Kansas CBM well flow rates correlate to coal gas content

From 2001 to 2005, Quest Resource Corp. developed a set of procedures to collect, desorb, and calculate the gas contents for coal and carbonaceous shales using air rotary drill cuttings in eastern Kansas.

These procedures are fast, inexpensive, and reliable; and they can be easily completed by staff geologists in the field and in the lab. The resulting gas content data were used to make exploratory and well completion decisions in eastern Kansas.

The coal gas content data obtained from the desorption of air rotary drill cuttings were compared to the well production data. A direct correlation exists between the coal gas content and the average daily well production. In most cases, the higher the gas content of the coals, the more productive the well. Low coal gas content resulted in poorly producing wells with marginal economics.

Sample collection

From 2001 to 2008, the author collected and desorbed 1,127 air rotary drill cuttings samples from 217 wells in eastern Kansas.

Three quarters of these samples were from Quest Resource wells. The other samples were from wells drilled by SEK Energy LLC, Hopewell Operating Inc., N&B Enterprises, and Carroll Energy LLC. Another 239 samples from 55 wells are included in this study that were collected and desorbed by other Quest Resource and SEK Energy geologists in eastern Kansas.

Collection procedures

Sample collection procedures were developed by Quest geologists with the assistance of Well Refined Drilling and L&S Well Services personnel.1

With air rotary drilling rates varying from 100 to 250 ft/hr and high pressure cuttings returns, various different collection techniques were attempted.

The cuttings from a coal will normally return to the surface in less than 2 min after being drilled, and the cuttings from a 2-ft thick coal will exit the blooie line in less than 30 sec. Thus, it is absolutely necessary for the wellsite geologist to: 1) know the stratigraphy during drilling, 2) know when to expect to intersect each coal or carbonaceous shale, 3) continuously monitor the cuttings stream, 4) be prepared to collect a sample at a moment's notice, and 5) collect a high percentage of the exiting cuttings in order to obtain sufficient sample for a desorption canister.

The following sampling procedures were found to be the most effective. The wellsite geologist continuously monitors the cuttings stream at the end of the blooie line by using sieves that are either hand-held or attached to a piece of PVC pipe. A large bucket of fresh water to wash the cuttings is placed next to the end of the blooie line.

By continuously monitoring the cuttings stream and with stratigraphic data from nearby wells, the geologist is able to anticipate the next zone to be sampled. The driller assists with this process by conveying to the geologist when the drilling rate changhes.

When coal or carbonaceous shale cuttings are first observed, or are anticipated, the geologist (or a drill helper at the geologist's direction) takes an expanded metal trash can and places it over the end of the blooie line at an angle. This takes a fair degree of strength, and safety clothing (including a heavy long-sleeve shirt, boots, leather gloves, safety glasses with side shields, and hard hat) is required.

Three or more trash cans need to be available, in cases where the zone to be collected is over 2 ft in thickness. It is often necessary to rotate the trash can during collection, since the cuttings stream will quickly abrade holes in the side of the expanded metal trash can.

Sample preparation

After the sample is collected in the expanded metal trash can, it is immersed in a large bucket of drill water and agitated to remove fine cuttings and clay. Then the sample is placed in the desorption canister, packing the sample as the canister is filled to within 1⁄2-in. of the top.

If there is not sufficient sample to fill a 12-in. canister, smaller canisters (2 in., 4 in., or 6 in. in height) are used. If there is still 11⁄2 in. or more of headspace at the top of the canister after filling, it is recommended that the canister be filled to 1⁄2 in. of the top with drill water. After filling the canister, it should be placed in a cool place in the summer or in a heated vehicle in the winter, until it is transported to the laboratory for desorption. Canisters need to be stored and transported upright.

It is difficult to calculate the gas content of a mixed coal and carbonaceous shale sample. This is due to the fact that the recovered gas desorbs from both the carbonaceous shale and the coal. The Mulky coal, Croweburg coal, and Tebo coal all have overlying carbonaceous shales. Cuttings samples of these coals will always contain carbonaceous shale.

