Kazakhstan's Karaganda basin offers CBM developmenet prospects

Scott Thomson

Duncan Thomson

CoalBed Energy Consultants Pty. Ltd.

New Lambton, Australia

Bolat Khassen

Institute of Complex Mineral Development

Karaganda, Kazakhstan

Abdikarim Zeinullin

Kazakhstan National Academy of Natural Sciences

Astana, Kazakhstan

The coal-bearing Karaganda basin in central Kazakhstan could contain up to 10 tcf of unconventional gas according to results of an exploration and pilot production program in the Taldykuduk area.

The Karaganda basin is one of the oldest and most studied coal-bearing basins in both Central Asia and the former Soviet Union. It has sustained a coal industry for more than a century and has sufficient coalbed methane (CBM) potential to provide Kazakhstan with an ample domestic supply of natural gas.

Gas deposits in the Karaganda basin have proved problematic for mining operations. Despite the presence of CBM, however, no gas development has been undertaken. This article presents findings from more than 5 years of field work studying gas desorption, gas composition, adsorption isotherms, and permeability testing. This is the first systematic collection of CBM-specific data from the Karaganda coal basin and the Karaganda coal measures (K seams). Further studies are warranted, with the emphasis on securing access to an area with enhanced structural flexure and greater permeability.

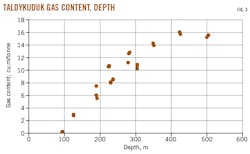

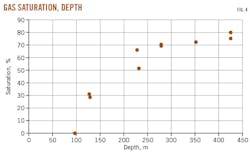

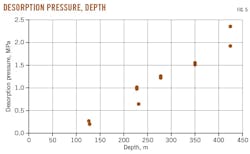

The pilot program is 22 km southwest of the city of Karaganda in the Taldykuduk area. The Karaganda basin's K-seam series have high gas contents-10-16 cu m/tonne dry, ash free (DAF)-at 300-500 m, are dominated by methane, and exhibit 70-80% gas saturation from 220 m depth. The coals' permeability is tight by international standards, usually < 3 md, as confirmed by limited production testing. This article identifies trends for increased gas content versus depth, moderately static gas saturation from 220 m, and a linear relationship between desorption pressure and depth. Permeability also decreases rapidly with depth.

The underlying study also investigated the relationship between initial reservoir pressure and desorption pressure, showing that Karaganda coals have a ratio of 0.4-0.6 and therefore are likely suitable for commercial CBM development. Despite its commercial potential, the Taldykuduk area's ubiquitous low permeability could inhibit production, but further study is warranted for either conclusion.

Geology

The Karaganda basin is a Carboniferous-age, coal-bearing sequence in central Kazakhstan (Fig. 1).1-3 The basin also contains Upper Devonian, Mesozoic, and Cenozoic formations. It covers an area of 3,600 sq km, which is 120 km long by 30-50 km wide and reaches a depth of up to 4,500 m.

The coal basin is divided into three distinct mining areas based on geological structural divisions: Karagandinskiy, Sherubay-Nuriniskiy, and Tentekskiy. Taldykuduk is part of the Karagandinskiy division. The tectonic history of the basin is complex, and coal measures are affected by many anticlines and synclines. The basin is also extensively faulted. Seam dips vary from near horizontal to up to 40°. The surface topography is predominantly flat, consisting of characteristic steppe landforms with occasional small hills.

Karaganda basin's Carboniferous coals are of excellent quality, with inferior coal occurring in the Mesozoic formations. Karaganda along with Donbass and Kuzbass were the former Soviet Union's three major producing coalfields.1 There are eight deep underground coal mines in the district using retreat longwall methods, producing 10 million tonnes/year of metallurgical and thermal coal.2 The coals are known to be gassy with low permeability, creating major mining safety and productivity issues.4

Karaganda's Carboniferous coals rank medium-low volatile bituminous to semi-anthracite. Maximum vitrinite reflectance (RoMAX) varies from 0.86-1.47%, averaging 0.99-1.26%. Vitrinite and inertinite are the dominant macerals.

The basin contains up to 80-100 m of net coal. Seams are heavily structured and may be discontinous due to faulting and syndepositional sedimentology. The low moisture and low-moderate ash of the K seams, coupled with the favorable rank, suggest the coals of the Taldykuduk are suitable for CBM development.

Kazakhstan's government has recognized CBM as a source of untapped unconventional gas and funded much of the work conducted in this study.5 The test site in Taldykuduk is removed from current mining activities, representing virgin gas conditions. Exploration work undertaken during the Soviet era showed the area contained a thick coal sequence with high gas content (Fig. 2).6 The work carried out to date at Taldykuduk is relevant to CBM in other parts of Karaganda and more broadly throughout Kazakhstan.

