Shell installs world’s deepest production spar at Perdido

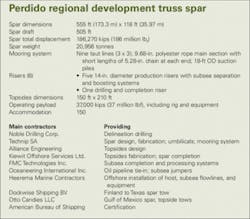

Shell Exploration & Production Co. launched the truss spar for the Perdido regional development on Aug. 8, 2008. After a 2½-day sail, it reached location at Alaminos Canyon Block 857, about 200 miles south of Freeport, Tex., about 8 miles north of the international maritime border with Mexico.

The spar was upended and attached to three of nine mooring lines (Fig. 1).

The regional spar with DVA (direct vertical access) wells is moored in about 8,000 ft of water and will gather, process, and export production from three fields: Great White, Tobago, and Silvertip, in a 15-km radius (Fig. 2).

Called the “Perdido Regional Host,” it will serve as a common processing hub; the topsides will include a rig for additional drilling and completions.

There will be 22 DVA wells from the spar, with an additional eight tiebacks from subsea completions. The spar is designed to process as much as 130,000 boe/d (100,000 bo/d and 200 MMcfd of natural gas) from wet-tree production systems. Perdido is the first Gulf of Mexico spar to have hydrocarbon storage tanks for flow assurance.

Shell is the designated operator of the Perdido development and has 35% working interest in the regional spar, along with Chevron USA Inc. (37.5%) and BP Exploration & Production Inc. (27.5%).

Russell Ford, Shell’s vice-president, Technical of E&P Americas, declined to provide the total estimated cost for the project but said about half the expenses are allocated for drilling and half for facilities.

This is the first development to reach production in the Lower Tertiary play in the Gulf of Mexico.

Water depths range 7,500-10,000 ft, and the seafloor topography is rugged along the Perdido Fold Belt.

The reservoirs have temperatures of 150-200º F. and pressures of 5,000-9,000 psi (OGJ, Nov. 6, 2006, p. 8). Shell says the oil gravity ranges 18-40º API. First oil is expected “around the end of the decade” said Shell, meaning yearend 2009.

Sail-out

The Perdido spar left Kiewit’s Ingleside, Tex., yard on Aug. 8, 2008, on a morning flood tide in clear weather. The winds were light, less than 10 knots, as the spar was towed at 2-3 knots/hr through the La Quinta channel (45 ft deep) and the Corpus Christi ship channel (53-55 ft deep). The spar’s diameter is 118 ft and it was ballasted to a draft of 31 ft (42 ft including the strakes).

Sailing between the Aransas Pass jetties by midmorning, it reached open water in the Gulf of Mexico.

M/V Devin Candies was the escort, with M/V Sidney Candies and M/V Kelly Candies towing from pad eyes on the top of the spar’s hard tank (all three US-flagged vessels from Otto Candies LLC).

Shell’s Bert Ulbricht, Perdido offshore coordination manager, told OGJ that the team planned to move the spar at 4-5 knots/hr in open water. “This is the most risky phase for the spar,” said Dale Snyder, Perdido project manager.

After a 2½-day sail across 160 km, Heerema Marine Contractors upended the spar in Alaminos Canyon Block 857, rotating it to vertical from its horizontal tow position. It took about an hour for the initial flooding to get the spar within 15º of vertical but about 20 hr to pump ballast water into the spar and get it vertical.

Heerema’s DCV Balder was already on location in Alaminos Canyon when the spar left Kiewit’s yard. It would connect the spar to the first three moorings over 10-13 days, in order to be “stormsafe,” Ulbricht said.

DCV Balder had preinstalled three polyester/chain mooring lines to seafloor anchor piles.

Shell’s Curtis Lohr, responsible for conception and design of the Perdido spar, told OGJ that this is Shell’s first use of a polyester mooring system on a production platform. The mooring lines have a 20-year design life. Incorporating polyester takes weight off the spar, reducing the vertical loading. This is one of the weight reductions that allowed Shell to use a smaller spar for the project. Lohr also said oil storage in the spar reduces the topsides weight, keeping it to a single lift.

The topsides will be completed and will sail out in February 2009, aboard the OC 4126, the largest US-flagged deck barge, and towed by Candies vessels. The topsides will be mated with the spar in a single lift using Heerema’s DCV Thialf.

Once completed, Shell says the steel spar structure will be 882 ft from the keel to the top of the drilling derrick, nearly as tall as the Eiffel Tower.

