Steam distillation effects improve thin, light-oil reservoir recoveries

A study has shown that steamflooding distillation effects would improve crude recovery from thin reservoirs with less viscous crude.

Steam distillation means that steam injection will cause some volatile components of the crude to enter a vapor phase.

At present, the industry mostly uses steamflooding for exploiting heavy oil reservoirs. In recent years, however, some interest has been shown in using steamflooding for recovering crude from thinner reservoirs containing lighter crudes.1 2 One example of a successful application was a reservoir in the NPR-3 oil field in Wyoming.

The reservoir was first developed in 1922, but its primary recovery was only 5%. In 1985, steam injection started in the reservoir and by the end of 1996 the recovery had increased to 13.5% of the oil in place.3

Distillation effects

Steam distillation in porous media is an important mechanism in steamflooding, especially for thin oil reservoir.4 5

Our study showed that steam distillation of crude is not the major mechanism during steamflooding of heavy oil reservoirs and it can be ignored when crude viscosity is greater than 1,000 cp. But for steamflooding in thin, light-oil reservoirs, steam distillation of the crude becomes an important mechanism, contributing about 30% of the recovery.

The distillation effect depends mainly on crude oil properties, and reservoir temperature and pressure. In normal cases, the distillation effect is more pronounced with a lower formation pressure.

Steamflood recovery improves when the reservoir has higher remaining oil saturation after a conventional waterflood. Therefore, it is favorable to start steamflooding at an earlier stage.

The favorable effects of steam distillation include:6

- Decrease in flow resistance because of a lower gas viscosity.

- Formation of a solvent drive in the frontal zone.

- Transfer of light components in dead-end pores to the connected pores.

- Reduction in crude oil viscosity by self-dilution.

During steam injection, the evaporation pressures of crude oil and water increase with increasing temperature. When the vaporization pressures of oil and water are equal to the local reservoir pressure, the light components of crude oil will vaporize into a gaseous phase.

Simulation model

Our reservoir model used Block 7 of the Jinglou reservoir in Henan oil field as an example. The block had an initial oil in place of 280 million tonnes, and the main oil-bearing series is the third member of the Hetaoyuan formation, at a depth of 200-900 m.

The reservoir has a 30° C. temperature and a 1.0 formation pressure coefficient.

The thickness of a single layer is 1-4 m and the combined thickness is 3-10 m. The reservoir has a 0.65 net-to-gross ratio and a 75% initial oil saturation.

The reservoir contains a rock with a strong hydrophilic wettability, a 27.2-33.1% porosity, and 723-2,231 md permeability.

In general, the reservoir has good properties but with severe heterogeneity.

Table 1 shows the oil properties of five wells in Block 7 of Jinglou reservoir.

Our study involved dividing the crude oil into three pseudocomponents—light, middle, and heavy—based on steam distillation experiments.7 8

Tables 2 and 3 show the characteristics of the three pseudocomponents and the relationship between viscosity and temperature, while Table 4 shows the characteristics with different mole fractions of the three pseudocomponents.

Simulation results

Our study involved determining the sweep efficiencies of conventional waterflooding and steamflooding with or without considering the distillation effect for oil with several different viscosities, assuming a 95% water cut as the end point.

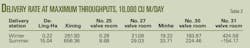

Operating parameters for the steamflood included a 0.5 steam quality, 1.2 production factor, and a 1.8 tonnes/day-hectare-m steam injection rate. Table 5 shows the displacement efficiencies.

As seen from Table 5, the conventional heavy oil (crude oil viscosity greater than 50 cp) distillation effect can improve displacement efficiency, but it is not the main mechanism. Therefore, steamflooding in heavy oil reservoirs generally ignores the effect of steam distillation, especially if the crude viscosity is greater than 1,000 cp.

For a thin oil reservoir with crude viscosity less than 50 cp, one cannot ignore the effect of steam distillation during steamflooding.

Chu showed that the distillation effect is the most important mechanism for enhancing oil recovery in steamflooding of thin oil reservoirs.9 For instance, a crude oil with a 60% distillable components has a 37% ratio of distillation effect contribution to oil recovery, a 20% increase in relative permeability with the temperature increase, and a 12% increase because of an improved sweep efficient caused by the viscosity reduction with heating.

For some lighter crude oil, the contribution of the distillation effect can reach 60%.

The laboratory simulation results showed that the relationships of steam distillation effect with the type of porous medium, steam injection rate, initial oil saturation (or the residual oil saturation after waterflood) was not obvious.