Previous study

Two distinct exploration studies were carried out in the Taldykuduk area in 1938-60 and 1982-88. Both studies investigated coal properties for potential mining, not CBM. Neither study conducted direct gas testing.

In the first exploration period teams conducted preliminary reconnaissance and detailed exploration to a maximum depth of 500 m, drilling a total of 80 wells mostly concentrated in the eastern and northeastern parts of the area. Most wells did not exceed 300 m depth. An additional period of exploration concentrated on the south and central parts of the area. This work established the extent and thickness of coal for the Karaganda suite and delineated the folded structure present in the central part of Taldykuduk, finding that tectonic disturbances complicated the structure. These studies established that the southern part of the site had an extremely complex structure. Subsequently, researchers decided to concentrate exploration work in the central and northern parts.

During 1955-57 teams conducted preliminary exploration of the entire central part of the area, drilling a network of exploration wells between 1958 and 1960 in the central and northwest parts. Geologic structural complexity required 250-m spacing between each well. The work established the correlation of seams, their thickness and structure, and qualitative characteristics.

Review of this early exploration data concluded that the area possessed potential for commercial CBM development.

Many authors, particularly during the Soviet era, studied the broader Karaganda's coal properties, recognizing the potential for CBM.

The Kazakh-British Technical University in Almaty, responding to political directives to "green" Kazakhstan's economy, produced a paper that was supportive of CBM's role in the future energy mix.5

The US Environmental Protection Agency (EPA), through the Coalbed Methane Outreach Program, provided detailed analysis of the coal gas properties of the Karaganda basin based on mine-related studies.2 3 The EPA studies were undertaken partly in parallel with, and as an extension of, similar work undertaken by the European Union's CoMeth Seventh Framework Program.1 The major thrust of CoMeth and EPA involvement was to provide the technological support needed to justify gas capture and use at the mine site, reducing pollution and enhancing onsite electricity generation.

Recent work

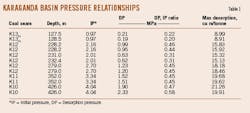

The Institute of Complex Mineral Development (IPKON) carried out exploration work at Taldykuduk from 2013 to present. The program's exploration phase confirmed the seam gas properties and provided potential targets for pilot testing (Table 1).

The CBM work had a primary objective of producing methane from a pilot well. Boreholes completed as part of this work program included:

• A pseudo horizontal lateral well (T1) targeting a single thick coal sequence (K12 seam) drilled by Atlas Copco RD20 40t.

• An exploration core well (T3) designed to gather key reservoir information. Budgetary constraints required the ommission of permeability testing.

• A deep openhole reamed pilot well (T2) drilled as a conventional standard cased and reamed vertical CBM well. The pilot well encountered five coal seams (including K12).

• Exploration core wells-T5, T5-4, and T9-designed to gather key additional reservoir information, including permeability testing.

• A shallow openhole reamed well (T7) designed as a conventional standard cased and reamed vertical CBM well targeting coals not exceeding 400 m.

• A shallow hydraulically fractured well (T8) targeting shallow coals (~300 m) for fracture stimulation.

This exploration program resulted in a total of 48 desorption tests on 17 selected coal intersections. Isotherm testing established the critical desorption pressure (CDP) for all key CBM target seams, K12 in particular. The study also conducted some drill stem tests (DST). No permeability results exceeded 3 md.

Results for the pilot production program were similar in almost every case, with very low gas- and water-production rates. Review of the production performance of each of these wells led to the conclusion that low permeability is likely to be a serious inhibitor of CBM performance in the Taldykuduk area.

Coalseam gas properties

The exploration program conducted gas desorption studies according to international standard procedures using the US Bureau of Mines slow method. Further studies determined gas composition using a gas chromatograph in the field and laboratory.

Gas content is high in Tadykuduk field, with up to 12 cu m/tonne DAF at 300 m (Fig. 3), noting a clear trend of increasing gas content with depth at around 3-5 cu m/tonne per 100 m (200-400 m interval). This result shows parallels with medium-high rank coals in other international coalfields.7 Gas content is below measurable limits until 100 m, then increases rapidly with depth to 400 m, after which the rate of increase flattens.

The dominant seam gas at Taldykuduk is methane (95%+), with a small proportion of higher hydrocarbons (ethane, propane from 0.1 to 2.6%). The remainder is CO2.

This study conducted sorption isotherm work on samples from the K10, K11, K12, and K13 seams from the T5, T5-4, and T9 wells. Early work suggests an increase in gas saturation with depth (Fig. 4), reaching a peak of about 79% at 426 m. Saturation is consistently around 70-80% from 220 m to the final depth of analysis (426 m). Gas loss gradually increases towards the surface and declines asymptotically to 0 close to ground level.