Construction

Shell chose a spar after considering FPSO and semisubmersible designs because the project needed a stable floating platform to support a platform rig in deep water. This is the first Lower Tertiary production and the Perdido reservoirs may be difficult to produce because they are highly fractured and are low-pressure. The company anticipates that a lot of well work may be required, such as sidetracks and interventions. Shell’s BC-10’s FPSO in Brazil, by comparison, has no drilling and completions rig.

Shell awarded Technip SA an engineering, procurement, and construction (EPC) contract for the Perdido production spar, umbilicals, and mooring system (OGJ, Nov. 27, 2006, p. 9). The contract covered spar and mooring system design and fabrication, which was managed through Technip’s operations and engineering center in Houston; load out onto the heavy transport vessel; transportation and quayside delivery to Kiewit’s Gulf of Mexico yard; and design of the steel catenary risers, top tension risers, and umbilicals.

Shell’s Lohr said the company ordered steel in July 2006, although the contract with Technip was not formalized until November 2006. Technip began building the spar in November 2006 at its construction yard in Pori, Finland.

The spar sailed from Finland on May 27, 2008, aboard Dockwise Shipping BV’s Mighty Servant I (Fig. 3). MS1 is a 29,000-tonne, 190-m long, heavy transport vessel.

On June 19, after a 8,200-mile sea voyage, the spar arrived at Kiewit Offshore Services 400-acre fabrication yard in Ingleside along the La Quinta shipping channel in Corpus Christi Bay.

Shell, Technip, and Kiewit completed the final outfitting in preparation for offshore installation. This included floating the spar off the Mighty Servant I, removing the seafastenings and flotation tanks, and installing the remaining strakes, anodes, and installation aids (Fig. 4).

The Perdido spar weighs 20,956 tonnes and has a total height of 173.3 m (555 ft) and a diameter of 35.97 m (118 ft).

Kiewit began building the topsides in March 2007 and will finish by February 2009. Topsides includes production equipment, drilling rig, and living quarters for 150. Snyder told OGJ the quarters are rated as a temporary refuge with fire and blast-resistant firewalls; water and foam fire-extinguishing systems cover the entire deck.

The topsides will include an Astech aluminum helideck, designed by Houston-based Zentech Inc. and supplied to Delta Engineering Corp. The helideck has an automatic fire-suppression system and a grooved surface to carry away any flammable fluids and can accommodate two long-range Sikorsky S92 helicopters simultaneously, each capable of holding up to 24 passengers and crew. Zentech Pres. Ramesh Maini said it will be the first time this type of helideck is used in the Gulf of Mexico on a US flagged vessel.

Subsea components

Snyder told OGJ that Heerema is laying the 8-in. and 10-in. subsea flowlines using its J-lay tower on the DCV Balder. It is also installing the subsea manifolds and subsea boosting system components.

In early 2008, Technip received additional contracts for engineering, fabrication, and installation of the Perdido flowlines and risers (OGJ, Feb. 18, 2008, p. 8). The work includes 8.24 miles (13.2 km) of pipelines, which Technip will weld at its spool base in Mobile, Ala. The pipelines will be delivered and installed with Technip’s Deep Blue deepwater pipelay vessel, laid to a maximum depth of 9,700 ft along the route (OGJ, Feb. 18, 2008, p. 9).

Technip also has a contract to reel-lay the 6-in. recirculation flowline from the spar to Silver Tip.

In July 2008, Shell awarded a contract to Oceaneering International Inc. to fabricate and install subsea hardware, including 29 flowline and well jumper spools, a pipeline tie-in sled, and related products. Oceaneering will begin installation later this year, using its dynamically positioned (DP) vessels, including the new Olympic Intervention IV (OI IV).

Oceaneering will perform the world's deepest (about 4,500 ft) cutting of an operating oil pipeline and splicing in a Y-connection. It will be done with ROVs and specially designed subsea tools and sleds.

Shell contracted FMC Technologies Inc. to supply the subsea completion and subsea processing systems, including 17 subsea trees (enhanced deepwater vertical trees-EVDTs) rated to 10,000 psi (69 MPa), two subsea manifolds, five subsea caisson separation and boosting systems, topside and subsea controls, and related subsea equipment.

Several new subsea technologies are being used for both BC-10 and Perdido, including subsea separation with electric submersible pumps, electrical umbilicals, and new subsea trees. The EVDTs are 5-in. by 2-in. pressure control systems with concentric production bores and retrievable choke modules with multiphase flowmeter capability.

Spars

Spars, tension-leg platforms, and semisubmersibles are all potential platforms for deepwater developments. Spars are distinct from semisubs and TLPs in that the center of gravity of a spar is always lower than the center of buoyancy, which guarantees a positive gravitational moment, making it very stable. Spars also have a different motion-control mechanism.

