Modeling ensures stability of Chinese CBM horizontal wells

Jie Zhang Hu Liu

State Key Laboratory, Chengdu, China

Guangjie Yuan Yan Xia

Chinese National Petroleum Co.

Beijing

Successfully drilling horizontal coalbed methane wells depends on wellbore stability, which in turn depends on coal-seam thickness, seam depth, coal cohesion, overburden stress, wellbore length, reservoir pressure, and the drilling fluid used.

It is important to understand the sensitivity of the wellbore and the potential yield under different horizontal in-situ stresses, bottomhole pressures, and formation pressures when drilling.

Where there are numerous thinner coal seams with reasonable permeability (5-10 md), vertical drilling is preferred. When only one or two thick seams with high-gas content but low permeability (< 2 md) are present, horizontal drilling should be considered and, often, is the only option available to economically produce the gas.

This article analyzes wellbore stability for a horizontal coalbed methane well in Qinshui basin, China. It looks at the coal rock, it's water absorption rates, stresses, and mechanical properties to determine how best to ensure wellbore stability when drilling Qinshui wells and others with similar properties.

Rock properties

The southern Qinshui basin has the most coalbed methane in China. The most abundant coal-bearing strata are the Taiyuan formation of carboniferous upper trunk (C3t) and the Shanxi formation of Permian lower trunk (P1s).

The average thickness of the coal is 163.02 m. There are 17 seams with a coal-bearing coefficient of 9.1%. These include two minable coal seams that are about 10.70-m thick at a depth of 350-1,300 m, and characterized by interbedded, fine-grained sandstone, mudstone, silty mudstone, and thick coal seams.

There are two large geological folds in the Qinshui area studied in this article: syncline f1 and anticline f2. The overall geological structure is simple.

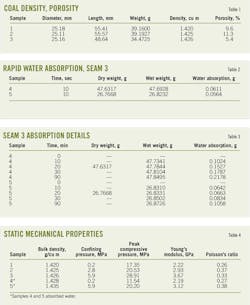

The cores analyzed in this article came from coalbed Seam 3 in the southern part of the basin from an average depth of 560 m. Analysis included tests to determine density, porosity, water absorption, acoustic time, and uniaxial and triaxial rock strengths. Table 1 shows test data.

Water absorption

Compared with sandstone, coal's density is low and its porosity is developed. The core samples contained little or no clay minerals and hydration capacity was quite low. Their microfissures, however, developed with a large surface area containing more hydrophilic and lipophilic surfaces than in sandstone.

Instantaneous and accumulated-water absorption rates show that, under capillary pressure, water quickly entered the coal cracks and voids (Tables 2 and 3). As the water absorption time improved and the absorption rate dropped dramatically, water spread out and adsorbed into the rock sample.

Vertical, horizontal stresses

To calculate vertical stress or stress gradient at a given depth one would generally use a bulk-density log to first calculate lithostatic gradient. No density log data were available for this study. We instead used the formula demonstrated in Equation 1. Our in-situ stress test used the acoustic-emission Kaiser experiment under the condition of confining pressure. Applied confining pressure was meant to improve the sample's compressive strength and the exact measured value of the sample at the acoustic-emission Kaiser stress points.

The average coal-pore pressure of the study area was 5.9 MPa, setting the confining pressure in this experiment at 5 MPa. Based on the experiment's results, the maximum and minimum horizontal main stresses were 12.82 and 8.76 MPa respectively, and the maximum and minimum horizontal main stress gradients were 2.289 and 1.564 MPa/100 m, respectively.

Properties, effective stress

Table 4 shows the static mechanical properties of three samples. In the triaxial test, all three showed characteristics of brittle rock that retained some degree of residual strength after damage.

As confining pressure increased, both the maximum compressive strength and residual strength of the rock increased as well. The samples' water absorption led to reduced compressive strength within a margin of 30%.

The slope of the linear portions of the axial-stress difference and axial-strain curves determined the static Young's modulus values, the ratio of the longitudinal tensile stress, and the tensile strain.