Every effort should be made to separate the coal cuttings from the carbonaceous shale before placing the sample in a canister. The coal can be separated from the carbonaceous shale by panning. The different panning methods include: 1) rotating the sample in the expanded metal trash can in the large tub of water, 2) swirling the cuttings with water in a large rubber tub, or 3) agitating the sample in a large sieve in water.

The coal, being less dense, will work its way to the top of the slurried sample, where it can be skimmed off. It is much more desirable to have a small canister (2-in. or 4-in.) filled with a high percentage of coal than a 12-in. canister filled with a mixed sample containing a small percentage of coal.

All canisters need to be pressure tested for 24+ hr prior to use. An air pump is used to pressure the canister to 15 psi, the canister is sealed, and the pressure is monitored. If there is any loss of pressure, the canister is not to be used. Leaks can be detected by immersing the pressurized canister in water.

Desorption of samples

The desorption canisters are transported to the laboratory at the end of drilling each day. Air rotary drill rigs in eastern Kansas normally drill only one shift per day.

The laboratory is kept at a constant 70º F.

The canisters are allowed to heat up-cool down to laboratory temperature before initial desorption. An inverted graduated cylinder on a ring stand is used to measure the desorbed gas. Flexible tubing is attached to each canister's valve. The graduated cylinder is moved from one group of canisters to the next to facilitate measurement of the desorbed gas.2

Initial measurements of desorbed gas are conducted 2-3 times/day, decreasing to 2-3 times/week as the desorption rate decreases. The canisters are allowed to desorb until the sample no longer is desorbing any measurable gas. This can take from 3 weeks or less to over 3 months.

No corrections were made for variations in barometric pressure, slight variations in room temperature, fluid pressure in the graduated cylinder, etc. The overall objective of this desorption is to obtain gas content data that are sufficiently accurate to be used as a screening tool to make exploratory and well completion decisions.

Calculating gas content

The desorption of cuttings will not yield gas content data as accurate as the desorption of cores.

The same collection and desorption procedures were followed in all samples collected in eastern Kansas. This resulted in gas content data that were then able to be used for comparative purposes throughout eastern Kansas.

After desorption is complete, the samples are air dried, split using a riffle splitter, and weighed. One of the main disadvantages of desorbing cuttings versus cores is that, in most cases, when collected, the cuttings samples are mixed lithologies. With samples of carbonaceous shale mixed with limestone and-or noncarbonaceous shale, a representative sample can be visually separated, each fraction weighed, and the weight of the carbonaceous shale in the total sample calculated.

All coal samples are sent to a coal laboratory where the coal is separated by flotation using a heavy liquid (specific gravity of 1.75 grams/cc) and the percentage of coal, by weight, determined.

If the coal sample contains carbonaceous shale, the percentage of the shale can be visually separated and weighed in a representative sample, in order to determine the percentage, by weight, of carbonaceous shale in the sample. A determination is then made as to what percentage of the measured gas desorbed from the coal and what percentage desorbed from the carbonaceous shale.3

Air rotary cuttings circulate to the surface very quickly, and the interval from the time that the sample is drilled to the time the cuttings are sealed in a canister is only 5 to 10 min. This negates the need to calculate the lost gas.

It is not known how much gas is released from the sample during the actual drilling process when the sample comes in contact with the high pressure percussion air hammer bit. The air rotary drill cuttings are 1⁄4 in. or less in diameter; and once desorption is complete, probably little, if any, residual gas remains.

This study

The gas content data from the desorption of 1,366 canisters from 272 wells drilled in eastern Kansas were used in this study.

Of these canisters, 492 were carbonaceous shale samples and 874 were coal samples. From 1 to 16 canisters were collected on an individual well. Either all potentially productive coals and carbonaceous shales were collected in a well (normally 6 to 10 canisters) or, due to the proximity of desorption data from nearby wells, only 1 to 3 zones were selected to be canistered.

