Industry CO2 EOR experience relevant for carbon capture and storage (CCS)

| This article contains highlights of SPE 126446, "Industry Experience with CO2-Enhanced Oil Recovery Technology," presented at the SPE International Conference on CO2 Capture, Storage, and Utilization, San Diego, Nov. 2-4, 2009. |

The petroleum industry's long history of successful carbon dioxide enhanced oil recovery (EOR) operations can make substantial contributions to improve and accelerate the deployment of carbon capture and storage projects.

For instance, industry has developed sophisticated technologies for oil and gas operations that can be applied to CO2 storage integrity and monitoring applications.

Since the first patent for CO2 EOR was granted in 1952, the oil and gas industry has spent many tens of billions of dollars developing and implementing CO2 EOR technologies.

The first large-scale, commercial CO2 EOR project began operation in 1972 at the SACROC field in West Texas, which continues in production today. Many more projects have started since then and by 2008 had reached a total of 112 projects (89% of total 126 globally) in the US and Canada.1

Underground geological storage of CO2 is a promising technology for reducing greenhouse gas (GHG) emissions. Technology developed by the oil and gas industry for natural gas processing and CO2 EOR can support the sound implementation of CCS.

The Intergovernmental Panel on Climate Change (IPCC) clearly considers EOR as a form of underground CO2 storage. In CO2 EOR, storage occurs as CO2 displaces hydrocarbons from reservoir pore spaces and the injected CO2 is trapped through capillary forces and other mechanisms.

The industry's processes and experiences relevant to CCS include separating (or capturing) CO2 from oil or gas production, pipeline transportation to EOR projects, and design and operation of surface and subsurface systems for injection of CO2.

Kinder Morgan has estimated that 655 million tons of CO2 have been injected in Permian Basin EOR projects in the past 37 years. This amount is equivalent to the total CO2 emissions of four to five 500 Mw capacity coal-fired power plants.

The 2008 OGJ EOR Survey reports that 15,373 wells (94% of all CO2 EOR wells) including 9,144 producers and 6,229 injectors are operating in 105 CO2 EOR projects in the US and 975 wells (6% of all CO2 EOR wells) are in operation in other countries.

Industry CCS activity

Oil and gas industry companies participate in research consortia and fund research at major universities to answer the technical and policy questions surrounding GHG management, including CCS.

The Carbon Dioxide Capture Projects (CCP & CCP2), Gulf Coast Carbon Center (GCCC), CO2 Remove, Carbon Mitigation Initiative, and the Global Climate and Energy Project (GCEP) are prominent examples of such consortia.

The American Petroleum Institute is continually developing recommended practices, standards, and other information to ensure the ongoing safe and environmentally sound operation of CO2 EOR operations. These same standards and practices, based on extensive industry experience should help government agencies or regulators prepare sound rules for CO2 injection facilities and wells.

Additionally, API and International Petroleum Industry Environmental Conservation Association (IPIECA) have developed guidance on accounting for CO2 emission reductions associated with CO2 storage projects.

Fig. 1 compares the volumes of CO2 injected by several oil and gas projects to the amount of CO2 sequestration needed for a large coal-fired power plant.

It is generally accepted that injected CO2 will react with the in situ formation water to create a weak carbonic acid solution, which is the basis for much of the concerns raised regarding CCS.

However, geochemists and others have found that the geochemical reactions that occur in geologic storage reservoirs can substantially affect the amount of carbonic acid formed. This is because CO2 molecules in reservoirs have difficulty hydrating and are easily buffered due to in situ formation water's salinity and mineral content compared to molecules mixed in fresh water in metal or glass lab containers or testing devices.

Cations from mineral salts and combinations of them present in reservoirs can limit decreases in the brine water's pH from CO2 injection through mineral buffering and sustain much less corrosive environments than some researchers have claimed.2

Actual pH values of fluids in contact with well cements and pipe may average between 4.5 and 5.5, which are considered weakly acidic conditions compared to the much more acidic conditions created in lab tests by some researchers and by unrealistically low calculated values by some software models that attempt to predict pH conditions.

Smyth et al.3 worked on a CO2 geochemical laboratory testing project at the Gulf Coast Carbon Center, Bureau of Economic Geology, Jackson School of Geosciences, The University of Texas at Austin (BEG/UT). They report that under simulated geochemical conditions, pH values can drop rapidly when CO2 is introduced and then rebound to higher values.

