Automation maximizes performance for shale wells

Bob Sherven

Shell International Exploration & Production Inc.

Houston

David Mudry

Vinson Process Controls

Dallas

Al Majek

Emerson

Houston

Although automation technology has been used for many years to improve well performance in oil and gas production, the technology continues to evolve, benefitting both operations and production.

Large drilling programs in the shale plays of North America have created many free-flowing wells. Maintaining optimal performance for so many sites can prove difficult for any production group.

Control system

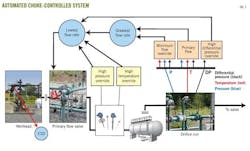

In the northern Louisiana portion of the Haynesville shale play, Shell International Exploration & Production Inc. has met with success in controlling the free-flow stage of well lifecycles. Each well is equipped with the control system shown in Fig. 1. Flow from a well is manipulated with a single automated choke valve.

Measurements taken to obtain this control include delta pressure (DP) and flow rate from an orifice run feeding a sales pipeline, and static pressure and temperature of the flowline feeding a separator.

Several requirements had to be met to obtain the degree of control needed. The electronic platform must include customized proportional-integral-derivative (PID) control loops and coded algorithms; it must also be capable of performing American Gas Association style flow computations and communicating with an existing supervisory control and data acquisition (scada) system. The units must be rugged enough for harsh environments and, because of the lack of electrical power in the area, capable of functioning on a solar-powered system (Fig. 2).

For this application, Shell selected the Emerson Remote Operations Controller (ROC) 800 series of equipment. Production Manager, a software product of Vinson Process Controls, provides the user interface and enables operators to access and modify the system.

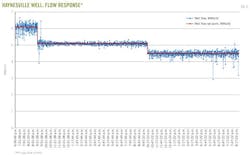

The primary focus of the system (Fig. 3) is to maintain a steady flow from the well to the sales line, based on an operator-specified set point. Multiple overrides come into play, depending on operating conditions.

Flow ramp

An automated start-up sequence can be used when a well is first started to achieve minimum flow in a consistent, fast, and easy way. After the well is online, an operator can gradually ramp up the flow to the desired rate.

For example, the start-up sequence can bring a well to an initial flowing condition of 2 MMscfd of natural gas. An operator may want to reach 10 MMscfd over an 8-hr period. After an operator enters a desired end flow rate and time duration, the valve set point will automatically increase by an increment of 1 MMscfd/hr ((10–2 MMscfd)/8 hr) until 10 MMscfd is reached. At any time, a set point entered to reduce flow causes prompt reaction and is not subject to a ramping function.

Liquid loading

Whenever slug flow is present, liquid loading and subsequent unloading of the well must be addressed. As the well produces water, gas flow through the sales line decreases. The system's primary flow control programming responds to this change and opens the choke to compensate.

As the well unloads (water decreases), the gas flow increases quickly. The primary flow control programming will compensate and begin to close the choke; the reaction time, however, tends to be too slow. It is best to return production to an optimal level quickly and avoid tripping the well offline as a result of a high sales line pressure.

To accomplish this, the DP of the orifice run is monitored. The DP override can be tuned for faster response; therefore, it can return the well to normal flow control rapidly.

Manuscripts welcomeOil & Gas Journal welcomes for publication consideration manuscripts about exploration and development, drilling, production, pipelines, LNG, and processing (refining, petrochemicals, and gas processing). These may be highly technical in nature and appeal or they may be more analytical by way of examining oil and natural gas supply, demand, and markets. OGJ accepts exclusive articles as well as manuscripts adapted from oral and poster presentations. An Author Guide is available at www.ogj.com, click "Submit an article." Or, contact the Chief Technology Editor ([email protected]; 713/963-6230; or, fax 713/963-6282), Oil & Gas Journal, 1455 West Loop South, Suite 400, Houston TX 77027 USA. |

Another issue associated with producing water is ensuring that the well flow rate exceeds critical velocity. Critical velocity, determined by Turner and Coleman equations,1 2 implies the minimum rate of flow required from the well to lift liquids. Flow at less than critical velocity enables water to collect in the well, eventually curtailing production. In this case, a flow rate value can be entered manually or automatically calculated by the ROC unit using tubing ID, as well as real-time tubing and flowline pressure values.

The programming instructions within the ROC will select between the greater of the primary flow control and the critical velocity set points. In this way, flow will be maintained at the operator-specified set point until the critical velocity is reached. The control system then works to maintain the flow at sufficient rate to continue extracting liquids.

