Shell Alaska readies ice-class drilling units for Beaufort Sea

Shell Offshore Inc. recently renovated and upgraded two arctic-class mobile drilling units to evaluate some of its Beaufort Sea leases.

Now Shell is leading the way back to the North American Arctic. Although it’s an expensive place to work, higher prices justify the reentry, the company told OGJ in a series of exclusive interviews.

Shell was able to utilize vessels of the design originally used for the Canadian Arctic by Dome Petroleum in the 1970s. Dome’s subsidiary CanMar built three drillships and the SDC drilling barge. Gulf Canada Resources subsequently built the Kulluk conical drilling platform in 1982, the Molikpaq, and four support vessels for arctic work. In 1989-1991, Shell worked in the US Chukchi Sea using Canadian equipment.

In this latest round of work, Shell added newer technology to older vessels in order to meet higher environmental standards and enhance performance and flexibility. The Shell Kulluk drilling platform now waits in waters off the Northwest Territories and the Frontier Discoverer drillship has been standing by in Dutch Harbor (1,500 mi away in Alaska’s Aleutian Is.) for permission to drill in the US Beaufort.

Planning

The US Department of the Interior’s Minerals Management Service developed a 5-year plan for the Beaufort Sea, 2002-07, to include three oil and gas lease sales: Sale 186 in September 2003, Sale 195 in March 2005, and Sale 202 in March 2007.

The MMS ultimately awarded Shell Offshore 84 leases in the Beaufort Sea, off Alaska, based on the company’s bids in OCS Sale 195 for more than $44 million. Shell bid an additional $39 million earlier this year in OCS Sale 202.

When Shell began considering the Beaufort Sea lease sales, it had to evaluate economics, cost estimates, and feasibility of drilling. Keith Craik, Shell’s drilling engineering manager in Anchorage, said not many drilling units were available to work in arctic conditions as severe as those in the Beaufort Sea. In 2002, Shell initially considered four:

- Two CanMar Explorer drillships stacked in Singapore.

- The SDC bottom-founded drilling barge, stacked at Herschel Island, west of the Mackenzie River delta and owned by Norway’s Seatankers Ltd.

- The Kulluk drilling barge, stacked in McKinley Bay, east of the Mackenzie River delta, and owned by Seatankers.

By 2005, Craik said, attrition reduc ed the selection to the SDC and the Kulluk, although a global search turned up a few DP arctic-class ships originally built to drill in the Barents Sea. Shell needed drilling units with conventional mooring equipment, however, to work in the shallow water of the Beaufort. The company decided that the SDC did not have the water depth capability necessary to carry out the potential drilling programs.

In summer 2005, Shell sent a team to evaluate the Kulluk, consisting of Shell foremen, marine and drilling engineers, a representative from DNV, and several service company field engineers. They spent a few weeks on the rig, assessing the integrity of the hull and the marine and drilling systems. In December 2005, Shell Offshore Inc. purchased the Kulluk from Seatankers.

Two-rig strategy

While looking at the Kulluk, Shell became concerned about its ability to drill a relief well, if necessary, according to Craik. The company decided it needed a second rig for this capability and was most interested in adding a drillship.

The drillship selected was owned by Norwegian drilling contractor Frontier Drilling AS, and the company was willing to convert it to an arctic-class vessel. Shell and Frontier wrote a contract to refurbish the Frontier Discoverer drillship in late December 2005 (Fig. 1).

In January 2006, the companies signed another contract for Frontier to manage and operate the Kulluk for Shell Offshore. The primary term of both contracts is for 3 years, from July 2007, with one 5-year, optional extension.

The renovation work on the Kulluk was accomplished in place, off Canada, in McKinley Bay. The Kulluk was supplied from Inuvik, Northwest Territories, by deHavilland Twin Otter planes using an ice runway, complete with windsock and lights. By May, the runway was abandoned because of the spring thaw; crew and equipment were flown to Tuktoyaktuk, where they transited to the rig transited to the rig.

Discoverer drillship

The original hull of the Frontier Discoverer drillship, a Sonat Offshore Drilling Discoverer Class vessel, was built in 1965 at Namura Zonshno shipyard in Osaka, Japan. The ship was converted to a drillship in 1976 at Avondale Shipyards in New Orleans.

Frontier Drilling AS hired Aker Arctic in Helsinki to do the hull design and modelling required to upgrade the Discoverer hull for arctic operations. Frontier coordinated the work, which included adding sponsons to stiffen the hull, internally strengthening the bow, and adding heat tracing and insulation to exposed lines.

