Shear test, stress analysis predict collapsing pressure in China's Liushagang shale

Lixi Liang

Yi Ding

Xiangjun Liu

Southwest Petroleum University

Chengdu, China

A new study uses shear tests and seepage-stress analysis in north China's Liushagang formation to create a model that predicts collapsing pressure and avoids costly drilling delays in hard, brittle shales.

Like other formations of its kind, Liushagang has a strong hydration capacity as well as many bedding planes and microcracks. Drilling in these rock conditions can create wellbore instability and the potential for collapse.

In this study, shear tests were used to assess the strength of Liushagang's bedding planes and rock matrices before and after soaking in drilling fluid. Results show that a weak plane has significant effect on wellbore stability and that hydration increases its effect over time. Porosity tests were conducted to analyze the change in rock space affecting the accuracy of seepage-stress estimations while drilling.

Predictions from a wellbore-stability model created using Liushagang's bedding plane, hydration, and seepage stress data were a strong match with field data.

Scanning Liushagang shale

Brittle, hard shale was taken from the Liushagang formation and a scanning electron microscope used to observe its microstructure characteristics. Microcracks and micropores were predominant, contributing to drilling fluid invasion.

The shale consists of rock mass and bedding planes, which have different mechanical properties from each other. In vertical and horizontal bedding planes, shear tests were conducted to assess mechanical parameters after soaking in fluid for different lengths of time.

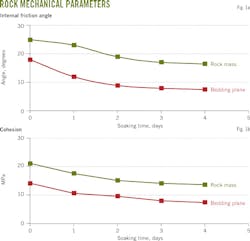

Fig. 1 illustrates that matrix and bedding-plane strength decline with increased soaking. The mechanical parameters of bedding planes and rock mass have a similar declining trend. During the first 2 days, there is a steep decline before it levels off to nearly flat.

The bedding plane's angle of internal friction and cohesion shows a greater range of decline than the rock matrix. This means that the bedding plane is more sensitive to drilling fluid.

After soaking in drilling fluid, the invasion is obvious. Cracks that propagate on the rock surface make this invasion more severe.

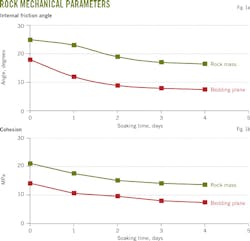

The porosity of core samples was tested by soaking them over different time durations, thus quantifying the damage done by drilling fluid in shale rock spaces. Fig. 2 shows porosity growing quickly over the first 2 days, after which the trend is moderate. This tendency is similar to the decreasing strength trend, indicating a corresponding relationship.

Determining stresses

Seepage stress in the wellbore wall occurs when drilling fluid is in contact with the formation. Seepage is not a constant value and changes over drilling time (see table). The change in seepage over time depends on two factors: pore pressure and rock space.

Cracks propagate through mud invasion and hydration effects that change the space in rocks and, therefore, the seepage difference. The relationship between space and soaking time is expressed in Equation 1.

Pore-pressure change around borehole is an osmotic phenomenon between shale and drilling fluid. Shale can be regarded as a semipermeable membrane. Temperature gradient and electrical-potential gradient are ignored, and hydraulic pressure and the osmotic-pressure gradient used. Equation 2 shows the general equation for solvent transport in shales.

Initial conditions and boundary conditions are still needed to confirm pore pressure around borehole. Based on an infinite radial-flow field with axial symmetry, two initial conditions and four boundaries can be obtained (Equation 3).

When pore pressure and rock space are confirmed, we assume the formation is a porous medium and that pore flow follows Darcy's law. Equation 4, then, can determine seepage stress.

Using linear-elastic mechanics and transverse isotropy, effective stress around the borehole of any anisotropic geologic medium can be written as Equation 5.

The three principal stresses in a borehole medium can be calculated using Equation 6. Direction of maximum stress is expressed in Equation 7. Equation 8 defines bedding-plane direction, and Equation 9 the direction vector of maximum principal stress.

