Conoco inaugurates new unit at its U.K. Humber refinery

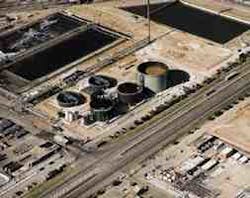

Conoco's new vacuum distillation unit (left) at Humber refinery will enable the company to process a wide variety of North Sea crudes, particularly the acidic crudes expected on stream in the near future. Aerial view shows the new wastewater treatment unit (below) at the Humber refinery. In addition to installation of a new biotreatment plant and upgrading of separators, the project also involved construction of a 1-mile, 48-in. sewer pipe to divert a drainage channel.Conoco (U.K.) Ltd. has inaugurated a £ 15 million ($22.5 million) wastewater treatment plant at its U.K. Humber refinery, part of its £ 400 million ($600 million), 1993-2000 investment program.

The plant contains an activated sludge unit, in which bacteria digest contaminants in refinery wastewater. The plant will typically process 16 million l./day of waste water.

Conoco also upgraded oil/water separators and installed a new air flotation unit to remove oil from wastewater prior to biotreatment.

The project also involved rerouting the Killingholme Ditch, a drainage channel taking water from the refinery and a nearby village to the Humber estuary.

Conoco said the ditch was diverted around the refinery instead of through the plant, as surface runoff from the village was able to overwhelm the effluent treatment plant in bad weather.

New distillation unit

Conoco has spent almost £ 250 million ($375 million) at the refinery since 1993, the largest single project being a recently completed vacuum distillation unit which cost £ 85 million ($130 million).

The new 54,000 b/d capacity vacuum distillation unit is the only one in Europe able to handle unblended acidic crude oil. It is built with a corrosion-resistant stainless steel grade.

Refinery Manager Terry Indreland explained the need for the new unit: "Currently, about 6% of the crude oil produced in the North Sea has high acid content, but by 2000, as new oil fields come on stream, the percentage of acid crude will double.

"These crudes are corrosive when heated, so conventional refineries must limit the amount they introduce into their process stream. At the same time, imports of heavy intermediate feeds needed for our conversion process are becoming more expensive and less available.

"This new unit allows us to process the high-acid crudes and produce more of our own heavy conversion-unit feedstocks."

The new unit is the third vacuum distillation plant at the refinery; two existing units have combined throughput capacity of 120,000 b/d.

Humber refinery has crude distillation capacity of 170,000 b/d, plus capacity to process 50,000 b/d of heavy intermediate feedstock.

Future projects

Conoco's further investments at Humber refinery, said the official, will include general expansion and upgrading projects, especially of its coking plant.

Vapor recovery equipment will be installed at the refinery's rail and ship loading terminal in a £ 20 million ($30 million) project, and the No. 1 sulfur recovery unit will be upgraded at a cost of £ 3.3 million ($5 million).

In addition, a £ 20 million ($30 million) combined heat and power project is to be built at the refinery by electricity generator Powergen plc. This will make the refinery self-sufficient in electric power with excess power for sale.

Work in progress includes a £ 26 million ($39 million) calciner, due to be commissioned next year, to increase output of petroleum coke. Humber is the only U.K. refinery to produce petroleum coke.

Copyright 1996 Oil & Gas Journal. All Rights Reserved.