“We envision Discoverer working in the summer, not winter,” Craik said, when the temperatures range from -20ºF to 50ºF.

The Discoverer is turret-moored, with a symmetric, eight-point anchor pattern.

Thrusters allow the ship to rotate around the turret and face the bow into ice or weather.

The ship’s draft during transit is 8.02 m, draft-while-drilling is 7.67 m, and the mean lightship draft is 5.8 m.

The 22.2-m octagonal helideck sits aft and has room for helicopters as large as Sikorsky 61N or 92N. The Discoverer quarters can accommodate 124 persons.

Following this drilling season in the Beaufort, the Discoverer will drill some wells for Shell Exploration & Production Asia (EPA) off Australia or Malaysia.

Kulluk platform

The Kulluk arctic floating drilling platform is shaped like a large, conical donut (Fig. 2). It was designed for Gulf Canada Resources Inc.’s Beaufort Sea drilling system division by Earl and Wright Consulting Engineers in San Francisco and Lavalin. It was built in 1982 by Mitsui Engineering & Shipbuilding Co. Ltd., at Tamano Works, Japan.

Gulf Canada commissioned the purpose-built vessel to extend the drilling season in the Beaufort. It was part of a fleet of six vessels operated by the company’s arctic subsidiary, BeauDril.

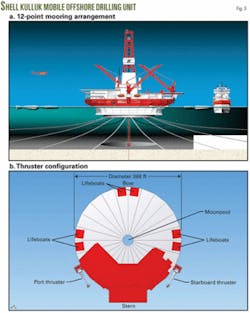

The conical-shaped hull is nearly circular in plan view and was designed to deflect ice downward (Fig. 3a). It has 24 compartments, forming 24 sides, and a double hull and bottom to prevent hull breaches and pollution.1 The 12-point mooring system was designed to resist the force of 4 ft of ice moving in any direction (Table 2).

Gulf Canada used the Kulluk to drill 12 wells at 7 locations in the Beaufort Sea from 1983-93, in 20-50 m water depths, working as early as late May to late December.

In 1992, Amoco Production Co. bought all of Gulf Canada’s drilling assets, including the Beaudril fleet.

Arco Alaska Inc. used the Kulluk to drill the Kuvlum wells in 1992-93, about 16 miles offshore and 60 miles east of Prudhoe Bay (OGJ, Oct. 11, 1993, p. 27).

In 1993, Seatankers bought the CanMar fleet, including the Kulluk.

Shell Offshore purchased the Kulluk in 2005 and retained Frontier Drilling to supervise its upgrade and refurbishment, which was completed earlier this year. The ship was renovated in place in at the Tuktoiyuk sea buoy, Canada’s McKinley Bay, in about 18 statute miles off Northwest Territories. Among the changes:

- New mud and solids control systems, including MI Swaco shakers.

- New choke manifold.

- Upgraded topdrive and iron roughneck.

- New communications system.

Bob Smith, Shell’s drilling advisor based in Houston, said that there was very little corrosion or rust, but rubber products, such as hoses and seals, had seriously deteriorated.

The Kulluk’s derrick has a catwalk, but no automated pipe-handling equipment. All drill pipe will be run as triples.

In 2006, Shell awarded a contract to Aker Arctic Technology to study and model the feasibility of adding thruster-aided propulsion to the Kulluk. The thruster design shows them installed slightly astem of midship (Fig. 3b).

Shell chose Houston’s ThrustMaster of Texas Inc. to build thrusters and hydraulic power units. This was the largest kit ever built by Thrustmaster, supervised by Shell’s marine advisor, Suman Muddusetti.

Smith said each thruster weighs about 62 tonnes and measures 62.5 ft by 13.6 ft by 10.1 ft (Fig. 4). They are full azimuth thrusters with shafts that can be rotated out of the water (90° from vertical to horizontal) when not in use. Thrusters enhance the vessel’s maneuverability and control, provide the ability to navigate between drillsites, and extend the platform’s operability in ice.

The thrusters were transported from Houston through the Panama Canal on the M/V Fennica, and installed in Canada in 2007, according to Cody Teff, Shell’s drilling superintendent for the Kulluk. He said the Kulluk will winter in Canada, although the location has not been determined.

The Kulluk has quarters for 108 persons.

Icebreaker, support

Good ice management is necessary to enhance station-keeping performance of arctic drilling units, Shell stressed to OGJ. The company has contracted two Russian icebreakers and two Finnish and Swedish-flagged anchor handling-ice management vessels to accompany the two drilling units.