Combining the results of Equations 8 and 9 determines the angle between a bedding plane's normal and maximum principal stress (Equation 10).

Shale has two types of failure models. Based on the Mohr-Coulomb criterion, rock failure along the bedding plane, can be expressed as Equation 11. Failure in the rock mass can be expressed as Equation 12.

Influencing factors

Formation parameters were among several factors influencing the Liushagang study. Pertinent data included:

• Formation depth, 2,280 m.

• Overburden pressure, 49.5 MPa.

• Maximum horizontal in situ stress, 44.3 MPa.

• Minimum horizontal in situ stress, 38.2 MPa.

• Pore pressure, 24.6 MPa.

• Porosity, 7.2%.

• Poisson ratio, 0.2.

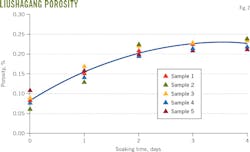

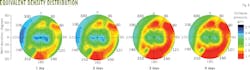

Fig. 3 demonstrates the influence of different bedding planes on wellbore stability. Red areas show where collapse is likely due to high mud weight. Blue and black areas are stable.

Collapsing pressure distribution can change depending on the bedding plane, becoming more complex. When the dip angel is certain, the distribution is axial symmetry with 90° azimuth. When the dip azimuth is uncertain, there is no pattern.

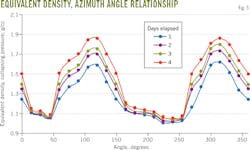

Fig. 4 demonstrates the influence of drilling fluid on collapsing pressure. The potential for collapse increases as mud weight increases. Collapsing pressure changes dramatically between Day 2 and Day 3.

The table highlights the influence of seepage stress in the wellbore wall. Seepage stress changes were determined by analyzing collapsing pressure at different azimuth angles (Fig. 5). In some parts of azimuth (20-50° and 160-270°), seepage stress change has very little impact on collapsing pressure. But in other azimuth angles (90-130° and 290-330°), the influence was significant. The greatest variation of collapsing pressure, caused by seepage stress, is about 0.28 g/cc.

Field application

The model was applied to a well where collapses are frequent: WS17-2-1. Research depth is 2,100-2,300 m, where there are hole-enlargement problems that increase the chances of collapse.

Based on field data, the bedding plane has a dip angle of 18° and an azimuth of 20°. Wellbore deviation is 23° and azimuth is 320°. Overburden pressure is 48.7MPa. The maximum and minimum horizontal in situ stress is 42.5MPa and 34.6MPa. Pore pressure is 24.3MPa. Porosity is 7.6% and Poisson ratio is 0.23.

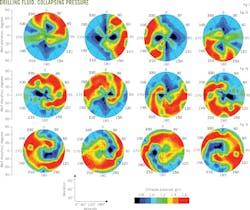

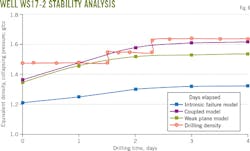

Fig. 6 shows the different models that were applied to analyze well WS17-2-1. The comparison illustrates that the intrinsic model is not applicable for a brittle, hard shale formation.

The weak-plane model is applicable over the first 2 days but less effective over time, indicating seepage stress cannot be ignored in late drilling stages. Our coupled model proved to be more accurate in determining collapsing pressure in these formations.

Acknowledgment

The authors thank the National Natural Science Foundation of China (U1262209) and the National Science and Technology Major Project of the Ministry of Science and Technology of China (2011ZX05020-007-06) for supporting the work that resulted in this article.

The authors

Lixi Liang is a lecturer in the oil and natural gas engineering institute, Southwest Petroleum University, Chengdu. He holds a PhD in wellbore stability and rock mechanics from Chengdu University of Technology.

Yi Ding is a postgraduate student in the oil and natural gas engineering institute, Southwest Petroleum University, Chengdu. His research interest is focused on wellbore stability. He is an SPE member.

Xiangjun Liu is a professor at Southwest Petroleum University, Chengdu, and dean in the school of geoscience and technology. Liu holds a PhD in rock mechanics and petrophysics from the same university.