Desorption pressure was calculated based on the results of isotherm work to date. Desorption pressure increases linearly with depth from 1 MPa at a depth of 228 m to 1.96 and 2.41 MPa at a depth of 426 m (Fig. 5). This linear increase implies that a 116-145 m reduction in the water column in a well will be required for K10 and K12 seams in this area before gas will flow.

In general, the higher the desorption pressure (relative to initial reservoir pressure), the greater the efficiency of the coal seam for producing gas. This ratio should be at least 0.3 for productive CBM extraction.8 For Karaganda coals at normal CBM extraction depths (>100 m) desorption pressure relative to the initial pressure is generally 0.45-0.49, and in one of the samples reached a value of 0.58 (Table 1).

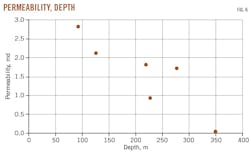

Coal permeability studies continue, but DST data analysis and pilot well results suggest that the Taldykuduk coals have exceedingly low permeability. DST work from the K11, K12, and K13 seams has established that permeability at a depth of 225-280 m is 1.0-1.8 md and decreases to 0.01 md at a depth of 350 m (Fig. 6). Permeability testing for K12 registered a 2-cu m/d average inflow of water from the coal seam.

CBM potential

The coals from the Taldykuduk area of the Karaganda basin show many favorable attributes consistent with international producing CBM fields. Net coal is extremely high, rank is appropriate for substantial volumes of gas to be present, and gas content and composition have proven to be favorable. Gas saturation is generally moderate-high but declines rapidly from 200 m depth to the surface. The major impediment to commercial development remains the low permeability endemic to the field.

Low permeability and high gas content are recognized as major problems in the associated coal mines in the Karaganda basin and the first of these properties is also a barrier to large scale CBM development, at least in the areas that have been studied. Table 2 compares Taldykuduk coals to those of producing international CBM sites.

Moving forward in the Karaganda basin depends on successful delineation of a structurally relaxed zone exhibiting enhanced permeability. An analogue would be the Comet Ridge in the otherwise ubiquitously low-permeability Bowen basin in Australia. Given the high levels of fracturing to which the coals have been subjected, it is conceivable that such a sweet spot exists. Favorable gas contents, compositional quality, and the sheer volume of gas available in the thick net-coal sequence suggest the possibility of a flourishing CBM industry in Karaganda.

Permeability, however, remains universally low in the Taldykuduk area and if this property of the coals applies more regionally then commercial development may be inhibited. Reconnaissance work, including seismic reflection surveys and further reservoir analysis, is required to progress understanding of the availability and size of suitable targets.

References

1. Tyduk, D., Aspanov, K., Mroz, A. Backhaus, C., and Zeidler-Fandrich, B., "Report on the WP7 - Potential analysis for CMM utilization in Kazakhstan and concepts for CMM utilization," CoMeth, Coal Mine Methane - New Solutions for Use of CMM - reduction of GHG emissions, European Commission Seventh Framework Program (2007-2013), 2010.

2. US Environmental Protection Agency (EPA) Outreach Program, "Deep Gassy Coal Mines of Karaganda Coal Basin," December 2011.

3. US EPA Coalbed Methane Outreach Program, "ArcelorMittal Coal Mines Karaganda Coal Basin, Kazakhstan: Pre-feasibility Stidy for Coal Mine Methane Drainage and Utilization," April 2013.

4. Baimukhametov, S., "Development and mining of high gas low permeability coal seams in the Karaganda coal field - Kazakhstan," 12th Coal Operators' Conference, University of Wollongong and The Australian Institute of Mining & Metallurgy, Wollongong, Australia, Feb. 11, 2012.

5. Sabitova, D.K., "Exploration potential of Coalbed Methane in Karaganda Field," Canadian Center of Science and Education, Modern Applied Science, Vol. 9, No. 6., June 2015.

6. Saran Party, "The Search and Evaluation work at the Lower Levels of Taldykuduk Plot of the Karaganda Region of Karaganda Coal Basin," Unpublished Soviet era internal document, Book I, p. 334, 1989.

7. Thomson, S., Thomson, D.S., and Flood, P.G., "Observations on the distribution of coal seam gas in the Sydney Basin and the development of a predictive model," Australian Journal of Earth Sciences, Vol 61, No. 3, May 15, 2014, pp. 395-407.

8. Zhao, J., Tang, D., Xu, H., Lv, Y., and Tao, S., "High production indexes and the key factors in coalbed methane production: A case in the Hancheng block, southeastern Ordos Basin, China," Journal of Petroleum Science and Engineering, Vol. 130, June 2015, pp. 55-67.