Chromatograph, equation yield usable field dewpoint prediction

Pipelines can use gas-chromatograph analysis in conjunction with an equation of state to predict hydrocarbon dewpoint in the field. This prediction method provides sufficient data resolution to enable pipeline operators to manage receipt and delivery of gas into their systems to meet hydrocarbon dewpoint specifications of downstream customers.

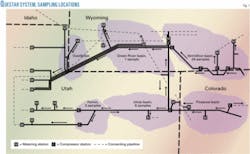

Questar Pipeline Co. monitors its pipeline system in Utah, Wyoming, and Colorado with gas chromatographs and manages the systems based on HDP. Questar used four technicians to conduct a two-phase study on dewpoint at different locations on its pipeline system.

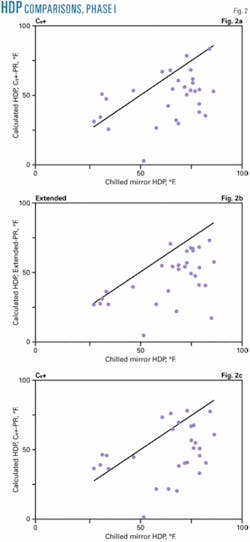

Phase I showed agreement of the dewpoint values from the C9+ analyses to the extended analyses within expected limits of about 10-12° F. for 95% of the data sets. When compared to dewpoint by chilled mirror, some of the data sets matched within the expected 10-12° F. About a third of the data sets, however, showed chilled-mirror values more than 20° F. greater than GC-EOS values.

Investigation found that the agreement between the chilled mirror and GC-EOS values were within the expected limits of 10-12° F. for Technicians 1 and 2 and that essentially all the values differing more than 20° F. were collected by Technician 4, who was apparently rushed during data collection.

Phase II used a single technician to gather additional data, showing that Peng-Robinson matched the chilled mirror somewhat better than Soave-Redlich-Kwong, but nearly all of the points agreed within 10° F.

Liquid fallout

The issue of liquid hydrocarbon formation in gas transmission lines has preoccupied the gas industry for several years. Fluctuating processing spreads (the price difference between equivalent quantities of natural gas and NGL) since 2003 have often led processing plant operators to minimize hydrocarbon liquid recoveries and enhance gas production, increasing the dewpoint of gas delivered to downstream pipelines. Deliveries of high-hydrocarbon-dewpoint gas into pipelines increase the likelihood of hydrocarbon liquid fallout, leading to concerns for both pipeline operators and their customers.

These concerns prompted formation of an industry-wide taskforce that published its findings in a white paper.1 The US Federal Energy Regulatory Commission issued a policy statement in June 2006 providing guidance to pipeline companies on how to address these gas-quality issues. Recommendations from the document formed much of the technical basis of the policy statement.

One of the key recommendations from the white paper was that a pipeline company should include a control parameter in its tariffs allowing it to limit deliveries of gas that could cause formation of liquid hydrocarbons. The white paper recommended that pipelines use cricondentherm hydrocarbon dewpoint as the control parameter because it “offered the greatest operational flexibility for all stakeholders.”

This recommendation stimulated renewed interest in dewpoint determination methods and their relative accuracies.

The theoretical dewpoint consists of any point along the dewpoint line moving from gas phase to the first small drop of liquid. The cricondentherm, or CHDP, is the maximum temperature at which hydrocarbon liquids could occur (maximum dewpoint).

This article presents a description of Questar Pipeline Co.’s use of dewpoint determination to manage liquid fallout on its system and deliver spec gas to downstream pipelines. It compares an evaluation of dewpoint using the chilled-mirror method to compositional analysis by gas chromatograph combined with an equation of state.

A C9+ analysis and an extended analysis yielded two compositional analyses. Redistributing the data from the C9+ analysis provided a third composition a (modified C6+ characterization). Field-derived gas samples from actual producing sources provided the basis for the dewpoint evaluation.

