Nexen updates Long Lake SAGD project progress

Phase 1 of the Long Lake steam-assisted gravity drainage (SAGD) and upgrading project in the Athabasca region of northern Alberta continues its ramp-up, as explained in a recent Nexen Inc. presentation.

Nexen and OPTI Canada Inc. are jointly developing Long Lake. Nexen operates the SAGD portion, while OPTI is the builder and operator of the upgrader. The project is on a 63,000-acre lease.

The Long Lake project initiated first steam in the ground in mid-April 2007, with first production of synthetic crude through its upgrader anticipated late in third-quarter 2008.

The project will reach the 72,000 b/d Phase 1 full-design bitumen production capacity in 2009, according to Nexen.

Long Lake

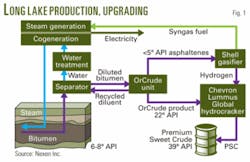

The Long Lake project is 40 km southeast of Fort McMurray and will use OPTI’s proprietary OrCrude unit in the bitumen upgrading process (Fig. 1). The OrCrude unit removes asphaltenes from the bitumen. These asphaltenes then enter a gasifier that produces a syngas fuel for steam generation and hydrogen feed for the hydrocracker.

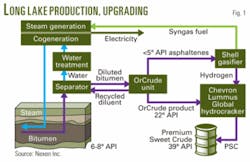

Leaving the hydrocracker is a 39° API gravity synthetic crude, called a Premium Sweet Crude (PSC). Table 1 compares PSC with West Texas Intermediate crude and Syncrude’s Sweet Premium (SSP). Besides the PSC, butane is another product coming from the upgrader. With Phase 2, the upgrader will also provide diluent, and at that time, the PSC gravity will decrease to 38° API.

When operational, the Long Lake upgrader will produce about 60,000 b/d of PSC. Nexen expects first commercial production through the upgrader in late summer 2008 with full production 12-18 months later.

Nexen says Long Lake has more than 2 billion bbl of recoverable bitumen, which translates to a production life of about 40 years once all phases are complete. The companies have applied for regulatory approval for Phase 2 that will double the upgrading capacity to 144,000 b/d, and eventually the project may produce as much as 288,000 b/d of bitumen, with completion of additional phases.

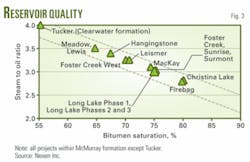

Table 2 compares the Long Lake reservoir with other reservoirs produced with SAGD.

SAGD progress

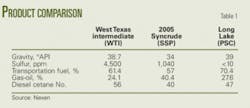

Nexen says that at the end of May 2008, 35 well pairs were in SAGD production and that the producing wells met expectations with oil rates increasing and steam-oil-ratios (SOR) decreasing (Fig. 2). A well pair consists of a horizontal lateral for steam injection drilled above a horizontal producing wellbore.

For producing the wells, the company uses gas lift as well as electric submersible pumps. As development continues, it plans to switch to ESPs for lifting bitumen from the wells.

In Phase 1, each borehole in the well pair is 800-m long and well pairs are spaced about 100-m apart. For Phase 2, the plan calls for spacing well pairs closer together at about 70 m and drilling shorter 600-m laterals.

For testing the wells, the project has grouped the wells to test separators, with typical well tests lasting 12-24 hr/well. Wells are tested twice a month. In the next phase, Nexen plans to install individual well mass flow and water-cut meters. This will provide 24 hr/day and 7 day/week surveillance of the production that can increase rapidly, according to Nexen.

After 3 months on production, the best wells produce about 500 b/d of bitumen, although average wells produce 50-100 b/d. Nexen says in a typical SAGD project, the bulk of production comes from a minority of wells.

For steam generation, the project currently uses a mix of saline and nonsaline water but will go to all saline in Phase 2. Nexen estimates that during the life of the project it will use 90% recycled water.

For the drilled well pairs, some are on SAGD and produce bitumen, while other pairs are only circulating steam. The fact that only some well pairs are on production explains why the overall SOR is June was a high 5.0, Nexen says.

In June, bitumen production averaged 10,000 b/d, and wells on production averaged an SOR less than 3.5. The company says this is in line with its long-term expectation to decrease the SOR to about 3.0. Fig 3 compares the company’s long-term SOR expectations with other SAGD projects.

In SAGD operations, the industry typically circulates steam in the well pair for 12-18 months to preheat the reservoir before production. The circulation largely heats the reservoir by conduction. Longer circulation periods allow the steam chamber to form along the entire horizontal well length to obtain better conformance. Nexen targets about 90 days of effective circulation to the toe of the horizontal. Steam at the toe ensures that latent heat is available, the company says.

Nexen also has done diesel soaks on 70% of the wells to assist conformance. It typically has injected 200-300 bbl of diesel that dissipates in the reservoir.

The wells in the commercial area have preformed much better than those in the pilot because the pilot had a much poorer quality reservoir, Nexen says

Phase 2 construction

Nexen says that construction of Phase 2 will incorporate many lessens learned during Phase 1. For Phase 2, its plan is to complete about 30% of the detailed engineering at sanction instead of the 15% completed in Phase 1. The company plans to obtain the equipment globally and fabricate the modules and to assemble them in and outside of Alberta for Phase 2. In Phase 1, it obtained the equipment globally but conducted fabrication and assembly in Alberta.

Unlike Phase 1, which had two main contractors initially and 10-15% of the work done on lump sum contracts, the company for Phase 2 plans to have multiple contracts and minimal on site lump sum contracts. It also will manage by itself more of the construction activity than in Phase 1.

To start Phase 2 construction, Nexen wants more clarity on the regulations for carbon capture so that it can include these rules in the design of the expansion. For instance, going to precombustion carbon capture with gasification would lower the volumes needed to be treated, Nexen says.

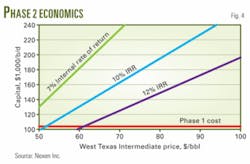

Fig. 4 shows Nexen’s Phase 2 expected internal rate of return for various oil prices and capital expenditures.