China developing strategy for horizontal fracturing technology

Zhao Jinzhou

Yang Hai

Li Yongming

Southwest Petroleum University

Chengdu City, China

Although China's need for both crude oil and natural resources has increased dramatically during the last decade, its productivity lags behind.

In 2005, China's production was only 3.1 tonnes/day (tpd)/well (22.32 b/d), which is a third of the world average. During 2012, China's oil and gas consumption reached 0.492 billion tonnes and 144.6 billion cu m, respectively. The 2012 production, however, was 0.207 billion tonnes of oil and 106.71 billion cu m of natural gas.

China must rely on imports for nearly 57.8% of the oil and 28.2% for the gas needed.1 2 In 2013, China will need 0.61 billion tonnes oil, which poses a serious challenge for the Chinese government; in 2015, 230 billion cu m of gas will be needed.2

According to the US Energy Information Administration (EIA), China's shale gas resource is 100 trillion cu m and the recoverable shale gas resource is 36 trillion cu m. China's Twelfth Five-Year Plan on Natural Gas Resources reports that China's recoverable shale gas is 25 trillion cu m. The shallow (<2,000 m) coalbed methane reserve is about 36.8 trillion cu m; the recoverable reserve is 10.8 trillion cu m.4

Reasonable and effective development of shale gas reservoirs would alleviate market stresses and reduce the portion of energy imported. China's output of shale gas will increase to 6.5 billion cu m/year by 2015.5

Between 2006 and 2010, China invested 278.8 billion yuan (about $44 billion) in exploitation and development of oil and gas reservoirs and attained a production of 0.2 billion tonnes/year (tpy) of oil and 94.2 billion cu m/year (bcmy) of natural gas.6 Evaluation of national oil and gas resources in 2010 indicated that crude oil production will be 0.36 billion tpy in 2015, 0.41 billion tpy in 2020, and 0.45 billion tpy in 2030. Furthermore, five oil and gas areas, each with production capacity of 50 million tpy, would be established by late 2015.7

Between 2011 and 2015, China expects to increase proved conventional gas reserves by 3.5 trillion cu m; the recoverable reserve is 1.9 trillion cu m. The incremental reserve of proved coalbed methane is expected to reach 1 trillion cu m.3 Meanwhile, China can provide 176 billion cu m of gas in 2015 domestically, including 138.5 billion cu m of conventional gas, 6.5 billion cu m of shale gas; China will import 93.5 billion cu m of gas under current contracts.

Horizontal fracturing technologies (HFTs) have enabled China to increase its energy resources productivity and relieve the intense domestic energy stress. In November 2012, the Ministry of Land and Resources of China reported that compared with 2007, China's geological oil reserves were 93.9 billion tonnes in 2012 (representing an increase of 22.7%) and 54.6 trillion cu m geological gas reserves (representing a 55.8% increase).

In 2012, China National Petroleum Corp. (CNPC) oil production reached 0.11 billion tonnes, which is an increase of 2.791 million from 2011's production. Moreover, CNPC completed 15,890 new wells (including 1,351 domestic horizontal wells) and completed 350 horizontal wells overseas (including exploration, appraisal, and production wells).2

HFTs development

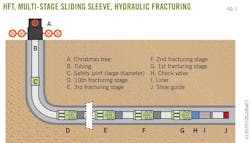

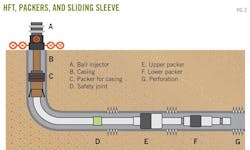

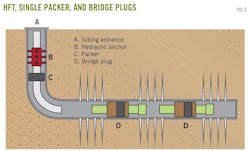

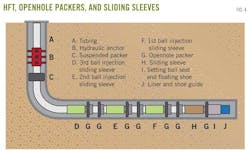

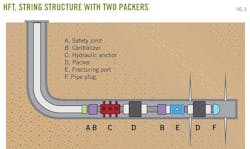

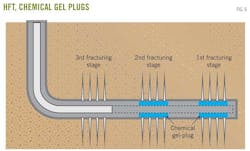

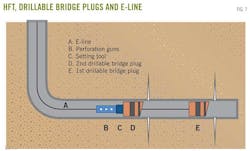

Figs. 1-7 show the current status of HFT development in China.

