiber-optic cable spanning the length of GME

- Radio communication systems

- Other support infrastructure such as buildings and power generation.

Similar facilities are installed for the Moroccan section, the section crossing the Strait of Gibraltar, and in the Spanish section of the GME (specified by location in the accompanying box).

The major exception is that two compressor stations are installed in Morocco during Phase I, as previously mentioned, one at the border between Algeria and Morocco and the other one near Tanger.

Fig. 2 [32377 bytes] shows the financing scheme of the Algerian section. The first pie pictures the financing assembled by Sonatrach to cover the supply of main line pipe.

In addition to Sonatrach's dinar participation (local currency), the German (Hermes), French (Coface), and Spanish (Cesce) export credit agencies supported the project, in addition to the European Investment Bank (EIB). As stated previously, all pipe steel came from European mills.

The Bechtel pie consists of U.S., French, German, and EIB credit guarantees, plus Sonatrach's participation in dinars.

The bottom pie (Fig. 2 [32377 bytes]) represents the overall level of participation of each country to the approximately $675 million cost of the Algerian section of the GME, excluding financing fees and owner's costs.

Fig. 3 [31563 bytes] shows the financing of the Moroccan and Spanish sections and differs only slightly from Fig. 2 in that new lending institutions and export credit agencies appear here while others have disappeared.

In addition, Enagas obtained vendors' credits pictured as "Deal" on this figure, mainly from Italy and the U.K.

These two pies correspond to a total investment in the order of $1.2 billion for the Moroccan and Spanish sections of GME, generally including financing fees, but excluding owner's costs.

To this, a further $500 million must be added to cover the cost of the transmission line from Cordoba to and through Portugal.

The approximate total cost of the GME at this stage can then be broken down by section: Algerian section, $675 million; pipeline across Morocco, $550 million; compressor stations in Morocco, $150 million; crossing the Strait of Gibraltar, $150 million; Spanish section up to Cordoba, $300 million; and from Cordoba through Portugal, $500 million. This adds up to more than $2.3 billion.

Based on a presentation to the International Pipe Line and Offshore Contractors Association Annual Convention, Istanbul, Sept. 17-21.

The Author

Armel H. M. Morvan is senior project manager for pipeline operations for Bechtel Petroleum Corp., Houston. Currently, he is project manager for the 520-km Algerian section of GME. Among other positions he has held since joining Bechtel in 1974 are engineering manager for pipeline operations, study manager for several major pipeline projects, and field engineering manager for the Occidental de Colombia pipeline.

Morvan holds a BS in civil engineering from Ecole Spciale des Travaux Publics, Paris, and is a registered professional engineer in California.

Copyright 1996 Oil & Gas Journal. All Rights Reserved.