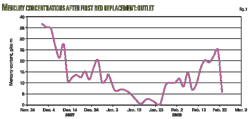

Lab-generated pH values help explain why higher than expected pH values in Fig. 2 were measured in a U-tube device under downhole conditions at the Frio CCS test project.4

The mineral buffering effect may typically occur in storage and EOR reservoirs and should be simulated in lab testing procedures for well material (cement, pipe, etc.) selection and in software modeling applications to predict corrosive conditions (pH vs. time) during all phases of the project.

In 2007, API completed a study to compile CO2 EOR injection well technologies representing the state of the art. A survey of operators, representing most US projects, was conducted to better document best practices and to review records of operational performance.

Survey results included many findings that had not been clearly presented before, particularly in the context of the concerns around CCS. For example, to cement wells, CO2 EOR operators have used Portland cement-based well cement systems almost without exception and significantly, without adverse loss of CO2 containment. These cost-effective, conventional cements were designed to have sealing and structural support properties suitable for the CO2 EOR application.

The weak in situ acidic conditions help explain why operators have successfully used Portland cement-based systems to seal and support wells in CO2 EOR projects. The extreme degradation of cement common in many lab test results is likely due to the absence of mineral buffering and not matching other reservoir conditions.

Zonal and integrity studies

During the last 9 years, representatives from government, academic, and industry organizations of the API Task Group on Annular Flow Prevention studied the causes and prevention of annular flow incidents and sustained casing pressure (SCP) in wells, which are recognized indicators of poor well cement integrity.

Two API recommended-practice publications (RP 65 Parts 1 and 2) were prepared and approved that describe preventive measures for any potential flow zone in any type of well including those in CO2 zones. Preventative measures include key well planning, drilling, mechanical barrier, and cementing practices designed to help ensure cement integrity and isolation of potential flow zones.

Achieving cement integrity and zonal isolation in the presence of a potential annular flow of CO2 can require not only the modification of the cement properties to facilitate control of migrating formation fluids and CO2 but also several other practices including:

• A stable wellbore: no fluid losses or gains prior to, during, and after the cementing process.

• Adequate annular circulating flow clearances to help prevent abnormal displacement pressures.

• Proper mud-hole conditioning prior to cementing to remove cuttings, gelled mud, and excessive filter-cake.

• Spacer designs that help remove mud and leave pipe-formation surfaces water-wet for better cement bonds.

• Casing centralization to allow better placement of cement all around the pipe.

• Proper tripping requirements to help prevent negative effects by excessive swab-surge pressures.

• Proper drilling techniques to help ensure hole quality and minimize washouts, spiraling, and ovality.

• Well monitoring to help ensure cementing pressures, pump rates, and densities meet designed values.

• Waiting on cement (before start of well operations) for a sufficient period to allow undisturbed cement curing.

• Use of mechanical barriers when appropriate to help overcome problematic conditions.

Operators can minimize the risk of CO2 migration by using multiple pressure barriers installed in wells in the form of multiple casing strings from the surface of the well to its total depth, mechanical pressure barrier devices (packers, etc.), and the cemented sections around each pipe, as explained in RP 65.

Note also that RP 65 effectively deals with preventing methane migration, which is much more difficult to prevent than CO2 migration. This is because methane is an inert gas with more buoyancy than chemical reactive CO2 molecules that can seal leak pathways by precipitating CaCO3 scale.

CO2 containment studies

• At US Environmental Protection Agency (EPA) and International Energy Agency meetings in March 2007, Koplos et al.5 presented a well integrity study of Underground Injection Control injection wells that included data from EPA studies of Class II (CO2 EOR) injection well mechanical integrity tests (MIT) and reported "No reported underground saltwater disposal well (USDW) impacts associated with wells with any known internal or external MIT failures in the 1983-92 period."

• The IEA GHG R&D Program's Monitoring Network reported on soil gas sampling measurements at the Rangely field CO2 EOR project and concluded that the total amount of CO2 leakage from the EOR zone was less than 0.01% over 15 years of CO2 EOR operation. The IEA report also stated that there is no evidence of CO2 leakage from the storage reservoir at other CCS projects including Weyburn, Frio, and Sleipner.

• Smyth et al.3 at BEG/UT is evaluating CO2 containment at the SACROC CO2 EOR project. Smyth et al.3 has reported that water sample testing from 68 wells and one spring indicate that no CO2 leakage from the EOR zone into the USDW zones in the field has occurred after 35 years of CO2 injection operations.

• Finally CCP has been studying the effects of CO2 on well integrity via a wellbore sampling and laboratory analysis program under way since 2006.

CCS development practices

The oil and gas industry has a great record in sound development for operational surface facilities and wells in environmentally and politically sensitive site locations. This usually involves the use of health, safety, and environmental and well integrity standard industry practices with oversight by local regulators and community representatives.