In 2006, CNPC initiated a 5-year program for the industrial application of HFTs for low-permeability reservoirs. In 2011, the average production of a single stimulated horizontal well was 3.9 times that of a vertical well. By the end of 2011, staged HFTs had enabled CNPC to complete a total of 4,722 stages for 1,133 wells in low-permeability reservoirs, eliminating the need for 3,000 vertical wells and more than 6.67 sq km (2.57 sq miles) of land.2

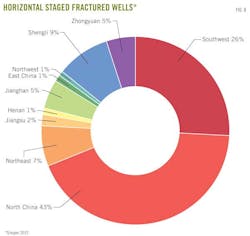

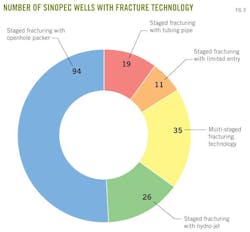

Fig. 8 illustrates the distribution of 185 Sinopec Corp. staged fractured wells in April 2012.8 Fig. 9 shows the different fracturing techniques applied in the 185 Sinopec wells.

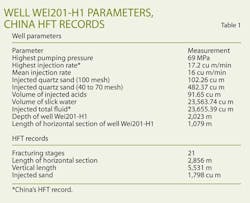

The first horizontal shale gas well in China, Wei201-H1, was successfully stimulated in July 2011. Table 1 lists the primary parameters of Wei201-H1 and records set in China's horizontal wells. Well Wei201-H1 started production in August 2011 with a 10,000 cu m/day capacity.9 10

To the present, 62 shale gas reservoir appraisal wells, including 14 horizontal wells, have been finished in China. Gas flow was obtained from 24 wells; so far, the longest horizontal section of a shale gas well is 1,500 m.6

During the last 5 years, Chinese oil companies have optimized HFTs and classified them into three core technology groups:

1. Staged fracturing technology with two packers.

2. Horizontal staged fracturing technology with sliding sleeve.

3. Staged fracturing technology with hydro-jet and sand.

In the meantime, Chinese oil companies have promoted several techniques, including hydraulic fracture monitoring and evaluation, workover of horizontal wells, and staged fracturing stimulation with liquid gel-plug. These techniques have been applied in 508 horizontal wells, and maintained an average production of 6.5 tpd/well.2

Currently, HFTs can meet the basic need for the development of low-permeability reservoirs in China.

Daqing, Changqing, and Jilin fields show case the current HFT research and application level in China. Fig. 10 shows the location of the three fields.

Daqing field

In November 2012, China's Ministry of Land and Resources reported that oil production from Daqing field will reach 40 million tpy and increase by 32-35 million tpy until 2030. In 2012, Daqing oilfield produced 40 million tonnes of oil and 3.3 billion cu m of gas.2

The poor geological features of Daqing field have restricted development of vertical wells. The permeability ranges from 0.01 to 0.5 md, the hydrocarbons in place cover 100,000-200,000 tonnes/sq km, and the layer thickness is only 0.5 m.11

Since 2006, Daqing field has worked toward technological breakthroughs in staged HFT. Various HFTs have been applied in large-scale practice, including HFT with two packers supplemented by limited-entry perforating, mechanical plugs, liquid gel-plugs, and hydraulic sandblasting techniques.

In May 2012, horizontal well Da165-94-ping116, was successfully stimulated with controllable transverse fracturing technology and is currently producing without artificial lift. In this area, the reserves are abundant, both horizontally and vertically, and the pores are interconnected. The controllable transverse fracturing technique works well in this area.

In recent years, 103 wells have been drilled in the testing area, 22 of which will be stimulated in the following months. The controllable transverse fracturing can increase production by five times that of ordinary techniques.2

To date, 229 horizontal wells with 1,328 stages have been completed in Daqing. The current average production of single horizontal wells is 4.6 tpd, which is 4.4 times that of nearby vertical wells.

Changqing field

The exploration area of Changqing field, primarily in Ordos basin, covers 0.37 million sq km. The total oil and gas resources of this field are 12.85 billion tonnes and 15 trillion cu m, respectively. Characteristics of this field include low permeability, low pressure, and low hydrocarbons in place; HFT provides the most promising technology to address these issues.