Determining dewpoints

Common methods used to determine hydrocarbon dewpoint consist of direct measurement using a chilled-mirror instrument and indirect measurement using compositional analysis from a gas chromatograph combined with an EOS. Drenker and others present an excellent review and discussion of these methods.1-8

The chilled-mirror method flows a gas stream past a mirror that is being cooled or chilled.9 The temperature at which the first condensation or dew appears on the mirror provides the dewpoint. The operator must not mistake the condensation of other substances (e.g., glycol and water) for hydrocarbon condensation.

The GC-EOS method uses a gas chromatograph for compositional analysis in conjunction with an equation of state to calculate the dewpoint as well as the cricondentherm and phase envelope. The accuracy of the method depends largely on determining the C6+ components, typically through one of two methods. The first involves a standard GC analysis for composition through C6+, using GPA 2261 procedure10 with a procedure to characterize the C6+ fractions suggested by Moshfeghian (OGJ, Nov. 21, 2005, p. 60), Voulgaris,7 and Daniels.11

The second method for C6+ determination uses either a C9+ analysis or an extended analysis of components from a GC using GPA 2286 procedures.12 Calculations typically use either a Peng-Robinson or Soave-Redlich-Kwong EOS. This article used ProMax process simulation software by Bryan Research & Engineering, Inc. for all calculations.13

GC-EOS confirmation

Warner used five certified gas standards for measurement of the dewpoint by the chilled-mirror method.3 Weight, rather than GC, determines the composition of a certified gas standard. Warner did not report the compositions for these five certified gas standards and did not use them to calculate the dewpoint by the GC-EOS method.

This article used the compositions of the five certified gases obtained from Hal Warner14 and ProMax to calculate dewpoint.

Table 1 shows that dewpoint calculated by both PR and SRK agree well with measurements by chilled mirror. The average difference for each in ProMax was -3.0 and 0.4° F., respectively. With good compositional analyses, therefore, the PR and SRK EOS options in ProMax predict dewpoint within the accuracy of the chilled-mirror method.

Based on this limited set of observations, SRK predicts dewpoint 3-4° F. higher than PR and matches the chilled-mirror measurements somewhat more closely.

Questar pipeline

Fig. 1 shows a map of Questar’s pipeline system with interconnected producing basins. The temperature-sensitive distribution loads on the west end of the system can cause gas flows to vary greatly. It is not uncommon to see several null points at any given time on the system.

Questar’s system also differs from traditional interstate pipeline systems in that portions of the system are designed and operated to handle natural gas saturated with hydrocarbon liquids. Questar installed liquid-handling facilities (pig launchers, receivers, and slug catchers) on its system, along with processing plants, to allow it to receive high-hydrocarbon-dewpoint gas and deliver processed gas to downstream markets with established hydrocarbon-dewpoint specifications.

Dewpoint management

Questar’s ability to meet dewpoint specifications depends largely on operating its straddle processing plants and is based on monitoring and managing the dewpoint of the gas that enters its pipeline system. Questar developed an online GC-EOS system to calculate dewpoint temperatures and cricondentherms automatically at various points throughout its pipelines. Questar’s fleet of chromatographs analyzes through C9+, as opposed to the industry-standard C6+.

Measured composition from the chromatographs moves to nearby flow computers where the data are stored and transmitted to Questar’s gas-control server in Salt Lake City. The compositions then feed into a dedicated server to calculate dewpoint temperatures at pipeline pressure along with cricondentherms. ProMax calculates both values. Hydrocarbon-dewpoint values are updated once every 2 min for 271 individual sample points on the system. Questar’s supervisory control and data acquisition system provides dewpoint data to its gas control and operating personnel.

Questar’s gas control and field operations monitor dewpoint data closely to help set pig launching intervals for removal of free liquids in the pipe and to help maintain the correct dewpoint temperature to downstream pipelines. Data from the dewpoint calculation system identify points with the highest dewpoint temperatures, allowing curtailment of high-hydrocarbon-dewpoint gas.