The I/B Kapitan Dranitsyn, owned by the Russian Federation and operated by Murmansk Shipping Co., is the primary icebreaker assigned to the Discoverer drillship. The conventionally propelled ship was built in 1982 at the Wartsila Shipyard in Helsinki, Finland. It was remodeled in 1994, upgraded in 1999 and received a passenger vessel certificate.

The anchor-handling vessel and secondary icebreaker for the Discoverer drillship is the Finnish-flagged Fennica, owned and operated by Finstaship. Built in 1993, the Fennica is 116 m long, 26 m wide, and draws 8.4 m. This vessel has reamers on the hull, which improve turning in ice, break a wider channel, and reduce rolling and midship friction.2

The anchor-handling tug supply (AHTS) M/V Vladimir Ignatjuk is the primary icebreaker assigned to the Kulluk platform. The ship is owned by the Russian Federation and operated by Murmansk Shipping Co.

Gulf Canada built this Canadian-designed vessel in 1982 at the Victoria Yard of the Burrard Yarrrows Corp. in British Columbia. It was originally named the Arctic Kalvik when it worked in the Beaufort for Gulf Canada. It has an overall length of 88 m, breadth of 17.5 m, draft of 8.3 m, and accommodates 23 crew members. The Vladimir Ignatjuk is classified by Lloyd’s Register of Shipping as a 100 A1 icebreaker tug and LMC ice- breaking tow, ice class 1A super.

The anchor-handling vessel and secondary icebreaker for the Kulluk is the Norwegian-built AHTS M/V Tor Viking. This KMAR 808 vessel was built in 2001 and is owned and operated by Viking Supply Ships AS, based in Kristiansand, Norway, a wholly owned subsidiary of Kistefos AS. The Tor Viking is 83.7 m long, with a breadth of 18 m, and draft of 6 m.

In addition to the redundant icebreakers that protect the two drilling units, Shell has committed to three other vessels as part of its oil spill response (OSR) system, including the Affinity, an ice strengthened arctic oil tanker; the Arctic Endeavor barge with Point Barrow tug; and the Chouest Nanuq, a new, ice-strengthened resupply vessel.

The Nanuq (Inuvik for polar bear) is operated by Edison Choest Offshore, LLC, based in Pt. Barrow (Fig. 5). It was built by Choest during the past year at North American Shipbuilding in LaRose, La.

Sivulliq prospect

Shell anticipates using both the Frontier Discoverer and the Kulluk to evaluate the Sivulliq prospect in western Camden Bay, off Point Thompson. Sivulliq is in 90-110 ft water depth, about 45 miles east of Cross Island.

Sivulliq was previously called the Hammerhead prospect. The discovery well was drilled in 1985, followed by a confirmation well in 1986. MMS estimated the field contains 100-200 million bbl of oil.3

In February 1994, Shell acquired Amoco Production Co.’s majority interest in the field, reaching a 100% stake (OGJ, May 1, 1995, p. 31).

In February 2007, the MMS approved Shell’s plans to drill as many as four wells in the 2007 season, but continued court challenges have postponed drilling. Following a hearing on August 15, the 9th Circuit Court of Appeals granted an emergency stay, suspending Shell’s Beaufort operations, in order to consider antidrilling petitions from several litigants, including the Alaska Eskimo Whaling Commission and the San Francisco-based Center for Biological Diversity. The court said there was an issue as to whether the MMS had complied with the 1970 National Environmental Policy Act in granting the offshore leases to Shell.

In early December, the 9th Circuit will review the consolidated petitions and rule on the merits of the suit against the MMS. One possible outcome is lifting the injunction against drilling in the Beaufort.

Despite the setbacks in carrying out the 2007 drilling plans, Shell’s Travis Purvis, Alaska well delivery manager, said the company now intends to stay in the arctic for a long time. Alaska has become another “heartland” for Shell; “we’re back in Alaska and our intent is to stay,” he said.

References

- Lundberg, R., “Kulluk-An Ice Breaking Drilling Barge,” Oceans, Vol. 15, pp. 671-674, August 1983.

- Keinonen, Arno J., “Alaskan High Latitude Research Vessel-Concept design variations,” June 2002, University of Alaska-Fairbanks, Alaska Region Research Vessel concept design, www.sfos.uaf.edu/arrv.

- Environmental Assessment: Shell Offshore Inc. Beaufort Sea Exploration Plan, US Dept. of the Interior, Minerals Management Service, Alaska OCS Region Report, February 2007, 62 pp., www.mms.gov/alaska.