In 2012, Changqing field produced 22.31 million tonnes of oil and 28.54 billion cu m of gas. During the last decade, it has produced a total of 0.425 billion tonnes of oil.2

Since 2005, Changqing field applied two effective of HFTs to meet the need of low-permeable reservoirs: a technique using hydraulic sandblasting combined with small packers and continuous fluids mixing and a multi-cluster staged hydraulic sandblasting.

Since 2010, 54 of the 93 horizontal wells have been completed and put into production. The daily crude oil production has increased to 3.5 times that of the vertical wells. Natural gas production has increased to 5 times that of the vertical wells.

In October 2011, to increase the production of single wells with ultralow permeability, researchers began to focus on the simultaneous fracturing of multiple wells with the multicluster staged fracturing technique. They have completed the fracturing treatment of the second stage in the test.

By the end of January 2012, 165 fractured oil wells were completed, with 939 stages stimulated with the hydraulic staged sandblasting fracturing technology. Oil production of these wells was 5.29 tpd. During the same time, 73 fractured gas wells were completed, and 260 stages were stimulated. Gas production for these wells reached 61,000 cu m/day. As compared with the vertical wells, it increased by 179,000 tonnes of oil and 1.48 billion cu m of gas and earned an additional 0.65 billion yuan ($0.105 billion).2

Based on China's empirical stimulation method of "10 cu m pumping rate, 1,000 cu m of ceramsite, and 10,000 cu m of liquids," the An'ping-X well was stimulated with a pumping rate as high as 12 cu m/min by the end of July 2012. This strategy used a new fracturing pattern that included a long horizontal section, low sand concentration, high pumping rate, large volumes of liquid, and multi-staged treatments.

By yearend 2012, 143 horizontal wells were completed. The average production was 8.3 tpd of oil, which is 4.1 times the production of nearby vertical wells.2

Jilin field

By yearend 2012, 104 horizontal wells were put into production in Jilin oilfield. The field plan included replacing 600 vertical wells with 205 horizontal wells, which is the total number of horizontal wells drilled in this field during the last 7 years.

As planned, the single well oil production expected is 7.2 tpd, and the crude oil production expected is 5.8 million tpy, which represents a large portion of Jilin field hydrocarbon production of 7.8 million tonnes.2

After 5 years of research, three kinds of core HFTs have been developed to address specific conditions at Jilin. An annulus fracturing technology was developed to use with high pumping rates, and a compressed sliding-sleeve staged fracturing technology was developed to use with high-temperature, high-pressure conditions; a compression double take-up packer staged fracturing technology was developed for shallow oil reservoirs.12

Pay zones at Jilin oilfield can now be separated into 20 stages with permanent packers; the production stage is optional and managed with controllable sliding-sleeve staged fracturing technology. Based on the layer heterogeneity determined by geological analysis, researchers have also developed a new system of multicluster staged fracturing technology with advanced fracturing string recycle technique. This system can be used to optimize the number of clusters and cluster spacing and to recycle the fracturing string easily.2

Moreover, three kinds of packers have been developed for this field: openhole, anchoring, and suspended. Three completion systems were also developed: 7-in. casing and 4.5-in. liner; 5.5-in. casing and 3.5-in. liner; and 5.5-in. cased completion. These systems can address fracturing requirements for openhole horizontal wells with temperatures of up to 150° C. and pressure differentials to 70 MPa.

Jilin field has developed a comprehensive, efficient, and safe fracturing operation system that uses geological models of horizontal wells, as well as simulation and prediction of geostress fields. The field also uses continuous sand and liquid supply and surface fracturing operations.

In July 2012, Well X (located in Zone Su36-11) became the first horizontal well in China with 10 stages stimulated by fracturing with the immobile strings technique. In August, an openhole horizontal well in a tight oil reservoir was successfully stimulated, with 21 stages, 9,770 cu m of fracturing fluids, and 1,015 cu m of ceramsite.7

Table 2 lists the costs associated with the mechanical staged horizontal fracturing technique.

To date, a total of 243 wells and 637 stages have been completed with staged fracturing techniques with sliding-sleeve and immobile strings at Jilin field.

In first-half 2012, the annulus recyclable multicluster staged fracturing technique was applied at Well Hei-H-ping-2. A total of 15 stages and 34 clusters were completed. After application of the annulus multicluster stage fracturing technique, the well's production was 25 tpd of liquids and 10 tpd of oil. The success of Well Hei-H-ping-2 indicates that the large-scale horizontal fracturing technology is safe, fast, and controllable. It also created a new record of the largest number of stages and clusters with a single trip downhole.2

The breakthrough of HFTs enabled Jilin field to recover 500 million tonnes of oil from low-permeability reservoirs and from pay zones beneath urban areas or villages.