It is not uncommon to miss collecting canister samples from individual zones for the following reasons: 1) the wellsite geologist was busy canistering a sample and missed the next sample, 2) unanticipated zones were encountered, 3) collection of insufficient sample due to various factors, including badly mixed cuttings, the drill bit pulverizing the coal, etc., and 4) unsafe collecting conditions, including excessively high air pressure, excessive water discharging from the blooie, etc.

Zones sampled

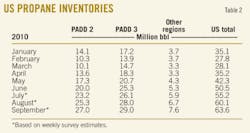

In eastern Kansas, eight carbonaceous shales and 14 coals were canistered and the gas contents calculated (Tables 1-3).

On a typical well, of these 22 zones, only 6-10 zones would be present and in sufficient thickness to sample. The sampled carbonaceous shales varied in average thickness from 1.4 to 5.2 ft and averaged 2.6 ft thick (Table 1). The coals varied in thickness from 0.6 to 2.7 ft and averaged 1.3 ft (Tables 2-3). The thickest coal sampled in an individual well was the Weir coal with a thickness of 61⁄2 ft.

The uppermost stratigraphic zone collected in eastern Kansas was the Stark shale member of the Dennis limestone in the Kansas City Group (Fig. 1 and Table 4).4 The lowest Pennsylvanian stratigraphic zone collected is the Riverton coal near the base of the Cherokee Group, just above the top of the Mississippian limestone. Desorption canisters of the Chattanooga shale have also been collected in a number of locations in eastern Kansas.

In Allen, Labette, Montgomery, Neosho, and southern Wilson counties, the zones collected ranged from the Lexington shale to the Riverton coal (Fig. 1). These zones occur over an average stratigraphic thickness of 494 ft. In northern Wilson, Woodson, and Chautauqua counties, the zones collected ranged from the Stark shale to the Riverton coal.

These zones occur over an average stratigraphic thickness of 767 ft. The shallowest zone canistered was the Summit shale at 227 ft in a well in Labette County, and the deepest zone canistered was the Riverton coal at 1,654 ft in a well in Chautauqua County.

Gas content

Table 1 summarizes the gas content data for the eight carbonaceous shales in eastern Kansas.

This table groups the gas content data by county. All of these zones are productive in various areas in eastern Kansas. The most commonly completed carbonaceous shales are the Summit, Mulky, and the Croweburg.

Tables 2 and 3 summarize the gas content data from the 14 coals sampled in eastern Kansas. Most of these coals are productive in various areas in eastern Kansas. The most commonly completed coals are the Mulky, Croweburg, Weir, Rowe, and Riverton.

Canister samples were collected from 272 wells in eastern Kansas. A complete set of all carbonaceous shales and coals (that were present in sufficient thickness) were sampled in 110 of these wells.

In these wells, 6 to 10 carbonaceous shales and coals were sampled. Table 5 summarizes the gas content data in these 110 wells. This table, listed by Kansas county, shows the range in total gas content per well and the average gas content per well. The gas content varies from a low of 1,221 to a high of 5,577 Mcf/acre with an average of 3,104 Mcf/acre.

Production correlation

A comparison was made between the coal gas content and well production. Of the 272 canistered wells in eastern Kansas, two or more coals were collected in 223 of these wells (for various reasons, not all coals that were present were canistered in every well; or in certain outlier areas, most coals were very thin or absent).

Production data

Production data for these 223 wells (with gas content data from two or more coals) was researched at the Kansas Geological Survey web site. The website lists the monthly production data on each producing gas well in eastern Kansas (most wells in eastern Kansas are multizone completions, and the gas from all zones in a well are commingled).

Of the 223 wells with gas content data on 2 or more coals, only 96 wells had sufficient production data to be included in this comparison. Most of the remaining wells had no production data or had been producing for only a short time. The wells with no production data were mostly shut-in gas wells awaiting a pipeline, and in a few cases the wells had been plugged and abandoned.

The average daily production rate was determined from each of the 96 wells. This was calculated for a 12-month period starting with the month of peak production, which occurs after a period of dewatering.

