Study details HVDC stray-current effects on pipelines

Based on presentation to NACE Corrosion 2010 conference, San Antonio, Mar. 14-18, 2010.

Currents from high-voltage direct current faults can damage underground-underwater pipelines. This type of DC current is picked up on underground pipelines and can travel in the pipe wall for a considerable distance before discharging.

Since HVDC faults are a steady state flow of current lasting from a few minutes to several days, severe damage can occur to a pipeline at the site where the current discharges.

Pipeline operators need to be vigilant in areas affected by HVDC stray currents. Stray-current mitigation systems should be installed and maintained well to ensure the pipelines are not compromised by corrosion due to stray current discharge.

Background

The first reported high voltage direct current transmission system (Gotland 1) with mercury arc valve converters entered service in 1954. Conversion methods have improved since, with thyristor control used principally today. Operating voltages have also increased, with as much as ±500,000 v to ground, allowing for higher wattage transmission and increasing the power available to consumers.

The first North American HVDC transmission system was the British Colombia-to-Vancouver Island monopolar system (1968) transmitting 312 Mw at 260 kv through an undersea cable. The Pacific Intertie (1970), a bipolar system transmitting 3,100 Mw, and the Nelson River bipolar system (1971), transmitting 1,620 Mw at ±450 kv, followed.

The Quebec-New England Intertie entered service in 1991 as a 2,000-Mw system operating at ±450 kv. Power capability has increased since to about 2,500 Mw. This article details the effects of this HVDC system on crude oil and natural gas transmission pipelines linking Portland, Me., and Montreal.

The most recent HVDC system commissioned in North America is the Cross Sound Cable Interconnector (2002), a monopolar system operating at 330 Mw. It measures 40 km in length and uses a light buried submarine cable system connecting the electric transmission grids of New England and Long Island, NY.

Monopolar HVDC systems use the earth (generally seawater) for return current flow. The power is generated as alternating current at the source then converted to DC current flowing via a cable to the load where it is converted back to alternating current by the thyristors. Return current flows through the earth from the load terminal to the source converter station.

Bipolar HVDC systems use two conductors, one from the source to the load and a return conductor from the load to the source. Bipolar systems also have a ground electrode to allow imbalance current to flow from the source to the load or from the load to the source through the ground. These imbalance currents usually measure less than 100 amp and may flow continuously for hours.

During system upset or planned maintenance, power may flow through either Line 1 or Line 2 with the return current flowing through the earth back to the source. Such events can result in thousands of amperes of current flowing through the earth circuit, causing direct current interference with underground-underwater pipelines and utilities.

Case history

Extensive testing in 1990 at current levels of 700 amp preceded commissioning of the Quebec-New England Intertie in 1991. DC fault current from the testing affected a number of utilities and pipelines, including stray direct-current saturating distribution transformers of New England's rural electrical system. The initial concept for the HVDC transmission system included a bipolar system running from the generators at Radisson, Que., on James Bay to Sandy Pond northeast of Boston, with intermediate stations at Littleton, NH (now decommissioned), Duncan, Que., and Nicolet, Que.

Following initial testing, New England Power ran an aerial return conductor (insulated from the towers) on the HVDC towers from Sandy Pond to Duncan to reduce the fault current flow in the earth circuit in New England, yielding a change in the HVDC stray-current pattern on the pipelines affected by the HVDC fault currents.

HVDC fault current affects underground-underwater pipelines. The pipelines pick up the current, which travels in the wall of the pipeline for a considerable distance before discharging. Since HVDC faults are a steady state flow of current, lasting from a few minutes to several days, severe damage can occur to a pipeline at the current discharge location.

Installed stray-current mitigation systems safely drained DC fault currents from operating cross-country pipelines. The drainage scheme worked for a number of years, but changes occurred over time. New pipelines were run, existing pipelines modified, and telephone utilities changed from lead-sheathed cables to plastic or fiber-optics.

Pipelines and utilities requested a new series of fault tests. The first occurred Nov. 4, 2006. In conjunction with Quebec Hydro and New England Power, the pipelines established a test pattern that would be easily recognized in the event of large telluric activity during the test.

At the bottom of each hour, the test would discharge 1,200 amp into the ground electrode at Duncan (the south electrode) for 4 min. Current discharge would stop for 2 min at the end of the 4-min interval, before discharging 1,200 amp from the ground electrode at Radisson on James Bay for 2 min, the current being picked up on the ground electrode at Duncan.

