Combined methods sharply drop storage evaporation

Carlos Cruz

Iturri Group

Seville, Spain

Straight-forward preventative measures can reduce evaporative losses from tanks by 95%, with attendant economic and environmental benefits. Reducing evaporation also helps preserve product quality and reduces fire risk. This article studies the major variables affecting evaporative loss. Wind is a key variable, while ambient temperature is not.

All stored liquid has a vapor pressure, which determines evaporation depending on the surface temperature and the composition of the liquid. Under static conditions, the liquid's vapor pressure establishes a balance in the vapor concentration, after which no further evaporation occurs. Petroleum storage tanks, however, are exposed to dynamic conditions—temperature, pressure, and wind speed—that break this balance, causing continuous evaporation.

The American Petroleum Institute (API) defines two types of losses for a floating-roof tank: standing loss and working loss. Standing loss consists of losses due to the evaporation of stored product that occur without varying the level of the liquid in the tank. It is the sum of losses due to the seal issues, deck fittings, and plate unions on floating decks comprised of screwed plates. Standing loss encompasses most losses by evaporation in floating roof tanks (EFRT) and is determined primarily by temperature and wind as well as tank configuration and type of product stored. Working loss, caused by product that adheres to the walls and evaporates when exposed to the atmosphere, is relatively minor in comparison.

Evaporative loss through seal mechanisms is complex. This article demonstrates that wind is the dominant factor in causing EFRT, the difference in pressure and flows of air formed through the external floating roof causing the evaporation. The magnitude of wind losses depends on the seal and the presence of any gap between the seal and the shell. Expansion of the vapor in the area under the seal, attributable to changes in temperature, pressure, or both, is another EFRT mechanism.

Deck fittings passing through the floating roof are another source of potential loss because they have openings allowing stored vapor to flow from the liquid to the atmosphere.

Variables study

Studying the impact of the different variables present in the evaporation of the product in a tank centered on calculating losses by evaporation with different configurations of tanks in different Spanish cities. Researchers used a mathematical model using emission factors published by the US Environmental Protection Agency (EPA) in Section 7.1 "Organic Liquid Storage Tanks." They then checked the result of this theoretical model by measuring the energy balance of the tanks themselves.

The most important variables were:

- Ambient temperature.

- Wind speed.

- Tank type.

- Type of seal.

- Stored product.

- Paint color.

Tank volume also affects evaporation, but to simplify the study, and since it is obvious that it will directly correlate with evaporation volumes, it was held constant.

Location effect

Studying location's effects, or the effect of the average ambient temperature, solar irradiance, and wind speed in the various cities where the tanks are installed, required tank type and volume be held constant. The tank studied in each setting is an external floating roof tank, 80 m in diameter and 17 m high, with the walls painted white, containing RVP 10 gasoline, with a mechanical primary seal and no secondary seal (Table 1).

The Pearson coefficient of correlation—a coefficient (r) between 0 and 1 measuring the degree of relationship between two variables, where 0 indicates that there is no correlation and 1 indicates that there is a perfect correlation—allowed study of each variable's influence on total losses by evaporation. Ambient temperature is the average surface temperature of the liquid, TL, which largely depends on the average ambient daily temperature, TAA, and the daily average temperature of the stored liquid, TB, and to a lesser extent solar irradiance, I. α is a coefficient that depends on the tank's paint color. Average surface temperature: TL= 0.44TAA + 0.56TB + 0.0079αI.

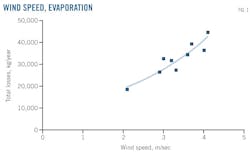

Liquid surface temperature and irradiance have minor correlation indices; 0.24 and 0.14, respectively. Wind speed, however, has an r = 0.92 correlation rate (Fig. 1). Keeping location constant as Huelva and using these correlations allows study of the remaining variables; tank type and seal type.

Tank type

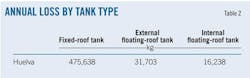

Researchers studied three types of tanks: fixed roof, external floating roof, and internal floating roof. Fixed roof tanks have the greatest evaporation losses (Table 2). The tank's paint color, however, greatly influences these losses. The solar absorption coefficient (α) of a tank shell, depends on the color of the paint, with a correlation coefficient r=0.99.

Seal type

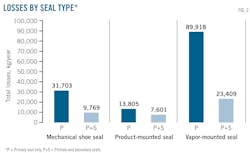

Seal study examined three types—mechanical shoe seal, product-mounted seal, and vapour mounted seal—and two configurations for each type of seal; primary only and primary plus secondary. Fig. 2 shows the respective losses for each.

Evaporation reduction

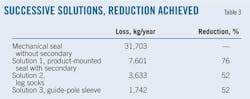

The Huelva example uses a mechanical shoe seal without a secondary seal, resulting in losses of 31,703 kg/year, 81% of which were caused by seal type. Installing a product-mounted seal with a secondary seal reduced total loss by 76%, to 7,601 kg/year.

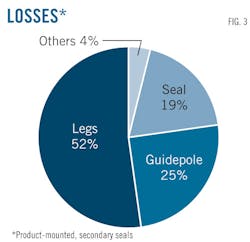

Having improved seal efficiency, proposals focused next on reducing losses caused by the floating roof's legs (52%). Installing leg socks (polyurethane covers) closed the gap between the leg and the roof, reducing losses an additional 52%, to 3,663 kg/year (Fig. 3). Applying similar covers to the tank's tube guide reduced evaporation losses still further.

Applying these three measures reduced total evaporative losses by 95%, from 31,703 kg/year to 1,742 kg/year (Table 3).

References

1. American Petroleum Institute, "Manual of Petroleum Measurement Standards," Chapter 19.2, Evaporative Loss from Floating-Roof Tanks, 2011.

2. American Petroleum Institute, "Manual of Petroleum Measurement Standards," Chapter 19.1, Evaporative Loss from Fixed-Roof Tanks, 2011.

3. US Environmental Protection Agency, AP-42 – "Compilation of Air Pollutant Emission Factors," Section 7.1 – Organic Liquid Storage Tanks, September 2006.

4. Gord, M.F., Nabati, A., Targhi, M.S., and Rasekh, A., "Effect of Rim Seal on Evaporation Loss from Khark Island Storage Tanks," Journal of Petroleum & Environmental Biotechnology, Vol. 1, No. 2., Oct. 28, 2010.

5. Wongwises, S., Rattanaprayura, I., and Chanchaona, S., "An Evaluation of Evaporative Emissions of Gasoline from Storage Sites and Service Stations," International Journal of Science Technology, Vol. 2, No. 2, July 1997.

6. US Environmental Protection Agency, "VOC Emissions From Volatile Organic Liquid Storage Tanks," Background Information For Proposed Standards, EPA-450/3-81-003a, July 1984.

The author

Carlos Cruz ([email protected]) is product manager for oil and gas at Iturri Group, Seville, Spain. He has also served as energy efficiency engineer at other companies in the sector. He holds an MS in industrial engineering (2011) from the Higher School of Engineering, University of Seville.