Spars derive no stability from their mooring systems and should not list or capsize even when completely disconnected from the moorings.

The earliest spar design had a solid caisson hull, exemplified by Neptune (1997), Genesis (1999), and Hoover-Diana (2000).

This evolved into the truss spar by replacing the lower section of the caisson hull with a truss, beginning in 2002 with spars for Boomvang, Nansen, and Horn Mountain, and followed by nine others, 2003-06.

Kikeh was the first spar installed outside the Gulf of Mexico; Murphy Oil Corp. installed it off Malaysia in 2007. Anadarko installed a cell spar on Red Hawk in 2004, in 5,300 ft water depth.

Perdido is now the world’s deepest spar installation, at 8,000 ft, 2,200 ft deeper than any other spar.

Perdido discoveries

Through July 2008, nine exploration and appraisal wells have been drilled at Great White, Tobago, and Silvertip fields.

Great White—Shell, Chevron, and BP acquired six Alaminos Canyon blocks (813, 814, 857, 858, 900, and 901) for $9.4 million in OCS Lease Sales 161 and 171 in 1996 and 1998. Great White’s ownership is Shell (33.34%), Chevron (33.33%), and BP (33.33%).

Great White field was the first of the three fields discovered, in 8,009 ft of water on Alaminos Canyon Block 857.

Shell and its JV partners used Transocean Sedco Forex’s Deepwater Nautilus semisubmersible to drill the Great White discovery well to 19,907 ft TVD, Mar. 6-May 18, 2002 (OGJ, Oct. 14, 2002, p. 8). At the time, Shell said that further drilling was required to determine commerciality.

Tobago—Unocal Corp. discovered Tobago field at Alaminos Canyon 859 in 2004, when it drilled the discovery well to 18,510 ft TD and a sidetrack to 18,425 ft, in 9,600 ft of water, at a cost of $25 million. The well had 50 ft of net pay in sandstone and was temporarily plugged (OGJ, May 10, 2004, p. 8).

At the time, Unocal had 40.01%, Shell had 30%, Chevron 16.66%, and Nexen 13.33% of Tobago (OGJ, May 10, 2004, p. 8). Tobago is now operated by Shell (32.5%) on behalf of Chevron (57.5%) and Nexen (10%; OGJ, Nov. 6, 2006, p. 8).

Silvertip—Chevron made the Silvertip discovery on Alaminos Canyon Block 815, drilling to 14,778 ft TD in 9,200 ft of water in August 2004. Chevron holds 60% and Shell 40% (OGJ, Nov. 6, 2006, p. 8).

The Perdido front-end engineering and design (FEED) started in November 2005, Snyder said. Shell did the overall FEED and managed the detailed design and construction.

In 2005, Shell signed a 2-year contract for the Noble Clyde Boudreaux semisubmersible to predrill some of the Perdido wells, starting mid-2007. The rig has dual derricks, is drilling the topholes for all 22 wells (“batch setting”), and has predrilled 8 of the wells to speed up initial production. Shell’s Ford said there is no dynamic annular pressure control—Noble is drilling at original pressure. Total depth is about 7,500 ft below the mud line.

Production

Shell designed the flowlines for Perdido at 8-in. and 10-in. nominal diameter. All flowlines except the water injection lines will be insulated. None will be heated. Production will flow to two export pipelines, requiring about 179 miles of new pipe.

Oil from Perdido will flow to Exxon’s Diana-Hoover (HOOPS) pipeline, about 70 miles away. Snyder told OGJ that adding 100,000 bo/d from Perdido will “more than double the flow” through the 18-in. diameter pipeline.

Gas will flow to the Boomvang system, more than 100 miles away. Heerema began installing the flowline tie-ins in June. The pipeline end termination (PLET) at Tobago was set in 9,600 ft of water, the deepest subsea PLET in the world.

Because of the water depth, Shell has worked on controlling hydrates. Snyder said subsea separation and boosting should take care of it, although the company will also use chemicals and will have dead oil stored in the spar that can be circulated, when necessary.

Project experience

Perdido is one of Shell’s top three deepwater projects; the others are its BC-10 development in the northern Campos basin off Espirito Santo state, Brazil (OGJ, May 5, 2008, p. 53) and Gumusut-Kakap oil field in Block J off Sabah, Malaysia.

Many of the Shell engineers on the Perdido project team have worked together on the company’s deepwater projects as far back as the Auger TLP project (Garden Banks Block 426).

Perdido is the latest of Shell’s deepwater developments in the Gulf of Mexico, including Mars, Ram-Powell, NaKika, and Ursa-Princess.