SPECIAL REPORT: World’s largest CO2 capture, EOR project planned off Dubai

Among the projects Dubai Petroleum has under way is a feasibility study for injecting CO2 to extract more oil from mature oil fields. The company expects the venture will become the world’s largest CO2 capture and EOR project.

Besides the EOR project, the company’s other plans for increasing oil and gas production off Dubai include contracting additional drilling rigs, developing a gas discovery, debottlenecking producing facilities, and optimizing reservoir performance.

Dubai Petroleum operations

Dubai Petroleum Establishment is the new state oil company that on Apr. 2, 2007, took over operations for a concession area off Dubai that previously a ConocoPhillips consortium operated since signing a concession agreement on Aug. 3, 1961.

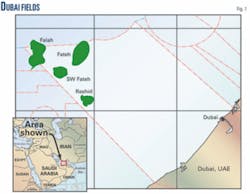

The consortium made its first oil discovery at Fateh field on June 23, 1966. Fateh lies about 160 km northwest of Dubai in the Arabian Gulf (Fig. 1).

The field is a 73 sq km folded structure, with a vertical relief of 250 m, and contains numerous carbonate reservoirs. The Cretaceous Mishrif formation carbonate reservoirs are the most prolific, having produced 60% of the oil lifted to date (Fig. 2). At Fateh, the Mishrif reservoirs are not present over the crest of the structure, due to erosion.

Other producing reservoirs include the Thamama and Ilam carbonates.

Mishrif reservoirs contain a light 33° gravity oil with 25 ppm H2S. First oil lifted from Fateh was on Sept. 22, 1969. Other fields discovered in the concession are SW Fateh on Oct. 26, 1970, Falah on Aug. 10, 1972, and Rashid on Aug. 17, 1973.

Secondary oil recovery using seawater injection commenced in the fields on June 8, 1974. Currently, the fields have about 240 active oil wells and 120 active injection wells. The oil wells produce on gas lift, with 17 compressor trains providing 1 bcfd of gas-lift capacity.

Field facilities (Fig. 3) include 71 processing, compression, water injection, and wellhead platforms, of which 4 are manned, and 317 miles of pipelines.

Final separation and storage occurs in three submerged steel vessels called “Khazzans,” which sit on the seabed. Also the Al Wasel floating storage unit provides additional storage.

Lifting of export oil is handled offshore through two single-point mooring buoys.

Dubai Petroleum says the most oil lifted in a month occurred during December 1989, with 14 million bbl lifted.

CO2 injection

Dubai Petroleum has under way a feasibility study for injecting CO2 in a miscible water-alternating-gas (WAG) scheme to extract more oil from its mature oil fields.

The company says experimental testing, in 1999, showed that WAG injection with associated gas on the western flank of Fateh field could improve oil recovery, but further investment stalled because of limited injection-gas availability.

Its new plan would capture up to 13,000 tons/day of CO2 from some onshore power plants and then compress and transport the gas for injection into offshore producing reservoirs.

The company says the project would require much investment in new offshore wellhead platforms, processing and storage facilities, and pipelines capable of handling CO2-contaminated fluids. It expects a large new revenue stream from the increased oil production with the additional benefit of storing captured CO2 in underground reservoirs at the end of the project.

If the project gets the green light, the venture would become the largest capture and injection WAG scheme in the world, with the first phase of CO2 injection commencing by yearend 2012, the company says.

Conventional drilling

Dubai Petroleum also plans to contract additional drilling rigs. Its strategy includes continuing to use the Nobel Roy Rhodes jack up drilling rig, which has been operating in the field for 19 years, to drill conventional sidetrack horizontal wells in pursuit of unexploited oil pools and has brought in a second jack up, the Mark Burns, for drilling additional wells.

It has also contracted for one hydraulic workover unit recently and expects to contract another hydraulic workover unit and jack up rig in early 2008.

By 2008, therefore, it will have five drilling units working off Dubai, something that has not been seen for many years, the company says.

Gas production

Increased energy demand in Dubai has led Dubai Petroleum to begin an aggressive program for exploiting potential gas accumulations. Its first well drilled after taking over concession operations appraised the potential gas resources in the Tertiary Asmari limestones.

The company says the well was a successful test and was hooked up for producing new lean gas in only 6 weeks after the company started operations.

First gas flowed to shore on May 23, 2007.

The company commenced in July 2007 further appraisal drilling of a potentially larger accumulation of Asmari gas at SW Fateh.

Debottlenecking

Increased production of water and lift-gas constraints limit production from some areas of the fields. Dubai Petroleum plans to eliminate these bottlenecks before drilling additional wells.

In the case of Falah field, which has a low recovery factor compared with other fields, the company has studies under way to determine the extent to which investment in electrical submersible pumps, multiphase pumps, new gas compression and export pumps, power generation, and additional separation can add production capacity.

It also has plans for extensive field tests for optimizing production in regards to high water-cut wells and gas lift.

Another project planned for 2007 and 2008 is a logging campaign targeting the under-performing Ilam reservoirs.

Company organization

Since being created, Dubai Petroleum has recruited a new staff with the skills and experience to replace the departing operating staff.

Besides staffing the general and development management sections of the organization, the company also has contracted Petrofac Management International Ltd. to handle facilities management including drilling and production operations.

The total company workforce including Petrofac employees is now about 650.

The company says that the entire transfer process from the previous operator was completed within 6 months, including the introduction of new business information systems.