Nearly all coalbed methane wells in eastern Kansas require dewatering to be productive. This is especially true in new areas with little or no production.

In areas that have been developed and there are only infill drilling locations, this dewatering period is significantly shorter. On two thirds of the wells, peak production occurred within 7 months after the start of pumping, and peak production on the remaining one third of the wells took 8 months or longer.

Coal gas content

A weighted average gas content was calculated for the two (when only two were available) or three coals with the highest gas content for the above 96 wells.

Sixty-two wells had gas content data for three or more coals. The remaining 34 wells had gas content data for two coals. The average coal gas contents were divided into one of seven categories (Table 6). Wells, based on their average coal gas content, were sorted into their appropriate category.

Production vs. content

The daily production for all of the wells in each gas content category was averaged (Table 6). Two important conclusions can be made from Table 6. They are:

- There is, in most wells, a general correlation between coal gas content and well production. On average, gas production increases as coal gas content increases.

- There is a correlation between the coal gas content and the average daily production rate for the poorest producing well in each category. Generally, the average daily production rate for the poorest producing well in each category increases with higher gas contents.

From 2001 to 2005, Quest Resource as part of its exploration program, would lease small outlier tracts. These tracts would be 10-30 miles from established coalbed methane production in eastern Kansas.

Quest would drill one or two air rotary wells, canistering cuttings from all of the carbonaceous shale and coal zones encountered. When the results of these desorption samples indicated that the gas contents were generally poor, Quest, with minimal effort and expense, was able to redirect its exploration efforts to more productive areas.

Acknowledgments

The author thanks Quest Resource Corp., SEK Energy LLC, Carroll Energy LLC, Hopewell Operating Inc., and N&B Enterprises for permission to include company gas content data in this report. Thanks to Joe Bruns, Tom Ebers, Julie Shaffer, and Carol Shiels for reviewing drafts of this article.

References

- Ebers, M.L., "Procedures Manual—Collection and Desorption of Drill Cuttings and Calculation of Gas Contents in Carbonaceous Shales and Coals in Eastern Kansas and Northeastern Oklahoma," Quest Cherokee LLC, company report, June 2006, 10 pp.

- Darbonne, N., "Kansas—A Significant Oil and Gas Producer For More Than a Century, Kansas Continues To Offer Opportunities To Both Home-Grown and New Operators," Oil and Gas Investor, May 2005, pp. 36-44.

- Newell, K.D., "Wellsite, Laboratory, and Mathematical Techniques For Determining Sorbed Gas Content of Coals and Gas Shales Utilizing Well Cuttings," Natural Resources Research, Vol. 16, No. 1, March 2007, pp. 55-66.

- Jewett, J.M., Bayne, C.K., Goebel, E.D., O'Connor, H.G., Swineford, A., and Zeller, D.E., "The Stratigraphic Succession in Kansas," Kansas Geological Survey Bull. 189, 1968, 81 pp.

The author

Pacific Rubiales Energy Corp., Toronto, has a zone discovery at the Abanico-20 exploratory well in the northeastern part of Abanico oil field in Colombia's Upper Magdalena basin.

The well cut 113 ft of net oil pay in three Cretaceous Lower Guadalupe sandstones. It flowed 901 b/d of 22.5° gravity oil with 4.7% bs&w from 46 ft of perforations. TD is 2,986 ft MD, 1,809 ft TVD ss. Porosity averages 22.6%.

TexasGulf Coast

The Griffin Oil Unit-2 well in Gonzales County, Tex., has produced more than 33,000 bbl of oil from Cretaceous Austin chalk since being restored to production in July 2006, said Lucas Energy Inc., Houston.

Lucas Energy purchased the well for $15,000 and spent $120,000 on a pumping unit, tubing and rods, and a workover. The well had yielded 280,000 bbl before being shut-in in 2000.

Production tax is abated due to a shut-in tax exemption the company received from the state. Lucas Energy holds 100% of the working interest.