Static, dynamic data integration improves reservoir modeling, characterization

Shouxiang M. Ma

Saudi Aramco

Dhahran

Murat M. Zeybek Fikri J. Kuchuk

Schlumberger

Al-Khobar

This article introduces a methodology for reservoir characterization, geological modelling, and well-performance prediction. The methodology integrates petrophysical and pressure-transient data to build a detailed geological reservoir model (RM) with anisotropy.

Detailed petrophysical reservoir characterization, which is critical to reservoir management, consists of data acquisition, data processing, and data distribution in space, or modeling. Data typically include lithology, porosity (φ), water saturation (Sw), zone thickness (h), and permeability (k).

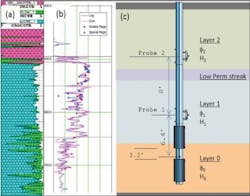

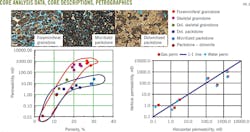

Permeability is the most difficult to characterize. This is especially true in carbonates, such as Saudi Arabia's Arab-D reservoir, due to the heterogeneous pore structure caused by depositional environments and diagenesis, such as dolomitization, compaction, cementation, and fracturing. Fig. 1 shows lithography and porosity typically seen in Arab-D cores and logs.

The most common techniques for in situ reservoir-permeability characterization are based on pressure transient analysis (PTA). This can be analysis of wireline formation testing (WFT), with measurements typically 10-50 ft from the well depending on formation properties, duration of production, and buildup periods. Or, PTA can be performed on date from conventional well testing, with investigation depths from hundreds to thousands of feet.1 2

Generally, a measurement with a deeper depth of investigation has poorer vertical resolution.

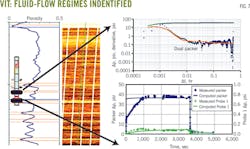

Typically, two WFT modes are used to estimate reservoir permeability: a pretest with probes and a vertical-interference test (VIT) that includes packers and probes (Fig. 1).

A pretest requires a drawdown volume of less than 20 cu cm of fluid, generally mud filtrate. As a result, estimates from a WFT pretest are near-wellbore mobility indicators.

During a VIT, hundreds of liters of reservoir fluid are pumped out at 1-30 b/d for as long as 1 hr. This allows reservoir permeability estimation up to 50 ft into the reservoir, providing a much more comprehensive picture.

Unlike other reservoir petrophysical properties, permeability is directional. Currently, the only techniques that are used routinely for directional reservoir permeability characterization are based on PTA, such as a VIT.3

The RM was validated by comparisons with dynamic data from production logs, downhole pressure tests, and injection-falloff tests. Later it was used in a single-well reservoir simulation to predict well performance, infer in situ reservoir scale reservoir conditions, relative permeability, and capillary pressure.

The methodology was developed in a joint-research project with Saudi Aramco and Schlumberger. Results reported in this article are part of a larger study, some of the details of which have been published previously.4 5

New methodology

In the new methodology, petrophysical properties derived from openhole logs and wireline formation testing (WFT) are calibrated with core-analysis data before being distributed in space to build a geological model.

The established model can be verified from borehole fluid-flow profiles measured by a production log even though layers with no flow or low flow due to skin, low permeability, or low pressure may not be detectable by a production log. See accompanying equations box.

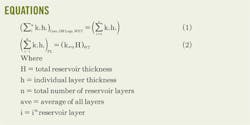

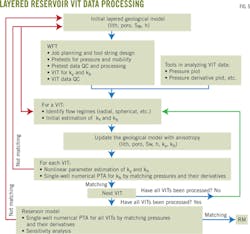

The following summarizes details of the methodology for single-well data integration, reservoir characterization, reservoir modeling, and well-performance prediction (Fig. 2).

Data preparation, integration

Core data are reviewed and quality controlled for geological features (such as depositional environments and layering), lithology, pore types, porosity, permeability, and grain density.

Openhole logs are then reviewed, quality controlled, processed, and interpreted for lithology, porosity, grain density, water saturation, zoning, and zone thickness.