The static Young's modulus of dry-rock samples ranged from 2.22 GPa to 3.67 GPa. That of rock after absorbing water was 2.08-3.12 GPa.

The slope of the linear portions of the average radial strain and axial radial strain curves determined the static Poison's ratio values. The static Poison's ratio of the dry sample in this article was 0.26-0.37, with an average of 0.32. The ratio after absorbing water was 0.27-0.38.

Equation 2 calculated effective stress under the triaxial test.

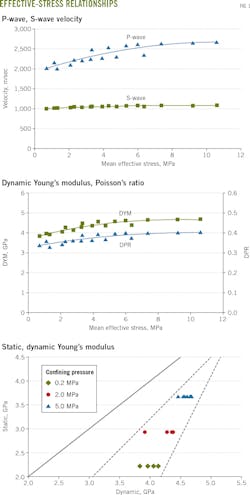

Table 5 shows the dynamic parameters of the dry rock and the acoustic test data. Fig. 1 illustrates the stress dependency of the P-wave and S-wave velocities and of the dynamic elastic parameters. As effective stress increases, the P-wave and S-wave velocities increase, as do the dynamic elastic parameters.

Coal-rock strength

Orthogonal cleats in the coal bed cause high discontinuity in coal rock, making the rocks' mechanical properties non-continuous and non-linear.

The Hoek-Brown strength criterion assumes that rock mass is isotropic and is applied to rock-mass formations that have been discontinuously and intensively developed. These discontinuities have similar surface features, which can be considered isotropic damages along the discontinuous surface. These similarities allow analysis of the stability of a coalbed well wall using this criterion.

Equation 3 expresses the Hoek-Brown formula.

To get more accurate rock mass parameters, Hoek et al. introduced the parameter of geological strength index (GSI). GSI's value is related to the integrity, joint count, number of cracks, and surface condition of the coal rock.

If the coal-rock surface is in good condition and has a mosaic shape, GSI would be 55-100. If the coal-rock structure is affected by multiple sets of discontinuities cutting one other, GSI would be 45-55.

Determining GSI, allows calculating Hoek-Brown rock mass parameters using the formulas expressed in Equations 4, 5, and 6 The disturbance factor, D, used in these equations reflects the degree of rock blasting damage and stress release using a 0 to 1 range; the D of undisturbed rock = 0, and that of the strongly disturbed rock = 1.

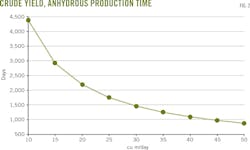

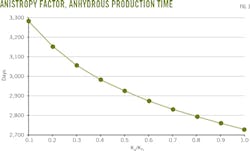

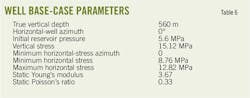

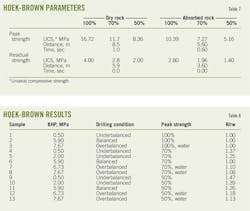

We adjusted our analysis to fit the data of previous stud ies where lower values were obtained. This discrepancy in data required only 70% of the experimental data be analyzed (Tables 6 and 7). The nonlinear Hoek-Brown rock-strength criterion envelope, which corresponded to different circumstances, was also derived (Fig. 2).

Borehole stability

When the stress around the well exceeds the compressive strength of the rock around the well wall, the compressive strength is reduced and the well wall plastically deformed, followed by partial or total collapse. Debris will converge at the well bottom, and sticking will occur if the rock-carrying capacity of the drilling liquid is insufficient to clean up the debris from the wellhead.

The size, R, of the wellbore's plastic zone under in-situ stress requires consideration, as does drilling fluid pressure. Software simulation predicts the range of plastic deformation of rock around the wellbore.

When vertical stress is the maximum principal stress, the trajectory of the horizontal well along the minimum horizontal principal stress direction is the least prone to collapse. Table 7 shows the rock-strength parameters and in-situ stress. Setting different bottomhole pressures (BHP) allowed simulation of overbalanced, near balanced, and underbalanced drilling.

