Continuous well-flow estimates improve production allocation

Evidence from several Shell operating units confirms that daily allocation based on continuous well flow estimates can be more accurate than the more traditional approach based on well testing.

The key point is that continuous allocation on a well-by-well basis, using a software application such as Shell's FieldWare Production Universe (FW PU) assigns the right production to the right wells, unlike the traditional monthly, batch approach that erroneously allocates the difference between fiscal and well test measurement across all wells.

Reference 1 reports similar findings or increased accuracy of daily allocation when compared with monthly.

Several Shell operating units have adopted the continuous-allocation approach and automatic daily production key-performance-indicator reporting based on real-time well flow estimates.

Allocation

The oil industry reconciles fiscally measured hydrocarbon production with estimated production from associated wells. This process, known as allocation, is important for several reasons including accounting for field production to owners and governments, field surveillance, and volumetric input to reservoir simulators.

Traditionally companies perform allocation monthly, reconciling the less accurate sum of the well tests adjusted by well uptimes with the more accurate fiscal measurements. This process has several inherent inaccuracies including less-than-perfect well tests, lack of precisely knowing when wells were off production, unknown well flow changes, and the methods for allocating the difference between fiscal and well test measurements.

Ineffective allocation can lead to financial consequences because of inaccuracies in volumes allocated between multiple owners and various tax regimes.

Inaccuracies can also feed through to reservoir simulators that assist in decision making such as where to drill the next well. These inaccuracies often compound with time, as monthly allocation occurs during the field's life cycle.

Hydrocarbon accounting

Hydrocarbon accounting systems prepare and store reconciled production and injection data on a well at the conduit, reservoir, block, and zone level with the following objectives to:

• Account for fluid volumes transported in production systems from the source (reservoir) to the point of sale.

• Differentiate the ownership of hydrocarbon fluids.

• Assist production planners regarding hydrocarbon offtake schedules.

• Inform operations and petroleum engineering staff regarding reservoir, well, and production facility behavior.

• Maximize the validity and integrity of hydrocarbon accounting data for report, audit, and review purposes.

Hydrocarbon accounting culminates in a monthly report of producing wells. The MRPW is the official production record used for fiscal, audit, and reporting purposes.

MRPW data provide volumetric input to reservoir simulators that in turn help make decisions regarding future field developments. The data also provide a way to track and record reservoir reserves.

Shell calls the concept of adjusting individual conduit volumes such that their sum equals the related fiscal measurements as reconciliation. The term allocation is the calculation whereby the official conduit volumes (produced or injected) are assigned to the related reservoir units.

A flaw in the traditional hydrocarbon accounting process is the assumption that the flow during a well test (about 1% of the time) equals the flow of when the well is not on test (about 99% of the time). This assumption is questionable because:

• Well rates can vary unpredictably between well tests due to natural decline, especially during later stages of the life cycle.

• Well stream composition can suddenly change, for example from increasing water cut or increasing GOR.

• Production rates of artificially lifted wells can vary between well tests due to the effects of variables such as backpressure (gas lift) and pump speed and efficiency (electric submersible pumps, progressing cavity pumps, beam pumps, and hydraulic lift).

• Production from wells in enhanced oil recovery can change unpredictably due to changes in gas, water, steam, or polymer flows in the reservoir.

• Variable periodic production in wells that are on intermittent gas lift and gas wells subject to periodic liquid loading;

• Produced wax, ashphaltines, or scale that foul production lines, which need to be cleaned often.

All of the above unpredictable instabilities are aggravated by flaws in the basic well test process such as:2

• Wrong well put on test.

• Wrong instrumentation used, such as improperly sized or damaged orifice plate.

• Inaccuracies in well test instrumentation due to improper calibration or lack of maintenance.

• Improperly ranged well test instrumentation such as testing a well producing at low rates with instrumentation sized for wells producing at high rates.

• Testing wells at flow and pressure conditions that differ from normal flow conditions, especially for wells with high backpressure such as step outs and subsea wells with long flowlines.

• Commingled subsea wells without a dedicated test line, forcing testing by difference at test conditions that may vary from normal flowing conditions.

Operators can mitigate the effects of these flaws with techniques that continuously estimate well flow rates.

They can also use continuous estimation of well flow rates to produce automatic daily reports of key performance indicators such as daily well oil, gas, and water production and deferment rates.

Shell's estimation technique

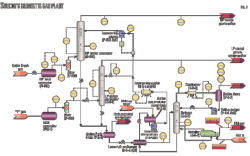

Shell developed the FieldWare Production Universe data-driven modeling application for continuously estimating well production. References 3-7 describe the development background and Shell's early operational experiences with the application.

Data-driven models provide a virtual continuous three-phase meter for all wells.

The data-driven approach takes full advantage of the well test and available real-time production metering in conventional production operations, particularly with regard to changing well conditions and instrumentation uncertainty.

The technique requires an abbreviated multirate well test along with historic well-test results as input for the modeling process that generates data-driven well models. These models relate the three-phase flow from the well on test with signals from the wellhead instrumentation, such as tubinghead pressures and temperatures, lift-gas injection rates, and production choke openings.