WFT pretest data are reviewed, quality controlled and processed for estimating mobility and then for qualitatively determining permeability.

Together with other geological information, the core data, openhole logs, and WFT pretests are integrated for a foot-by-foot formation evaluation and reservoir characterization.

Geological model

Next, a layered, single-well geological model is generated from the detailed formation evaluation and reservoir characterization.

WFT and VIT data are analyzed to quantify vertical and horizontal permeabilities of the layers selected for the VIT.

The geological model is updated with the vertical and horizontal permeabilities determined from analyses of all VITs.

This layered-anisotropic-geological model is fine-tuned by integrating geological features and the range of permeabilities obtained from performing a single-well numerical PTA-with the pressure and pressure derivatives as the history-matching parameters-for each VIT.

Reservoir model

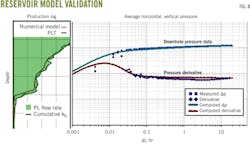

An RM is established by iteratively validating the fine-tuned geological model with Σkh from a production log and the total KavgH from downhole pressure buildup and falloff tests, as shown in our two equations.

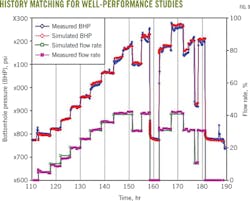

History matching downhole pressure and flow rate allows the RM to be used in a single-well reservoir simulation for well-performance prediction or in any reservoir-characterization and management studies.

Test well application

To test the efficacy of this new methodology, Saudi Aramco drilled a research well, Well-A, in 2001 across the Arab-D carbonate reservoir, acquiring petrophysical data.

Conventional cores were taken from the top 250 ft of the target reservoir. Core description, petrographics, and routine and special core analyses were performed on selected core samples.

Openhole logs acquired included caliper, spectral gamma ray, bulk density, thermal-neutron porosity, sonic, array-induction resistivity, micro-resistivity, resistivity imaging, mineralogy, and nuclear magnetic resonance. Twenty-five WFT pretests and eight VITs were conducted.

Following completion, the well was allowed to produce oil for 1 day to clean out mud invasion. Then, the baseline-flow profile was established from the production log.

The well was shut in to perform a buildup test for total KavgH at connate water saturation (Swc) by using the downhole permanent-pressure gauge just above the top of the tested zone.

After the well was produced, another pressure buildup test was performed immediately before water injection to confirm the determined KavgH at Swc.

During water injection, a stepwise rate change was applied. Each injection rate lasted 3-5 hr, depending on the time required for the electrode-resistivity-array measurement and production-log measurements.

The initial injection rate was 1,000 b/d. At an incremental increase of about 1,000 b/d, the final rate reached 8,200 b/d at the end of the eighth test. A production log was run to obtain the injection profile during each test.

The well was then shut in for a falloff test to determine the total KavgH at remaining oil saturation and skin.

All of the injected water and some oil were produced back to the surface with a nitrogen lift for 14 days. During this period, a production log was frequently run to monitor the fluids produced.

After the well stopped producing water, it was shut in for a final pressure-buildup test to estimate KavgH at a reduced water saturation (similar to, but usually larger than, the original connate water saturation).

Processing, interpretation

Core description and petrographic analysis were conducted to extract information on the reservoir's depositional environment and rock typing and to identify layers.

Conventional core analysis under stress was performed on selected core samples to provide data for log calibration and reservoir layering. On a subset of cores, adjacent twin plugs were taken-one horizontally and another vertically-for permeability measurements. The following, illustrated in Fig. 3, was observed.

1. Correlations between permeability and porosity strongly depend on rock type.

2. The difference between vertical and horizontal permeability is not obvious at the core plug scale. This may be attributed to the following:

• Laboratory permeability measurements can contain uncertainties and the difference between horizontal and vertical permeability at core-plug scale can be chalked up to these.

• To ensure a plug's mechanical integrity, samples are taken in more homogeneous sections where rock anisotropy is less.

• Even though small-scale rock anisotropy can be observed in thin sections, it is probably true that the larger the scale, the more obvious the rock anisotropy.