The maximum BHP was 130% of reservoir pressure, and the minimum BHP was 0.5 MPa. When overbalanced, the rock strength parameters demonstrated conditions similar to those from the water-absorbing rock samples. When near-balanced and underbalanced, conditions adopted the parameters from the dry rock samples.

Hoek-Brown analysis used 100%, 70%, and 50% lab peak-strength values. Analysis using 100% lab peak-strength values predicted no yielding (Table 8). Applying 70% peak-strength values didn't predict yielding until BHP was reduced to 2 MPa. When 50% peak-strength values were used, the predicted yield-zone radius was largest at the same 2 MPa.

Acknowledgments

The authors would like to acknowledge the financial support of the Natural Science Foundation of China (NSFC) (No. 51274168).

Bibliography

Connell, L.D. and Jeffery, R.G., "History matching for optimization of gas drainage from horizontal wells containing sand propped hydraulic fractures," presented to the International Coalbed Methane Symposium, Tuscaloosa, Alabama, May 16-20, 2005.

Dexter, D., "Investigative CBM modeling for horizontal and other well types," presented to the Conference Board of Canada Meeting, Calgary, Feb. 14-15, 2006.

Fan Shengli, "Exploration results and geological analysis of coal-bed gas in the south part of Qinshui basin," Natural Gas Industry, Vol. 21, No. 4, July-August 2001 (in Chinese), pp. 35-38.

Gentzis, T. and Bolen, D., "The use of numerical simulation in predicting coalbed methane producibility from the Gates coals, Alberta Inner Foothills, Canada: comparison with Mannville coal CBM production in the Alberta Syncline," International Journal of Coal Geology, Vol. 74, No. 3-4, May 2008, pp. 215-236.

Hoek, E. and Brown, E. T., "Underground excavation in rock," The Institute of Mining and Metallurgy, London, 1980.

Hoek, E. and Brown, E.T., "Practical estimates of rock mass strength," International Journal of Rock Mechanics and Mining Sciences, Vol. 34, No. 8, December 1997, pp. 1165-1186.

Hoek, E., Carranze-Torres, C., and Corkum, B. "Hoek-Brown failure criterion-2002 edition," presented to the North American Rock Mechanics Society Meeting, Toronto, July 7-10, 2002.

Jiang Da-yuan, "Advances on research of coalbed methane geology in Qinshui Basin," Journal of Chongqing University of Science and Technology, Natural Sciences Edition, Vol. 15, No. 6, 2013, pp. 70-74.

Lin Xiao-yin, "Reservoiring mechanism of coalbed methane in Southern Qinshui Basin," Natural Gas Industry, Vol. 27, No. 8, August 2007 (in Chinese), pp. 8-11.

Meng Zhao-ping, "Characteristics of in-situ stress field in Southern Qinshui Basin and its research significance," Journal of China Coal Society, Vol. 35, No. 6, June 2010, pp. 975-981.

Moschovidis, Z.A., Cameron, J.R., and Palmer, I.D., "Methodology and examples of wellbore stability in coalbed methane wells," International Coalbed Methane Symposium, Tuscaloosa, Alabama, May 16-20, 2005.

The authors

Jie Zhang ([email protected]) is an associate professor and researcher at Southwest Petroleum University, Chengdu, China. His research include wellbore stability, well drilling and coalbed methane development. He holds a PhD in petroleum engineering from Southwest Petroleum University.

Hu Liu ([email protected]) is a postgraduate student at Southwest Petroleum University, Chengdu, China. He studies oil & gas engineering with an emphasis on wellbore stability and well control.

Guanhjie Yuan is a professorate senior engineer an researcher at the Drilling Engineering Institute of the China National Petroleum Corporation. His research interests include reservoirs and coalbed methane development. He holds a PhD engineering from Jiaotong University, Shanghai, China.

Yan Xia is a researcher at the Drilling Engineering Institute of the China National Petroleum Corporation. His research includes drilling and completions. He holds a PhD in engineering from the China University of Petroleum.