HEAVY OIL REFINING—1: Understanding fines in coking more important now

Scott Sayles Sim Romero

KBC Advanced Technologies Inc.

Houston

Growth in the need to upgrade heavy crude oils, such as Athabasca bitumen and others, into synthetic crude oils as well as the need to process heavier conventional crudes is increasing the use of coking. Fines, or solids, in delayed-coker feedstocks reduce the ability of the coker to utilize capacity fully.

This first of two articles on the presence and effects of fines in delayed-coker feedstocks discusses the nature and sources of fines that enter a coking operation. The second, concluding article (OGJ, Feb. 4, 2013) will discuss the impact of fines and the mitigation steps that can improve reliability and profitability of the operation.

Fines enter delayed-coker feed from several different sources. Both inorganic and organic fines degrade delayed-coker reliability and overall refinery economics. In some cases, sudden changes in the refinery or a major upset in the refinery's desalter can bring down the delayed coker within hours.

In most cases, problems with solids fed to the coker are not as dramatic but still major.

Fines: types, sources

Fines can be classified as organic and inorganic, but there is considerable interaction between these categories.

• Organic solids are coke particles or coke fines and asphaltenes. Organic solids are at times a true solid (coke fines, corrosion products) and are also precipitated asphaltenes both of which form a third solid phase.

• Inorganic fines can be from oil sands bitumen, fluid catalytic cracking catalyst, ebullated-bed heavy oil hydrocracker catalyst, or corrosion from upstream equipment.

Inorganic or organic salts that can form from amine and chloride components can also be thought of as solids and can degrade operations of the delayed coker. This discussion does not address salt formation in the fractionator and downstream, as the breadth of that topic warrants separate treatment.

Organic fines

Organic fines are primarily hydrocarbons but typically have some inorganic constituents, such as metals, sulfur, oxygen, and nitrogen. Coke fines are the single largest type in a delayed coker. They can be a problem both in primary process operations and in ancillary operations such as coke cutting and coke handling.

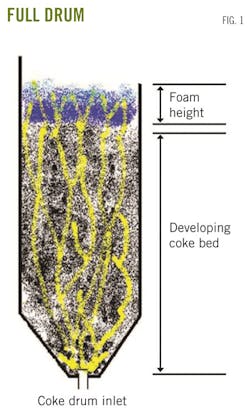

When the coke drums are being filled, coke fines can be entrained in the drum overhead into the fractionator as a result of high vapor velocities and high foam fronts. The fines are relatively consistent in shape and size. The very small fines, smaller than 50µ, are solid rectangular shapes with a specific gravity of about 1.7. A large quantity of larger particles can also exit with the vapor due to high velocities, full drums, and large foam fronts.

These larger particles can be as large as 0.25 in. or 50 mm. At some locations, these very large fines can actually be heard escaping the top of the drum. These large particles are less dense and can be spherical or resemble small shot-coke particles. These larger particles can be recovered in the fractionation bottoms' circulation system.

Sometimes sediment forms as a result of phase incompatibility among cracked products. The sediment can be asphaltene precipitation, wax formation, or other molecules that form solids as composition changes. Sedimentation can be reversible (waxes) or nonreversible (asphaltene precipitation). Much has been written about sedimentation, but it remains poorly understood. Sedimentation can manifest itself as a solid or as a sticky pitch or gum.

Historically, the delayed-coker feed asphaltene content, in conjunction with the Conradson Carbon content, is used to predict the propensity for sedimentation. Canadian feeds have relatively high asphaltenes content compared with typical crudes. Other feed types such as a deasphalted feed might have much lower asphaltenes content, while ebullated-bed vacuum residua would have more.

Asphaltenes are particles in the submicron range and can agglomerate to form micron-sized particles. These are often neglected in the discussion of fines and their impact on operations.

The vapors leaving the coke drum also entrain very small pitch particles in the form of an aerosol spray or mist. Again, the amount of unconverted heavy oils or pitch carried out of the drum is a strong function of the drum's vapor velocities, the level in the drum, and the amount of foam, or unconverted coke, at the top of the drum.

Fig. 1 illustrates a full drum with solids and pitch carryover.

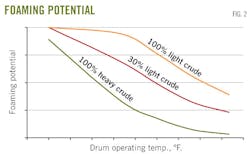

The height of the foam front in the online coke drum can be determined by taking several factors into account. The foaming calculations roughly estimate the foaming potential of different crude blends and how these blends interact under different coke drum operations, such as temperature, recycle, pressure, cycle time, and drum utilization or coke level in the drum.