Logs, WFT presets, VITs

As previously mentioned, a complete suite of openhole logs was run once again. These logs were quality controlled, processed, and interpreted for lithology porosity, and water saturation. Correlations were also used qualitatively to predict reservoir permeability. Use of the processed logs and core data in geological modeling has been previously described and published.5

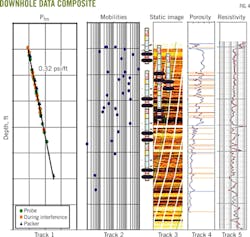

As summarized in Fig. 2, which describes a model built with geological and petrophysical data, 25 pretests were performed with Probe 1 for formation-pressure profiling.

Eight VITs were conducted with a configuration of a dual packer and two observation probes, Probes 1 and 2 (Fig. 1c). Thirteen additional pretests were performed with both probes during the VITs. The use of VITs has been demonstrated to be a powerful tool for characterizing reservoir heterogeneity.1 6-8

A pump-out module was used for fluid withdrawal to create pressure transients in the formation. These were monitored by crystal-quartz pressure gauges and strain gauges at the dual packer and observation probes.

Fig. 4 shows the acquired downhole data, including:

• Track 1-Reservoir pressure (with an oil gradient of 0.32 psi/ft) from the probes, the packer, and during the interference test.

• Track 2-Pretest drawdown mobilities.

• Track 3-Image log and the positions of the VITs.

• Track 4-Reservoir porosity.

• Track 5-Formation resistivity

Reservoir porosity and formation resistivity data provide quantitative information for reservoir layering, while the image log is used to check the reservoir layering.

As shown in Fig. 4, pretest data can be processed for formation pressure and fluid mobilities. Formation pressure derived from the probe pretest is as accurate as that obtained from a packer test or a well test (Track 1). Therefore, it is routinely used for reservoir-fluid typing, fluid-contacts identification, and free-water-level determination.

On the other hand, the probe pretest drawdown mobility is rather qualitative, due to its small volume drawdown (typically 5-20 cu cm). It has a shallow depth of investigation, and it is affected by formation damage in the invaded zone and by near-wellbore, small-scale heterogeneity.

Because of the small volume drawdown, the mobility determined typically does not include anisotropy. Consequently, pretest drawdown mobility can only be qualitatively used for reservoir rock and fluid characterization.

As described in Fig. 2, VIT data can be processed for reservoir rock anisotropy assessment. This VIT data processing workflow is expanded in Fig. 5. Processing the VIT data requires a robust geological model to match the packer's and probe's pressures and pressure derivatives, with predicted vertical and horizontal permeability. Because this matching is for all VITs, an iterative process is necessary.

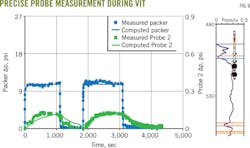

In a heterogeneous reservoir, pressure changes at the observation probes-especially the one with the farthest spacing-may be very small. A successful VIT in this situation, requires verry-high-precision pressure gauges (Fig. 6).

In addition to determining vertical and horizontal permeability, as described in Fig. 5, VITs also can be useful in reservoir-fluid-flow-regime identification and detailed reservoir heterogeneity characterization.

Examining the pressure and its derivative vs. buildup time, as we have in Figs. 6 and 7, reveals the following:

• Probe pressure changes of 0.1 psi are observed repeatedly with the high-resolution crystal quartz gauges.

• Measured packer and probe pressures are matched or reproduced satisfactorily with the geological model.

• Fluid-flow regimes are identified from features of buildup-pressure derivatives. The identified flow regime is consistent with the geological model.

Final reservoir model

Integration of geological information with data derived from core description and core analysis, openhole logs, WFT pretests and VITs established the RM in Test Well A, following the methodology described in Fig. 2 and shown in Table 1. This model is considered accurate because it integrates all relevant data and, more importantly, because it is internally consistent with VIT pressure and pressure derivatives.