The most important internal factor is the crude oil properties, and the key external factors are the steam temperature and formation pressures.

We used a numerical stimulation to study the effects of crude oil viscosity, relative density, temperatures, pressure, and initial oil in place on distillation.

The effect of steam distillation mostly depends on the crude properties. In the normal case, a smaller relative crude density results in more distilled components. A smaller crude viscosity leads to a greater steam distillation ratio.

Figs. 1 and 2 show the effects of dead oil viscosity and density on distillation.

Table 6 shows the results of steamflooding in thin reservoirs at four water-cut stages. As seen from Table 6, an increased water saturation leads to a poorer steamflood, but the effect of the water storage volume on the distillation effect is not significant because when the water saturation increases, the corresponding oil saturation decreases.

The solvent banks formed in the steam drive process are small and the stability of the steam front becomes poor, which results in stream breaking through easily and leads to a poor steamflood.

Figs. 3 and 4 show the effect of reservoir pressure and temperature on distillation. The results indicate that steam distillation has a strong relationships with temperature and pressure, especially pressure. With a pressure increase, steam specific volume decrease sharply, so that one should decrease reservoir pressure as low as possible if the conditions allow.

Steam pressure increases with increment temperature increases. This allows for the heavy components, which cannot vaporize under low steam pressure, to vaporize as distillates.

Compared with reservoir pressure, the effect of saturation vapor temperature on distillation is not obvious. With the increment increase of steam temperature, saturation pressure correspondingly increases greatly, making the steam heat function have a much smaller increase.

Distillation plays a leading role during steamflooding in thin oil reservoirs, but pressure and waterflooding hinder the distillation effect. Therefore, for highly waterflooded reservoirs, one should first depressurize them before commencing a steamflood.

Fig. 5 shows the steam distillation effect for different steam qualities. During the thermal recovery process, the steam does not need to enter all the rock pores. Maintaining the temperature of the heat carrier can increase the heat effect.

Increasing steam quality is the main method for maintaining the temperature of the heat carrier. Regarding the thermophysical parameters of steam, steam has high latent heat of vaporization and specific volume, and the heat of high quality wet steam is greater than that of low quality wet steam. Furthermore, the energy of a vapor water molecule is greater than that of the liquid state and results in a stronger steam distillation effect.

Table 7 shows the effect of steam injection rate on steam distillation. Steam injection rate and steam injection pressure are two related parameters. Increased steam injection rate needs an increased steam injection pressure.

Increasing steam injection rate helps in reducing wellbore heat loss and improves steam quality at the bottom of the hole and thus increases steam distillation. High pressure, however, will suppress steam distillation, so that injection rate has a limited effect on steam distillation.

References

- Hoffman, B.T., and Kovscek, A., "Light-oil steam drive in fractured low- permeability reservoirs," Paper No. SPE 83491, SPE Western Regional/AAPG Pacific Section Joint Meeting, Long Beach, May 19-24 2003.

- Zhang, Y., et al., "Enhancing development efficiency of conventional reservoir by cyclical steam stimulation," Petroleum Exploration and Development, in Chinese, Vol. 31 No. 2, 2004, pp. 112-14.

- Olsen, D.K., and Sarathi, P.S, "Case history of steam injection operations at naval petroleum reserve No. 3, Teapot Dome field, Wyoming: a shallow, heterogeneous light-oil reservoir," Paper No. 25876, SPE International Thermal Operations Symposium, Bakersfield, Calif., Feb. 8-10, 1993.

- Vafaei, M.T., et al., "Analysis and simulation of steam distillation mechanism during the steam injection process," Energy & Fuels, Vol. 23, 2009, pp. 327-33.

- Verlaan, M., et al., "Experiments to investigate steam injection in light oil fractured carbonates," Paper No. SPE 113464, SPE/DOE Improved Oil Recovery Symposium, Tulsa, Apr. 20-23, 2008.

- Liu, H., et al., Principle of thermal recovery technology, in Chinese, China University of Petroleum Press, Beijing.

- Latil, M.J., and Le, P.A., "Numerical evaluation of CO2 effects in thermal oil reservoir processes," Paper No. SPE 24170, SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, Apr. 20-24, 1992.

- Hong, K.C., and Hsueh, L., "Comparison of K-value calculation methods in composition steamflood simulation," SPE Reservoir Engineering, Vol. 2, No, 2, 1997, pp. 249-57.

- Chu, C., "A comprehensive simulation study of steam flooding light-oil reservoirs after waterflood," JPT, Vol. 40, No. 7, 1988, pp. 894-904.

The authors