Questar’s engineers and operations personnel use the archived data to design new facilities and optimize operation of the system.

Analysis methodology

To assess the relative accuracy of the different methods of determining dewpoint, Questar conducted tests to determine the dewpoint of gas received into its system from a number of fields, using four different methods for each data set:

- Direct measurement using a chilled-mirror apparatus.

- Indirect measurement using Questar’s standard C9+ analysis and an EOS.

- Indirect measurement using an extended analysis and an EOS.

- Indirect measurement using a modified C6+ characterization and an EOS.

This modified C6+ characterization used the chromatograph results from the second of these methods, lumping all C6+ components together, and redistributing them, assuming 47% C6, 36% C7, and 17% C8 molar composition as recommended by Daniels.11

All gas-chromatograph measurements met GPA 2186-95 accuracy standards.

Measurement of the water content of the gas, along with the temperature and pressure, determined water dewpoint for each data set.

Direct measurement

Each sample location on the pipeline network saw a sample line heated to 120-140° F. and connected to a Chandler Bureau of Mines dewpoint tester. CO2 chilled the mirror of the field apparatus. Four technicians used different chilled-mirror devices to measure according to ASTM D1142 procedures.

This procedure works relatively well in most cases. On very dry gases, however, the dewpoint tester could not chill below -40° F. Calculated dewpoints for some samples lay significantly below the -40° F. obtained with the chilled-mirror apparatus. The difference between a hydrocarbon dewpoint, water dewpoint, or some other compound (e.g., glycol or compressor lube oil) forming a film on the chilled mirror proved difficult to determine.

Chromatographic analysis

The C9+ analysis groups the C6, C7, C8, and C9 by summing the area of the peaks and assigning a response factor based on the normal isomer. The on site gas analysis, which is the Questar standard C9+ analysis, used a Varian 4900 micro gas chromatograph and was performed in the field along with the chilled-mirror measurements. Technicians heated the sample delivery system to the chromatograph and the chilled mirror to 120-140° F.

Four different technicians using the same model GC performed the analyses. Each of the four Varian GCs used an 8-m capillary column and a 0.4-m Haysep A column.

Extended analysis

The extended analysis quantified a broader range of components, especially the heavier components. Questar reported BTEX (benzene, toluene, ethylbenzene, and xylene) and n-hexane along with several other compounds. It grouped other compounds in a similar manner to the C9+ analysis.

API’s 14.1 purge-and-fill method obtained spot samples in the field for extended analysis. A heated box maintained the sample cylinder at 120-140° F. until it was removed and insulated with a preheated wrap. A 36-in. extension tube kept the Joule-Thomson cooling away from the cylinder on the exit throttling device. A truck with a heated enclosure brought the cylinder back to the lab, where a heated room maintained the cylinder’s temperature at 120° F. Extended analysis used an HP6890 chromatograph with the Wasson configuration and a 60-m capillary column with a flame ionization detector.

Results

Phase 1 of this study included 34 data sets. Analysis of these results led to Phase 2, consisting of 11 data sets. Each data set included the field, sample location, pipeline pressure, water dewpoint, and various hydrocarbon dewpoints. Collecting the data for this study under typical operating conditions undoubtedly introduced more variability into the analysis but should also reflect actual pipeline conditions.

Phase 1 included five data sets with hydrocarbon dewpoints near or below the water dewpoint. Three of these five originated in the Ferron field and were apparently near or below the cooling limit of -40° F. for the chilled-mirror device. The dewpoints from both the C9+ and extended analyses also lay far below the chilled-mirror value.

The cooling limit for the chilled-mirror device or the water dewpoint appeared to interfere with the measurement of hydrocarbon dewpoint by chilled mirror for these five data sets, prompting their omission from further analysis and discussion.