Goals, strategies

China has established several goals and strategies to continue its petroleum industry advancements.

One of the goals is to continue advancing the research and development of microseismic monitoring technology for horizontal wells.13 This effort includes continuing to research monitoring techniques of the fracturing process and developing accurate methods of predicting parameters of hydraulic and natural fractures. The analysis develops analogs that can be used for completing new wells.

China also plans to accelerate the pace of microseismic equipment research and development to obtain reliable and easily processed data and to develop permanent seismic geophones for receiving fluid flow information at an early stage. This effort will enable technologists to recognize flow patterns, barriers, and fault sealing ability.

Another focus of this goal includes developing a comprehensive analytic method to combine data from microseismic, active seismic, logging, geophysical exploration, and reservoir engineering. A fundamental part of this goal includes intensifying educational efforts and publicity for the microseismic monitoring technique.

China also plans to intensify its efforts to improve offshore fracturing operation systems.14 Components of this goal include continuing to study seawater-based, high-temperature-tolerant offshore fracturing fluids technology and developing continuous mixing facilities for fracture fluids. China also plans to research integrated-string perforation techniques, well testing, fracturing, and production operations, as well as to accelerate the pace of design and construction of fracturing ships.

And China plans to improve HFT optimization15 by focusing on forecasting production of horizontal wells and by developing commercial horizontal fracturing software for staged fracturing designs. This software will be based on fracture interference, fracturing spacing, and fracture position. Attaining this goal also includes promoting a better understanding and recognition of fracture patterns and researching their optimization methods.

China also will work toward developing a set of norms for the optimized design of single horizontal wells, as well as integrating exploration and development with hydraulic fracturing monitoring and evaluation techniques.

Another goal includes performing more in-depth studies of fundamental horizontal well theories.15 This goal includes advancing the application of physical and numerical simulation in horizontal well research, as well as strengthening the research on well trajectory design, stress profiles, fracture geometry, and fracture initiation and propagation mechanisms of horizontal wells.

And China will accelerate the pace of development of multicluster staged fracturing techniques. Currently, China's multicluster staged fracturing technology is still in early development. Only a few horizontal wells were stimulated with this technique. Moreover, most of the parameters, including perforation parameters, number of clusters, and cluster spacing, were based on foreign cases. Technical personnel will be encouraged to learn and study the fundamental theories to spread and apply this innovative technology.

Another strategy that China will use to continue its petroleum industry advancements focuses on promoting the drilling and completion techniques for horizontal wells. To implement this strategy, China will optimize the completion methods for various reservoirs to avoid the mismatches between completion and fracturing strings. It will also quicken the pace of improving cementing techniques to ensure the effectiveness of packers. This strategy also includes avoiding damage to the reservoir during drilling to build an environmentally friendly operation system.

China also plans to reinforce research and development of fracturing tools, equipment, and materials. This goal includes developing large-scale gas turbine engine, natural gas compressor, and large-scale LNG low-temperature pumps domestically, as well as developing inflatable packer rubber with small outside diameter and high swelling ratio to reduce the risk of damage. The outside diameter of the packer will also be reduced to enable easier tripping operations and to reduce the risk of jamming from sand.

This plan also includes designing a new type of sand blaster; the drainage structure of the present blaster and its mechanical spring will cause the shear failure of fracturing fluids, and the proppants will damage the pipes.

Another component of this research and development includes reducing the number of tripping times and operational risk by using an integrated fracturing production pipe string. In the meantime, China will implement three processes to continue working toward the development of viscoelastic surfactant (VES) fracturing fluids.

First, China will attempt to reduce the cost to less than 2,000 yuan/cu m from 4,000 yuan/cu m and promote large-scale applications. Secondly, it will initiate an intensive study of the influence mechanisms of temperature, pressure, and total dissolved solids (TDS) on rheological properties of VES, particularly the temperature-resistance evaluation. Third, nanotechnology will be included in VES research because of its unique surface features, which can be used as gel breaker.