The established RM is further validated in terms of its production behaviors by comparing its data with the fluid-flow profile derived from production logs, and the total KavgH derived from numerical analyses of well-test pressure and pressure derivative. Results show that the model matches the well's dynamic behavior very closely (Fig. 8).

As shown in Fig. 9, the RM can be used in well-performance studies by matching and predicting the bottomhole pressure and flow rate. It has also been used in Test Well A for:

• Identifying and characterizing reservoir heterogeneity.

• Inverting reservoir scale and reservoir condition relative to permeability and capillary pressure.

• Assessing oil recovery by waterflooding.

• Monitoring water movement in situ in connection with measurements of a specially designed electrode-resistivity array and permanent downhole pressure gauges.4 5

Acknowledgements

The authors would like to thank the management of Saudi Aramco and Schlumberger for their permission to publish this article.

References

1. Ayan, C., Hafez, H., Hurst, S., Kuchuk, F.J., O'Callaghan, A., Peffer, J., et al., "Characterizing Permeability with Formation Testers," Oilfield Review, Vol. 13, No. 3, October 2001, pp. 2-23.

2. Kuchuk, F.J., "Radius of Investigation for Reserve Estimation from Pressure Transient Well Tests," presented to the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, Mar. 15-18, 2009.

3. Onur, M., and Kuchuk, F.J., "Nonlinear Regression Analysis of Well Test Pressure Data with Uncertain Variance," presented to the SPE Annual Technical Conference and Exhibition, Dallas, Oct. 1-4, 2000.

4. Kuchuk, F.J., Zhan, L., Ma, S.M., Al-Shahri, A.M., Ramakrishnan, T.S., Altundas, B., et al., "Determination of In-Situ Two-Phase Flow Properties through Downhole Fluid Movement Monitoring," SPE Reservoir Evauation and Engineering, Vol 13, No. 1, 2010, pp. 575-587.

5. Zhan, L., Kuchuk, F.J., Al-Shahri, A.S., Ma, S.M., Ramakrishnan, T.S., Altundas, B., et al., "Characterization of Reservoir Heterogeneity through Fluid Movement Monitoring with Deep Electromagnetic and Pressure Measurements," SPE Reservoir Evaluation & Engineering, Vol. 13, No. 3, June 2010, pp. 509-522.

6. Kuchuk, F.J., "Pressure Behavior of the MDT Packer Module and DST in Crossflow-Multilayer Reservoirs," Journal of Petroleum Science and Engineering, Vol. 11, No. 2, June 1994, pp. 123-135.

7. Kuchuk, F.J., Halford, F., Hafez, H., and Zeybek, M., "The Use of Vertical Interference Testing to Improve Reservoir Characterization," presented to the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, Oct. 13-15, 2000.

8. Zeybek, M., Kuchuk, F.J., and Haez, H., "Fault and Fracture Characterization Using 3D Interval Pressure Transient Tests," presented to the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, Oct. 13-16, 2002.

Based on a paper presented to the SPE Annual Technical Conference and Exhibition, New Orleans, Sept. 30 - Oct. 2, 2013.

The authors

Shouxiang M. Ma ([email protected]) is a senior petrophysical consultant in Saudi Aramco's reservoir description division. He holds a BS from the China University of Petroleum, Shandong, and an MS and PhD from the New Mexico Institute of Mining and Technology, Socorro, all in petroleum engineering. Ma is a member of the Society of Core Analysts and the Society of Petroleum Engineers (SPE).

Murat M. Zeybek ([email protected]) is a reservoir engineering advisor and reservoir and production domain champion for Schlumberger's Middle East region. He holds a BS from the Technical University of Istanbul and an MS and PhD from the University of Southern California, Los Angeles, all in petroleum engineering. Zeybek is a member of SPE.

Fikri J. Kuchuk ([email protected]), a Schlumberger fellow, is currently chief reservoir engineer for the company's testing services. He holds a BS from the Technical University of Istanbul, and an MS and PhD from Stanford University, Palo Alto, Calif., all in petroleum engineering. Kuchuk is a member of SPE, the Society for Industrial and Applied Mathematics, the Russian Academy of Natural Sciences, and the American National Academy of Engineering.