The software application automatically retrieves well test and instrumentation signals from associated production data systems such as supervisory control and data acquisition systems, distributed control systems, or historian systems.

After completing the construction of a model for each well, the software application uses the model to automatically compute oil, gas, and water rates for each well. The application also retrieves bulk, fiscal station oil, gas, and water signals from production data systems and then performs a continuous material balance in which the well flow's estimates provide the flow in and the bulk measurement gives the flow out.

The ratio of total well-flow estimate to total measured bulk/fiscal flow equals the allocation factor.

The software application has an intuitive graphical user interface for operator data load/display and well-model configuration and validation. The process automatically uploads subsequent well tests into the application for model validation or updating. Algorithms within the application automatically indicate when a model requires updating (retesting).

The use of data-driven models for well production surveillance provides a number of advantages, such as simplicity of the approach and how it incorporates and extends the conventional well testing process. The process requires no numerical assumptions about the underlying physics of the well.

In an operational environment with limited engineering resources, the process does not require frequent wellhead instrumentation calibration. The application only requires repeatable well measurements; within limits. Absolute measurement accuracy is not critical.

To ensure robustness, the application creates several independent data driven models for each well using different inputs such as multiple fallback models based on some or all of the following parameters: wellhead pressure, wellhead temperature, manifold pressure, bottomhole pressure. This allows well estimates to continue should an individual instrument fail. This also allows the model to identify and report malfunctioning instrumentation.

The net effect is that FW PU real-time well flow estimates, comparison with bulk measurements, fallback models, and easy-to-use graphical user interface provide:

• Automatic daily production and deferment totals for individual and collective wells.

• Real-time crosscheck on the quality of the estimates indicating when wells need retesting and pinpointing instrumentation problems;

• Estimated well flows (when the wells are not on test) by streaming real-time well data to the models. The process also automatically compares the sum of the estimated well production with real-time, single-phase flows as physically measured by export or bulk meters.

• Daily allocation factors.

• Applicable to all well types such as naturally flowing, artificially lifted, unstable, onshore, offshore, deep water, shallow water.

• Applicable to all well sizes.

• Fast, easy to sustain and cost effective implementations.

Four case studies compare continuous allocation using Shell's software and discontinuous allocation using the traditional well test approach.

Offshore platform

Fig. 1 compares continuous well-flow estimation vs. flow derived from discontinuous well tests for an offshore platform producing 50,000 boe/d from 33 platform wells and 2 subsea tiebacks. All wells are on gas lift and have water cuts ranging between 10% and 95% with an overall GOR of 78 scf/scf.

In the facility, operators used to measure three-phase flow by periodically routing the wells to a test separator, with well production interpolated from test to test.

They also tried physical models in combination with real-time wellhead pressure and temperature to estimate three-phase flow from the wells, but they found this method difficult to sustain in an operational environment.

Consequently, the operators tried the FW PU application for estimating three-phase flow continuously for each well.

They used these data for daily well allocation in which the sum of the well estimates divided by the overall platform oil production rate derived a daily allocation factor.

They also calculated allocation factors daily from well tests, adjusted by well uptime and then summed across all wells and divided by overall platform oil production rate.

Fig. 1 compares the two methods. As can be seen, the FW PU method provides a fairly stable allocation factor in the range of 1.0, whereas the well-test method has a relatively unstable factor that averages about 0.88 on the low side.

The field operator subsequently has adopted continuous allocation FW PU well-flow estimates.

FPSO

Another illustration on the use of the application is from a spread-moored floating production, storage, and offloading (FPSO) vessel with 2 million bbl of oil storage, off West Africa. The facility is in a 3,200-3,700 ft water depth and handles about 200,000 bo/d of production and about 300,000 b/d of water injection.

The FPSO ties in 13 subsea production wells and 13 subsea water injectors.

The well with the highest production capacity can produce 50,000 bo/d and the well with the highest injection capacity can inject 70,000 b/d.

The wells are on five subsea manifolds each with two flowlines to the FPSO. The production risers, connecting the flowlines to the FPSO, include an option for gas lift if required.

The operation initially used the traditional hydrocarbon accounting and allocation approach. In this case, the operators obtained well-interrupt times from real-time pressure readings at the subsea and FPSO DCS control systems and hence these times were accurate within reason.

Fig. 2 compares the traditional allocation approach with the continuous flow estimation of oil, gas, and water. As can be seen in this case, the old method gave allocation factors which erred 4% on the high side, whereas the new method averaged 0.05% on the low side.

The field operator subsequently adopted continuous allocation.

Long subsea tieback5

A third example is a subsea cluster consisting of eight wells tied back to a remote platform via a 60-km flowline with no separate test line due to the length of the tieback.

The operation measured total production on the remote receiving platform. Initially each well had three downhole pressure (BHP) gauges and a downhole venturi meter. The combined measurements of pressure drop over the venturi and density in the wellbore allowed for the estimation of production rates. In addition to these downhole flowmeters, the subsea flowlines from each wellhead to the drill center also had venturis installed.