Fig. 2 shows the general relationship of how two dissimilar crudes will interact as the coke drum temperature increases. The detailed impacts on foam height will depend on the qualities and ratios of the specific crudes in combination with coker operating conditions.

Inorganic fines

Inorganic fines are FCC catalyst, ebullated-bed catalyst fines, corrosion deposits, bitumen sand, and other <100µ solids entering the coker via the feed.

FCC slurry contains catalyst fines typically in the 20-60µ range. Catalyst fines have a very high surface area and relatively low density and are not removed by the bottoms' filtration circuit. The concentration can vary widely; most are <0.1 wt %.

Many techniques measure FCC catalyst slurry fines. The particle size and distribution are not routinely tested, but this can be done by the licensor upon request. The quantity of fines should be measured daily and is a monitoring point for the coker operation.

Ebullated-bed fines come from the vacuum tower bottoms of an ebullated-bed heavy oil hydrocracker and are in the 100µ range. This catalyst has a higher density and lower surface area than FCC catalyst. Due to their larger size and higher density, some of these fines would be removed by the bottoms' filtration circuit. Concentration is low, typically <0.02 wt %.

Corrosion products are generally iron sulfides or iron oxides as well as other typical scale materials. Physical properties and size are highly variable and unpredictable. Measurement is equally difficult, as often the corrosion products will enter the unit in a slug triggered by an upstream event (for example, returning a tank to service after cleaning). The bottoms filtration will remove some corrosion products, but not all. Some corrosion products such as iron oxide can foul the heater tube rapidly.

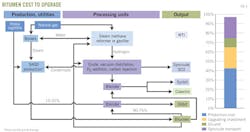

Upgrading oil sands bitumen increases the product quality from the extracted bitumen to synthetic crude oil. Fig. 3 shows that the value of the product increases in relationship to the quality, but this requires higher production costs and operational complexity.

Bitumen is upgraded with a primary bottom-of-the-barrel process such as an ebullated-bed hydrocracker or delayed coker. Bitumen is separated from the sand and most of the sand is removed and returned to the excavation site. Some of the sand remains, however, and is transported into the primary upgrader.

Bitumen sand is a high surface-area particle surrounded by bitumen. The particles are 1-10µ and not filterable. The silt-like quality of these particles allows them to migrate throughout the piping systems as a suspension with the oil.

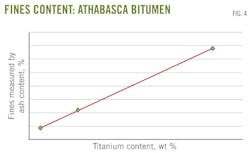

Analyzing the oil for titanium can detect these particles. The titanium concentration is low, typically 1-20 ppm (wt), but is a good marker for inorganics originating from bitumen silt. The change in titanium concentration is one of the significant differences and is a good marker for silt originating from Athabasca bitumen. The titanium content is proportional to the fines content of the bitumen (Fig. 4).

Other sources of inorganic solids are slops originating from the coke drum's overhead line quench and from gray water used to cool or quench coke in the drum. The solids in the water are typically coke fines, but the water can also contain a variety of inorganic solids as well.

Solids, both organic and inorganic, introduced in the cooling and quench of the coker rarely enter primary processing operations and are confined to the coke cutting and quench water system and the coke-handling system. Slops injected into the coke drum overhead line as a line quench, however, will enter the process directly and will have immediate consequences.

The authors

Scott Sayles ([email protected]) is a principal consultant for KBC Advanced Technologies Inc., Houston, with more than 30 years of refinery and petrochemical experience, ranging from refinery plant manager to research engineer.His technical areas of expertise include operation and design, ebullated-bed residua hydrocracking, hydrotreating, FCCU, and practical understanding of most processes. Sayles is a member of the American Fuel and Petrochemical Manufacturers. He holds a BSChE from Michigan Technological University, Houghton, Mich., and an MSChE from Lamar University, Beaumont, Tex.

Sim Romero ([email protected]) is a principal consultant for KBC Advanced Technologies Inc. with more than 30 years as a chemical engineer. He spent 11 years with ConocoPhillips in delayed coking, then 7 years with BP Oil in heavy oils and delayed coking. He moved to ARCO then back to the Conoco/Bechtel Alliance in delayed coking, with a short stay with ExxonMobil, and then spent 7 years with Valero as director of heavy oils and delayed coking, before joining KBC. Romero is a member of the American Fuel and Petrochemical Manufacturers and sits on the technical steering committee for Coking.com. He holds a BS in chemical engineering from the University of New Mexico, Albuquerque.