Clean Fuels Project will reshape the refining industry in Kuwait

Kuwait's Clean Fuels Project (CFP) will reconfigure the country's three refineries and, in conjunction with grassroots construction planned at Al Zour, nearly double total refining capacity to 1.4 million b/d.

Under the CFP, Kuwait National Petroleum Co. will integrate and upgrade the 270,000-b/d Mina Abdullah and 466,000-b/d Mina Al Ahmadi refineries and close the 200,000-b/d refinery at Shuaiba. The newly integrated refineries will operate as a merchant complex with total capacity of about 800,000 b/d. Capacity of the new refinery at Al Zour in southern Kuwait, which will mainly supply low-sulfur fuel to Kuwaiti power plants and yield products for export, will be 615,000 b/d.

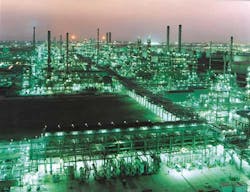

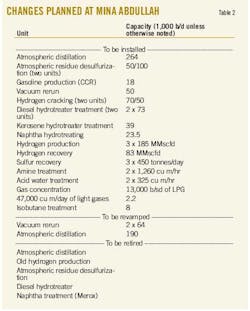

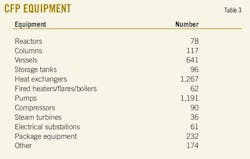

The CFP includes the installation of 39 units, revamping of 7 units, and retirement of 7 units (see tables). Construction is to begin in December and be complete in December 2017.

KNPC will close the Shuaiba refinery after start-up of the Al Zour facility, planning for which was suspended between 2009 and 2011 because of political opposition.

According to KNPC, a study of the Shuaiba refinery determined that a revamp would be uneconomic. After closure, Shuaiba's storage and marine export facilities will be incorporated into the CFP. Reuse of some of the refinery's units and equipment is under study.

After completion of the CFP, the reconfigured Mina Abdulla and Mina Al Ahmadi complex will produce gasoline with no more than 10 ppm sulfur, compared with 500 ppm now. Benzene and aromatics concentrations also will decline.

The CFP will lower gas oil sulfur content to as low as 10 ppm, depending on destination. The facilities now produce gas oil with 500-5,000 ppm sulfur. Bunker fuel oil sulfur content will drop to 1 ppm from 4.5 ppm now. Maximum sulfur content of full-range naphtha will drop to 500 ppm from 700 ppm.

Kuwaiti refining

The existing refineries occupy adjacent sites on the Kuwaiti coast, 50-60 km south of Kuwait City, with Mina Al Ahmadi on the north, Mina Abdullah on the south, and Shuaiba in between.

Shuaiba is the newest. The refinery started up in 1968, heralded as the world's first all-hydrogen refinery (OGJ, Dec. 23, 1968, p. 41).

Key processing capacities at Shuaiba, which has a single crude and vacuum unit, are 15,800 b/d of catalytic reforming, 46,000 b/d of isocracking (first-stage hydrocracking), 36,000 b/d isomax (second-stage hydrocracking), and 54,000 b/d of H-Oil hydrocracking. The refinery has three steam-methane reforming units, each able to produce 74 MMscfd of 95% pure hydrogen.

Kuwait's oldest refinery is Mina Al-Ahmadi, commissioned in 1949. Its main processing units are for naphtha reforming, two with capacities of 35,000 b/d each; hydrocracking, 40,000 b/d; and fluid catalytic cracking, 40,000 b/d. An LPG plant at Mina Al Ahmadi has three trains able to process 560 MMscfd each of natural gas and condensate produced in Kuwait oil fields and refinery gases. Mina Al Ahmadi has three crude units.

The Mina Abdullah refinery, built in 1958, has two crude units and a delayed coker with two identical trains and total capacity of 76,000 b/d. Coke from Mina Abdullah is exported from the port at Shuaiba.

All three of Kuwait's refineries sustained heavy damage at the end of the Iraqi occupation of 1990-91 and required extensive reconstruction (OGJ, Mar. 15, 1993, p. 48).