China also plans to strengthen international cooperation in HFT by increasing the scope, channels, and forms of international cooperation. This goal will also focus on strengthening exchanges and cooperation with foreign petroleum institutes, scientific research institutes, and energy enterprises.

Another component of China's goals includes applying HFTs in large-scale shale resources development. China plans to meet this goal by increasing the pace of research and application of state-of-the-art techniques for the large-scale development of shale gas resources to reduce the cost of shale gas horizontal wells. Currently, the cost to complete a horizontal shale gas well in China is $1.5 million or more.

The Apollo Project of CNPC2 is also part of China's goals and strategies. It will focus on expanding studies of reservoir engineering for horizontal wells in low-permeability reservoirs and enhancing the capability of uniform acidizing stimulation for the entire well.

This project will also continue development of staged fracturing technology with mechanical plugs for horizontal wells in Jilin field's low-permeability reservoirs, as well as accelerate the improvements of comprehensive techniques using staged fracturing technology with multiple hydra-jet, mechanical plugs, and acidizing with coiled tubing.

Acknowledgment

This paper was supported by Sichuan Provincial Youth Science and Technology Fund, Program for New Century Excellent Talents in University, and Innovation Foundation of CNPC.

References

1. National Energy Administration (www.nea.gov.cn).

2. China National Petroleum Corporation (www.cnpc.com.cn).

3. National Development and Reform Commission (www.sdpc.gov.cn).

4. Twelfth Five-Year Plan on Natural Gas Resources. December 2012, released by National Development and Reform Commission (www.sdpc.gov.cn).

5. White Paper on China's Energy Policy 2012, October 2012, released by the State Council Information Office of the People's Republic of China (www.scio.gov.cn).

6. Ministry of Land and Resources of the People's Republic of China (www.mlr.gov.cn).

7. Dynamic Evaluation of National Oil and Gas Resources 2010, released by National Energy Administration, November 2011 (www.nea.gov.cn).

8. China Petroleum & Chemical Corporation (www. sinopecgroup.com).

9. Yue, Yuan, "1st Horizontal Shale Gas Well has been Put into Production," Oil and Gas Treating and Processing. Vol. 29, No. 5, August 2011.

10. International Energy (www.in-en.com).

11. Production Engineering Research Institute of Daqing Oilfields (dqyt.cnpc.com.cn).

12. National Oil & Gas Exploration and Development Corp. cnodc.cnpc.com.cn.

13. Bing, Liang, "Micro-seismic Monitoring Technique Applied in Oil & Gas Exploration and Development," Beijing: Petroleum Industry Press, 2004.

14. Reports of 6th International Symposium "Advanced Theory and New Technologies of Unconventional Reservoir Exploitation and Development held in Southwest Petroleum University," Nov. 1-2, 2012; www.swpu.edu.cn.

15. Zongtian, Li, "Prospect of Horizontal Well Fracturing Technology," Oil Drilling & Production Technology, Vol. 31, No. 6, December 2009.

Manuscripts welcomeOil & Gas Journal welcomes for publication consideration manuscripts about exploration and development, drilling, production, pipelines, LNG, and processing (refining, petrochemicals, and gas processing). These may be highly technical or they may be more analytical by way of examining oil and natural gas supply, demand, and markets. OGJ accepts exclusive articles as well as manuscripts adapted from oral and poster presentations. An Author Guide is available at www.ogj.com, click "home" then "Submit an article." Or, contact the Chief Technology Editor ([email protected]; 713/963-6230; or, fax 713/963-6282), Oil & Gas Journal, 1455 West Loop South, Suite 400, Houston TX 77027 USA. |

The authors

Zhao Jinzhou ([email protected]) is vice-president of Southwest Petroleum University (SWPU) and a researcher in State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU in Chengdu, China. He is director of China Petroleum Education Society and Chinese Society of Petroleum Graduate Education, a member of National Technical Committee of Oil and Gas Reservoir Exploitation and Society of Petroleum Engineers. Zhao holds an MS (1985) in oil and gas reservoir exploitation engineering from SWPU, Chengdu, China.

Yang Hai ([email protected]) is a PhD candidate of Southwest Petroleum University at State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU, Chengdu, China.

Li Yongming ([email protected]) is a professor of SWPU and a researcher in State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation of SWPU. His work is supported by Ministry of Education. He holds a PhD (2003) from SWPU.