Comparison of dewpoint from the C9+ analyses and the extented analyses showed about 80% of the values within 10° F. and 95% within about 12° F. for both PR and SRK. This is excellent agreement, given that the C9+ analyses were performed on site at the sample locations by four different technicians using different versions of the same Varian GC. An HP chromatograh collected, transported to the central laboratory, and analyzed the samples used in the extended analysis.

Phase 1 compared the dewpoint values from the chilled-mirror method to the values from each of the GC methods using PR (Fig. 2). The GC-SRK combination reached virtually the same results but with dewpoints 3-4° F. higher than for PR.

Roughly 30-40% of the data sets showed chilled-mirror values more than 20° F. greater than GC-EOS values. A field study such as this typically shows agreement within 10-12° F. But the excellent agreement between the C9+ and extended analyses lends credibility to the values calculated by GC-EOS.

A detailed investigation discovered differences between the samples collected by each technician. Of the 29 data sets used, Technicians 1 and 2 collected 9 sets and Technician 4 collected 20 sets. Samples collected by Technicians 1 and 2 showed agreement between the chilled mirror and GC-EOS within the expected limits of about 10-12° F., depending on the GC-EOS combination, for nearly all values, with only one greater than 20° F for certain GC-EOS combinations.

The extended analysis, as expected, gave slightly better results than the C9+, while the C6+ characterization was not as good for Technicians 1 and 2.

Agreement between chilled mirror and the GC-EOS values for Technician 4 were within the expected limit for only four to six sets, depending on GC-EOS combination, with about half differing by more than 20° F. Technican 4 collected data for 6 days; three sets were collected each day for 2 days, and four sets were collected each day for 4 days. The technician measured the hydrocarbon dewpoint for each sample by chilled mirror, ran the C9+ GC analysis in the field, and collected a gas sample for the extended GC analysis.

Technician 4 appears to have rushed and probably did not take adequate time performing the chilled-mirror measurement.

Phase II

The data problems in Phase I called about 60% of the data into question, prompting Questar to add Phase II and collect samples from 11 additional locations to supplement the original data. Technician 1 collected all the new samples from the Uinta basin, taking a chilled-mirror measurement and conducting a C9+ gas analysis.

Fig. 3 shows the results from Phase II for PR and SRK. The supplemental data showed that operator error was indeed the major cause of deviation in Phase I. The data also demonstrated the efficacy of using GC data along with an EOS to predict hydrocarbon dewpoint and CHDP in a field setting.

PR matched the data in Phase II slightly better than SRK. Out of the 11 samples taken, all but 1 were within 10° F. or less of the chilled mirror, with more than half the values within 5° F.

SRK slightly overestimated the hydrocarbon dewpoints but were still generally within an acceptable range generally.

Finding that SRK was a better predictor of hydrocarbon dewpoint using the five certified gas samples from Warner3, and that PR was the better predictor on the Uinta Basin samples, initially surprised the researchers. The entirely different nature of the samples, however, suggests that pipelines should not be limited to just one EOS for calculation purposes but rather should select one or several equations that best predict hydrocarbon dewpoint temperatures for the particular gas supplies in their systems. Both PR and SRK agreed with the chilled-mirror method in this case within acceptable limits, showing both the viability of GC-EOS methodology and the care that needs to be taken when applying it.

Acknowledgments

The authors acknowledge the help of Lili Lyddon and John Polasek of Bryan Research & Engineering, Inc. in completing this article. The authors also acknowledge Andrew Tomich and his staff at Questar Applied Technology Services for their help in collecting and preparing gas samples, performing the chromatographic analytical work, and taking the chilled-mirror dewpoint measurements used in this article.

References

- “White Paper on Liquid Hydrocarbon Drop Out in Natural Gas Infrastructure,” Natural Gas Council for the Federal Energy Regulatory Commission, NGC+ Liquid Hydrocarbon Drop Out Task Group, Feb. 28, 2005.