The oil and gas industry has developed a highly sophisticated suite of technologies for petroleum operations that can be applied to CO2 storage integrity monitoring applications. These intermittent and long-term monitoring methods include: wireline conveyed logging tools run in production, injection, and monitoring wells; seismic array data imaging; wellbore pressure monitoring by wellhead and downhole gauges; injection and production volumetric monitoring by flowmeters; subsurface to surface deformation measurements via tilt meters and satellite radar; gravity surveys, etc.

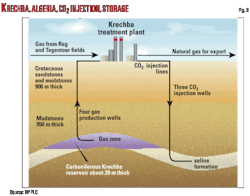

Carbon dioxide injection wells are part of Krechba, one of eight Algerian gas fields that are part of the In Salah gas project. Operators inject CO2 into a deep saline formation. Photo from BP PLC.

The applicability of these techniques is site specific, and selection requires an understanding of the site's subsurface characteristics, as well as the measurement capabilities of the various techniques in order to match the site's monitoring, verification, and accounting objectives.

Monitoring, whether direct (e.g., observation wells) or indirect (e.g., seismic), can only evaluate limited geographical areas-points at a point in time. Computer modeling serves as a proxy for visualization of what cannot be seen and for predicting CO2 plume movements in the future.

In Salah case history

Krechba is one of eight gas fields comprising the In Salah gas project in central Algeria that includes an industrial scale CO2 storage project that has been in operation since 2004.6

CO2 from several gas fields, which have a CO2 content of 5-10%, is removed from the production stream to meet the sales gas export specification of 0.3% CO2.

Rather than vent that separated CO2 to atmosphere (as was normal industry practice for such gas plants), BP and its joint venture partner Sonatrach invested an incremental $100 million in a project to compress, dehydrate, transport, and inject that CO2 into a deep saline formation downdip of the producing gas horizon.

The former StatoilHydro then joined the JV at production startup in August 2004. The investors derive no commercial benefit from the CO2 storage at In Salah, so it is being used as an experimental and demonstration project to learn about CO2 geological storage in deep saline formations.

The injection formation (Fig. 3) is a 20-m thick Carboniferous sandstone, 1,900 m below ground with around 15% porosity and 10 md permeability.

Three state-of-the-art horizontal CO2 injection wells were drilled perpendicular to the stress field, and therefore the dominant fracture orientation, to maximize the injection capacity.

By the end of 2008, over 2.5 million tonnes of CO2 had been stored underground. A Joint Industry Project (JIP) was set up to monitor the CO2 storage using a variety of geochemical, geophysical, and production techniques over an initial 5-year period.

In Salah monitoring results

Monitoring data include geological, geochemical, geophysical, and satellite data.

Standard oil industry geological characterization data have been acquired, including wireline and LWD well logging suites, core sampling, and 3D seismic. Geochemical monitoring data collected to date include surface and soil gas monitoring, downhole gas measurements (head gas and isotubes samples), and production monitoring.

Different tracer chemicals (perfluorocarbons) have been used to "tag" the CO2 injected at each injection well so that any CO2 detected can be differentiated from the natural CO2 in the subsurface and traced back to an individual injection well. Geophysical monitoring data will gain momentum in 2009 with the deployment of a downhole geophone detector string in a dedicated well to monitor microseismic events and the first time-lapse 3D seismic survey to monitor saturation and pressure changes.

Perhaps the most valuable, and initially surprising, monitoring method so far has been the use of satellite airborne radar interferometry to detect subtle ground deformation above the injection wells.7

Permanent scatterer interferometry is a multi-interferogram approach that draws on the phase changes occurring between a series of radar images and is specifically designed to overcome the effects of atmospheric noise and thereby determine surface movement histories over periods of several years.8 Permanent scatterer interferometry gives an accuracy of around 5 mm/year and up to 1 mm/year for a longer-term average.

Surface uplift has been detected over all three of the In Salah CO2 injection wells9-11 with corresponding subsidence also observed over the gas production area. One of the first permanent scatterer interferometry datasets based on a 2-year time sequence of data9 shows the observed surface uplift rate is around 5 mm/year.

More information on the MVA project at In Salah can be found in publications cited above and those listed as bibliography under In Salah and Wright et al.

Acknowledgments

This article is based on industry data obtained and studied by the API CCS work group, and the authors thank the work group for their contributions. The authors thank their respective employers, API, ExxonMobil, and Halliburton, for their support. Special thanks also go to Rebecca Smyth, and Jiemin Lu at the Gulf Coast Carbon Center, BEG/JSG, for Fig. 2, Brian Williams at BP for permission to add content for the In Salah case history, to Iain Wright, BP, and Philip Ringrose and Statoil for writing the MVA case history on the In Salah project, and Terry Knott, BP, for content.