Transient flow conditions

Wells in the Haynesville shale play tend to reach vertical depths of up to 13,000 ft. Bottomhole pressures reach 10,000 psig with temperatures around 325° F. The maximum-allowed temperature of a typical sales pipeline is 140° F. A gas engine-driven cooler (Fig. 4) reduces the surface temperature of the product.

To prevent the well from tripping offline because of a wave of high temperature production, a high-temperature override PID loop responds rapidly to reduce the set point. Reducing the flow through the heat exchanger helps to maintain the average temperature at an acceptable level.

Other issues may exist away from the wellsite. Downstream gas-treating plants sometimes experience problems that cause the pipeline to back up. A PID loop will reduce flow and prevent high-pressure surges from tripping the well. PID loops in both cases can be tuned as necessary to adjust the flow to an acceptable rate. The reaction time is much less than that possible with the primary flow control-loop configuration.

Fig. 5 shows a response to high pressure. In this example, the well was flowing at about 10 MMscfd when a pressure spike to around 1,250 psig caused a sudden flow reduction. The flow eventually resettled around the primary flow set point with a new pressure control point determined by the operator.

The following four factors affect the preferred well flow rate:

1. High DP detected on the sales meter.

2. Water production, which may require that the primary flow rate set point be set to reflect critical velocity.

3. High temperature to the separator, which requires that the temperature be reduced to remain within the allowable temperature range of the sales pipeline.

4. High pressure to the separator, which requires that the flow rate be reduced to avoid high pressure shutdowns.

The programmed instructions of the ROC select the lower rate of these competing approaches to control the automated choke, ensuring that the well is maintained under control without violating any of the other conditions.

To assist safe operation, switches on site and a remote scada command can initiate an emergency shutdown (ESD) mode, overriding all other programmed instructions, and attempt immediate closure of the choke.

Economic benefits

The shale boom has greatly intensified the need to hire personnel in the oil patch. Work is sometimes delayed until skilled personnel can be hired or contracted or until other employees can be trained. In addition, local infrastructures are stressed by the influx of vehicles and people into the producing areas.

Consequential traffic problems have become a major incentive to reduce driving time. In this case, the control system both reduces time spent on the road and frees trained personnel from hours of rote effort, enabling them to tend to other wells.

Benefits of the control system include the following:

• Eliminates driving to restart a well that otherwise would have tripped offline because of high temperature or high pressure short term conditions.

• Enables personnel to get a well online in a faster and safer manner.

• Eliminates extensive time at a wellsite to perform actions to achieve an optimal flow rate.

Avoiding deferred production is another benefit. Because gas production flows to a pipeline, downstream problems of any type require reducing flow or shutting down the well. This automated system makes it possible to remotely modify set points and quickly return wells to operation.

References

1. Coleman, S.B., Clay, H.B., McCurdy, D.G., and Norris, H.L. III, "A New Look at Predicting Gas-Well Load Up," Journal of Petroleum Technology, Vol. 43, No. 3 (March 1991), pp. 329-333.

2. Turner, R.G., Hubbard, M.G., and Dukler, A.E., "Analysis and Prediction of Minimum Flow Rate for the Continuous Removal of Liquids from Gas Wells," Journal of Petroleum Technology, Vol. 21, No. 11 (November 1969), pp. 1475-1482.

The authors

Bob Sherven ([email protected]) is a control and automation engineer with Shell International Exploration & Production Inc. He has more than 25 years of industry experience with extensive exposure to instrumentation and control systems. Sherven has been acting as a control and automation technical authority supporting onshore gas assets in the US. He has a BS in chemical engineering from the University of California, Davis and is a registered professional engineer in California.

David Mudry ([email protected]) is an applications specialist for Vinson Process Controls in Dallas and has more than 20 years of product development experience. He is the architect and developer of Production Manager, an application designed for the Emerson ROC and FloBoss product lines specifically to facilitate wellhead optimization and product measurement. Mudry has an AAS in electronics technology from Odessa College (Odessa, Tex.).

Al Majek ([email protected]) is the Oil & Gas Production Area Technical Manager with the Emerson Remote Automation Solutions business unit. He has more than 30 years of experience in design, manufacture, and deployment of automation in the oil and gas industry. Majek has a BS in electrical engineering from Rice University. He is a Six Sigma Green Belt, certified project management professional, and a registered professional engineer in Texas.