- Bergman, D.F., Tek, M.R., and Katz, D.L., Retrograde Condensation in Natural Gas Pipelines, Arlington, Va.: American Gas Association, 1975.

- Warner, Jr., H.R., Leamer, E.E., Spence, A.P., Bone, R.L., Hubbard, R.A., Bernos, J., and Kriel, W.A., “Hydrocarbon Dew Point Determination of Lean Natural Gases,” 80th Annual Convention of the Gas Processors Association, San Antonio, March 2001.

- “Gas Quality, Hydrocarbon Dew Point (HDP), Interchangeability,” Gas Processors Association Federal Subcommittee Issue Brief-Gas Quality, PL04-3, Feb. 3, 2005.

- Fatica, Al, “Gas-quality Debate Heats Up as More US LNG Imports Loom,” OGJ, June 14, 2004, p. 6.

- Ernest, Kevin, and Pettigrew, Douglas, “Hydrocarbon Dew Point Monitoring of Natural Gas Using Field-Mounted, On-line Gas Chromatographs,” Pipeline & Gas Journal, July 2005.

- Voulgaris, M.E., Peters, C.J., De Swan Arons, J., Derks, P.A., Janssen, R., and Smit, A.L.C., “Prediction of the Potential Hydrocarbon Liquid Content of Lean Natural Gas Comparison with Field Tests,” 73rd Gas Processors Association Annual Convention, New Orleans, Mar. 7-9, 1994.

- Drenker, Jeff, Dustman, T., Bergman, D.F., and Bullin, J.A., “An Analysis and Prediction of Hydrocarbon Dew Points and Liquids in Gas Transmission Lines,” 85th Gas Processors Association Annual Convention, Grapevine, Tex., Mar. 5-8, 2006.

- ASTM D1142-95, “Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew Point Temperature,” 2000.

- GPA 2261, “Analysis for Natural Gas and Similar Gaseous Mixtures by Gas Chromatography,” Tulsa: Gas Processors Association, 2000.

- Daniels, a Division of Emerson Electric, Standard configurations programmed into Daniels Chromatographs.

- GPA 2286, “Tentative Method of Extended Analysis for Natural Gas and Similar Gaseous Mixtures by Temperature Programmed Gas Chromatography,” Tulsa: Gas Processors Association, 1995.

- ProMax Version 1.2, Process Simulation Software by Bryan Research & Engineering, Inc., Bryan, Tex., 2005.

- Warner, Hal, private communication, Jan. 14 and Jan. 21, 2006.

The authors

Todd Dustman ([email protected]) is director of system operations analysis at Questar Pipeline Co. He has 26 years’ experience in the natural gas industry, including its pipeline, distribution, gathering, exploration, and production segments. He holds a BS (1980) in industrial engineering from the University of Utah. Dustman served on both the HDP and Interchangeability NGC+ FERC White Paper task groups.

Jeff Drenker ([email protected]) is a senior system engineer at Questar Pipeline Co. Prior to joining Questar, Drenker served as a process engineer for consulting companies specializing in coal beneficiation. He holds a BSME (1974) from the University of Idaho. He is a member of American Society of Mechanical Engineers and is a registered professional engineer in Utah.

David F. Bergman ([email protected]) is a PVT fluid consultant at BP America, in Houston. He originally worked with Amoco conducting laboratory studies. He holds a BS ChE (1970) from Michigan Technological University and MS (1971) and PhD (1976) in chemical engineering from the University of Michigan. Bergman is a member of SPE and Gas Processors Association where he is chairman of “Section F, Technical Data Development.”

Jerry A. Bullin ([email protected]) is president of Bryan Research & Engineering Inc., Bryan, Tex. He has also served as a process engineer at BS&B Process Systems and Jefferson Chemical Co. He is professor emeritus of chemical engineering at Texas A&M University. He holds BS, MS, and PhD degrees in chemical engineering from the University of Houston and is a member of American Institute of Chemical Engineers, Gas Processors Association, and American Chemical Society.