References

1. EOR Survey, OGJ, Apr. 21, 2008, pp. 41-59.

2. Duguid, A., Radonjic, M., Bruant, R., Mandecki, T., Scherer, G., and Celia, M., "The Effect of CO2 Sequestration on Oil Well Cements," Greenhouse Gas Technologies Conference (GHGT-7), Vancouver, BC, Sept. 5-9, 2004.

3. Smyth, R.C., Hovorka, S.D., Lu, J., Romanak, K.D., Partin, J.W., Wong, C. and Yang, C.: "Assessing risk to fresh water resources from long term CO2 injection—laboratory and field studies," paper GCCC Digital Publication Series #08-03j, 9th International Conference on Greenhouse Gas Control Technologies (GHGT-9), Washington, DC, Nov. 16-20, 2008.

4. Hovorka, S.D., Collins, D., Benson, S., Myer, L., Byrer, C. and Cohen, K.: "Update on the Frio Brine Pilot," 4th Annual Conference on Carbon Capture & Sequestration, Alexandria, Va., May 2-5, 2005

5. Koplos, J., Sham, C.H., and Ring, S.: "A Review of Injection Well Mechanical Integrity Testing Data and Implications for Geosequestration," IEA Greenhouse Gas R&D Programme 3rd Well Bore Integrity Network Meeting in Santa Fe, NM, Mar. 12-13, 2007.

6. In Salah CCS Project—MVA Case History written by Iain Wright (BP) and Philip Ringrose (StatoilHydro), Aug. 7, 2009. In addition, an article by Terry Knott on the In Salah project including the MVA work is presented at BP's web site. The same article was published in issue 23 of the BP magazine "Frontiers" on pp. 18-25, December 2008. Wright et al. paper SPE 127096 also has relevant information.

7. Mathieson, A., Wright, I., Roberts, D., and Ringrose, P.: "Satellite imaging to monitor CO2 movement at Krechba, Algeria," Energy Procedia, Vol. 1, Issue 1, February 2009, pp. 2,201-09, and Greenhouse Gas Control Technologies 9, Proceedings of the 9th International Conference on Greenhouse Gas Control Technologies (GHGT-9), Washington, DC, Nov. 16-20, 2008.

8. Vasco, D.W., and Ferretti, A.: "On the use of quasi-static deformation to understand reservoir fluid flow," Geophysics, Vol. 70, 2005, pp. 13-27.

9. Vasco, D.W., Ferretti, A., and Novali, F., "Reservoir monitoring and characterization using satellite geodetic data: Interferometric Synthetic Aperture Radar observations from the Krechba field, Algeria," paper LBNL-308E, Lawrence Berkeley National Laboratory, 2008.

10. Onuma, T., and Ohkawa, S.: "Detection of surface deformation related with CO2 injection by DInSAR at In Salah, Algeria," in Proceedings of the 9th International Conference on Greenhouse Gas Control Technologies, Nov. 16-20 2008.

11. Rutqvist, J., Birkholzer, J.T. and Chin-Fu Tsang,: "Coupled reservoir–geomechanical analysis of the potential for tensile and shear failure associated with CO2 injection in multilayered reservoir-caprock systems," paper in International Journal of Rock Mechanics and Mining Sciences, Vol. 45, Issue 2, February 2008, pp 132-143 and doi:10.1016/j.ijrmms.2007.04.006.

Bibliography

API, "Summary of Carbon Dioxide Enhanced Oil Recovery (CO2 EOR) Injection Well Technology," (www.api.org), September 2007.

Audigane, P., Gaus, I., Czernichowski, L.I., Pruess, K., and Xu., T., "Two-dimensional reactive transport modeling of CO2 injection in a saline aquifer at the Sleipner site, North Sea," American Journal of Science. 2007.

Czernichowski-Lauriol, I., and Marquette, G., "Modelling overview for CO2 storage," IEA GHG R&D Joint Network Meeting, New York, June 11-13, 2008.

Heinrich, J.J., Herzog, H.J., and Reiner, D.M. "Environmental Assessment of Geologic Storage of CO2" presented at the 2nd National Conference on Carbon Sequestration, Washington, DC, May 5-8 (2003).

Wright, I., Mathieson, A., and Ringrose, P.: "An Overview of Active Large-Scale CO2 Storage Projects," paper SPE 127096, SPE International Conference on CO2 Capture, Storage and Utilization, San Diego, Nov. 2-4, 2009.

The authors

More Brand Name Current Issue Articles

More Brand Name Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com