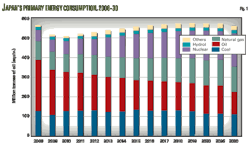

This test pattern was repeated hourly on the half hour from 07:30 hr to 19:30 hr (Fig. 1). Current flow and pipe-to-soil potentials were recorded for about 15 min at test stations in Maine and Quebec. Results showed pickup and discharge areas for the HVDC stray currents having changed in both magnitude and location.

Immediately after commissioning in 1991, the current-discharge area lay principally in Quebec from the Vermont border north to St. Cesaire. The Nov. 4, 2006, test showed the current-discharge having shifted to principally south of the Canadian border in northern Vermont, requiring a second test to define the actual area of current pickup and discharge. The onset of winter forced postponing this until June 2007.

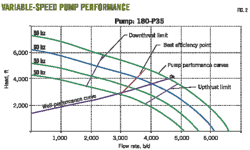

The second test started at 09:30 hr, June 18, 2007. Both tests used a digital recorder installed at Scenic Road, Que., to record pipe-to-soil potential of the crude oil pipeline for each second. Fig. 2 shows the recorded pipe-to-soil potentials from 09:15 hr to 16:59 hr, June 28, 2007. Fig. 3 shows test faults occurring as scheduled hourly on the half hour, with a potential swing of about 500 Mv.

Obtaining as much information as possible during the June 2007 test required refurbishing test stations and, where necessary, equipping them with IR drop leads to measure current flow. The 18-in. and 24-in. OD crude oil pipelines were coated with coal tar enamel and Kraft Rapp, respectively, with an abandoned bare 2-in. line in the middle of the right-of-way.

Getting an accurate assessment of the effect of HVDC stray currents required recording the current flow and pipe-to-soil potential of both the 18-in. and 24-in. lines. Voltage across a length of the pipeline recorded current flow and the pipe-to-soil potential was recorded each second for about 20 min during the fault test.

Going south from the Canadian border through Vermont, the pipelines picked up HVDC stray currents. Their magnitude increased through the Missisquoi River Valley, then diminished farther south.

Fig. 3 shows the effect of the HVDC fault current on the pipe-to-soil potential of the 24-in. line at the first road south of the Canadian border. A fault current of 1,200 amp caused a pipe-to-soil potential change of 300 mv. Fig. 4, taken a mile south at the Missisquoi River crossing, shows a potential change due to HVDC fault current at 1,200 amp of 700 mv. At both locations, when the south electrode was an anode (current discharge into the soil), the pipelines picked up current. When Radisson was an anode and Duncan a cathode current instead discharged at these locations.

Fig. 5 shows the current flow through the 24-in. pipeline at this location as less than north and south of Mile Post 159.

The pipe-to-soil potential shift at Collins Mill Road on the north side of Black Mountain increased to 900 mv but reversed in Fig. 6, indicating current discharge when Duncan is an anode. This pattern occurs through Black Mountain and reverses back to a normal condition (pickup) on the south side of Black Mountain at Tay Road, Irrasberg, Vt.

A discharge area should not exist in the middle of a pickup section. Further research found a narrow, low-resistance graphite ore body running northeast-southwest and crossing the pipeline right-of-way on the north slope of Black Mountain, suggesting the HVDC current is discharging from the pipeline into the ground and traveling along the graphite ore body to the Duncan ground electrode.

Fig. 7 shows the pipe-to-soil potential at Tay Road. The pipe-to-soil potential here demonstrated pickup, showing the pipeline to now be clear of current discharge. Fig. 8 is the companion current flow recording on the pipeline. Telluric current, not the HVDC current, caused the rapid fluctuations.

Fig. 9 shows the pipe-to-soil potential at Route 16 in Barton several miles farther south as having diminished current pickup. Fig. 10 is a recording of the current flow through the pipeline at this site. Current flow had diminished as compared to recordings farther north.

On Mar. 23, 2007, the south electrode was a cathode and received 1,058 amp of current for 29 min, meaning the pipelines running from the Canadian border to south of Barton, Vt., were discharging current. On Apr. 13, 2007, a fault occurred on the HVDC system and the Duncan electrode became an anode discharging 2,228 amp for 17 min. Previously recorded system faults had lasted more than 24 hr.

These long duration current flows can damage coated pipeline by concentrating the current discharge at holidays in the coating.

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com