Although seemingly robust, the operation overestimated the reliability of the subsea and downhole metering equipment. One downhole flowmeter failed at start-up. Initially, production estimates from the other wells proved sufficiently accurate for allocating by difference the production of the well with the failed equipment.

During the second and third years of production, however, signals from the other downhole flowmeters stopped or became unreliable. The subsea venturis also proved unreliable due to blocked impulse lines, inadequate density measurement, and faulty associated instrumentation (tubinghead pressure and temperature).

The combination of no data with inaccurate data affected the understanding of the production from the field and impeded allocating and optimizing production.

Consequently the operator deployed the FW PU to estimate continually the highly variable production behavior of each well's oil, gas, and water flow.

Although the application had previous successes in subsea fields, this subsea cluster required a new approach. The 60-km long flowline resulted in a time delay between the changes in bulk meter and well variations, making it difficult to effectively test wells.

As such, the challenge was to use the available continuous real time and historical well measurement and commingled production data optimally, with an end target of providing an operationally sustainable real-time application for continuously estimating well-by-well production.

This involved the building of initial data-driven models using total commingled production data during the preceding time period and then calculating production rates from the downhole flowmeters during the periods that this data was available.

Validation and calibration of the downhole flowmeter data used testing by difference data for allocating some of the total production to individual wells. The resulting FW PU models provided real-time well production estimates, which tracked the steady-state production metering values (Fig. 3).

After a period of observation, analysis of the estimates against operations expectations, actual production events and total production values, found a fairly good fit.

This led to a recommendation to use FW PU as a basis for production reporting and allocation for the field.

Multizonal smart wells.

The last example is from multizonal smart wells. In this case, the application uses the mechanical configuration, annulus and tubing downhole pressures, and the associated inflow control valve openings, for generating data-driven models for individual zones in the wells.

The zonal models then provide production estimates for the individual zones in real time, working from the real-time downhole pressure gauge readings and inflow-control-valve settings.

These zonal flow estimates are the basis for the continuous allocation. The software continuously compares the sum of the allocation flows with the total well production that may be measured with a multiphase flowmeter.

If a MFM is not installed, the operation assumes that total well flow is the sum of the individual zonal flows and then the process continuously compares this sum along with FW PU-derived flows for all other wells in a given field with the measured total flows for that field.

The building of the FW PU data-driven models for the zones requires a series of specifically designed tests in which test flows of individual zones and combinations of zones of the smart well flow to a surface test separator or MFM. The test includes varying the zonal ICV settings and recording the downhole and surface pressures and temperatures.

In general, well tests of zones flowing one zone at a time are inadequate because the pressure regimes will be different when all zones flow together. The zones also interact with one another. It is therefore desirable to have the zones flow together for at least part of the test.

From the tests, the application can derive models for estimating individual zonal production for oil, gas, and water based on, for example, ICV position and differential pressure across the ICVs.

On completion of the well testing and modeling, the models are put online. Based on real-time data on ICV positions as well as downhole pressures, the zonal models estimate production from each zone in real time and report and allocate produced volumes daily.

Fig. 4 illustrates the individual zonal liquid flow continuously estimated by the application. The figure shows well flow estimate as the numeric sum of the individual zonal estimate and the total well flow periodically measured by the test separator. As can be seen, the FW PU estimated total of the zonal flows matches well with the test separator measured flow.

References

1. Lerma, P.G., et al., "Allocation Process Modeling for Deepwater production," Paper No. SPE 101318, IPEC, Abu Dhabi, Nov. 5-8, 2006.

2. Cramer R., et al., "Well Test Optimization and Automation," Paper No. SPE 99971, Intelligent Energy Conference, Amsterdam, Apr. 11-13, 2006.

3. Poulisse, H., et al., "Continuous Well Production Flow Monitoring and Surveillance," Paper SPE 99963, Intelligent Energy Conference, Amsterdam, Apr. 11-13, 2006.

4. AlKhadhuri, S., et al., "Integration of People, Process and Technology for Right-Time Production Management and Optimization in Brunei Shell Petroleum," Paper No. SPE 99243 Intelligent Energy, Amsterdam, Apr. 11-13 2006.

5. Dolle, N., et al., "Combining testing-by-difference, geochemical fingerprinting and data-driven models: an integrated solution to production allocation in a long subsea tieback," Paper No. SPE 108957, Offshore Europe, Aberdeen, Sept. 4-7, 2007.

6. Gerrard, C., et al., "Implementing Real Time Production Optimisation in Shell Exploration & Production in Europe—Changing the way we work and run our business," Paper No. SPE 108515, Offshore Europe, Aberdeen, Sept. 4-7, 2007.

7. Goh, K.C., et al., "Production surveillance and optimization with data driven models," Paper No. IPTC-11647, IPTC Conference, Dubai, Dec. 4-6, 2007.

The authors

Nick Colbeck previously worked for Shell E&P in various operations around the world. While head of production programming and allocation for Shell's Nigerian deepwater asset, one of his responsibilities was working with the Fieldware Production Universe. He currently works as petroleum engineering team lead with Hess Corp. in Indonesia. Colbeck is a graduate of the University of Glasgow.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com