Daqing pilot shows effectiveness of high-concentration polymer flooding

A flexible development plan and careful reservoir management carried out by an integrated team succeeded in implementing a high-concentration polymer flood pilot in Daqing oil field in northern China.

Initially the field operator considered injection of high-concentration polymer to be high-risk and marginally economic. But results of the core flood experiments and a pilot project show that this technology can enhance oil recovery economically.

Enhancing oil recovery

In many cases, about 60-70% of the oil remains in the reservoir after waterflooding. This remaining oil is the target for various enhanced oil recovery methods.

According to literature,1 2 polymer flooding increases capillary numbers by only about a dozen times, which is less than the increment needed to recover residual oil. This would indicate that polymer flooding can only improve the swept volume and not the sweep efficiency.

But in recent years, many petroleum engineers consider that polymer flooding also can improve microscopic-oil displacement efficiency because of the viscoelastic properties of polymer solutions.3 4

Core flood analysis indicates that injection of a high-concentration polymer solution can increase by 20% the incremental oil recovery after waterflooding.5

Daqing undertook its high-concentration polymer flood pilot in May 2003 after completing successful pilot injectivity tests of the high-concentration (1,500-2,000 ppm and 400-500 mPa-sec viscosity) polymer fluids.

The field pilot attests to the feasibility of high-concentration polymer flooding and provides technical and practical experiences for expanding this technique to other areas of Daqing.

Only a few fields have had such high concentrations of polymer fluids injected and this pilot should become a valuable reference for designing and implementing future chemical floods, especially polymer projects.

Core floods

The core flood experiments used artificial cores with a 0.72 Dykstra-Parson coefficient and core permeability of about 1 Darcy.

The polymers investigated were hydrolyzed polyacrylamides (HPAM) with molecular weights of 17×106, 13×106, and 21×106. Crude oil mixed with kerosene simulated the formation oil. The mixture had a 9.8 mPa-sec viscosity at the 45° C. test temperature.

Brine salinity in the tests ranged from 508 to 6,778 ppm. The polymer solution was prepared with the 508-ppm brine.

The tests involved placing the cores in a thermo tank and saturating the cores with 6,778-ppm brine before injection of the simulated formation oil.

The analysis obtained initial-oil saturation after the cores were flooded with 3.0 pore volumes (PV) of simulated formation oil.

This was followed by:

• Injection of 3,700-ppm brine until the produced fluids reached an assumed economic limit of 98% water cut.

• Injection of the polymer solution slug.

• Injection of 3,700-ppm brine displacement fluid until the produced fluids reached the economic limit.

Polymer injection timing

Laboratory core-displacement experiments also determined the effect of polymer injection timing on oil recovery.

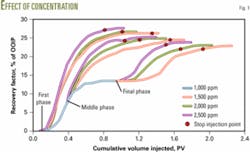

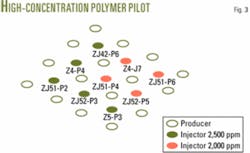

Fig. 1 illustrates that the recovery factor increases with earlier injection of high-concentration polymer solution. This suggests that a project needs to start high-concentration polymer injection as early as possible to obtain more oil recovery. To note, however, is that the timing of polymer injection is not only a technical matter but also it requires an economic feasibility study for each field individually.

For this analysis, it was assumed that the cost of chemicals used was equal to the chemical costs in surfactant-polymer-alkaline (ASP) flooding.1

Another conclusion illustrated in Fig. 1 is that the higher solution concentrations require less pore volume injected to reach the same recovery factor. Also the recovery factor does not reach the maximum when polymer injection stops, but the recovery can improve further with increased polymer injection.

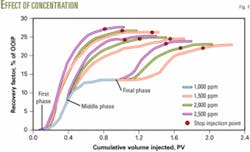

Fig. 2 shows that lower water cuts result from earlier injection of the high-concentration polymer and from higher polymer concentrations. In other words, early injection of higher polymer concentration leads to less produced fluids that need treatment.

The best polymer concentrations are in the 1,500 to 2,500-ppm range.

Molecular weight effect

Other experiments used different polymer molecular weight with a constant 2,500-ppm polymer concentration and 0.81-PV slug size.

Table 1 shows that higher molecular weight polymers obtain higher recovery factors This may be explained by the fact that higher molecular weight polymers have a higher viscoelasticity.

Higher viscoelasticity improves sweep efficiency and microscopic-oil displacement efficiency, thus increasing oil recovery.

Field pilot test

Daqing is China’s largest oil field and produces more than 900,000 bo/d from multiple sands and reservoirs. Daqing Oil Field Co. Ltd, a unit of PetroChina Co. Ltd. operates the field, which is in China’s northern Heilongjiang province.

Commercial oil from the field started in 1959, and since 1976 the field has maintained relatively stable production of 1 million bo/d until recently.

To slow the production decline, the field has implemented polymer injection as well as investigated other technologies.

Polymer flooding in the Sazhong-East part of Daqing started in 1989. As production data became available, the field expanded the polymer injection facilities and added wells.

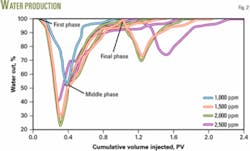

The high-concentration polymer pilot is in the Sazhong-East part. The pilot has 24 wells, consisting of 9 injectors and 16 producers (Fig. 3).

The 1.87-sq-km (460 acre) pilot produces from the PI1-7 fluvial-delta sandstone deposit. The formation initially had an 11.0-MPa (1,595 psi) pressure. Average formation permeability is 0.691 μm2, and formation net thickness is 17.9-m. Pore volume is 5.4371 million cu m (34 million bbl). The formation has a 0.723 Dykstra-Parsons coefficient.

A low-concentration polymer flood, started on May 2001. Before the start of the high-concentration polymer flood, the area had about 0.247 pore volumes of low concentration polymer solution injected, and the water cut in the central area had reached its lowest point of 65.5%.

The recovery was 42.05% of original oil in place (OOIP) for the central wells and 42.06% of OOIP for the total area.

Pilot data

Injection of high-concentration polymer solutions in the pilot started on May 2003. The injected liquid was 2,000-2,500 ppm HPAM (molecular weight 19×106). Table 2 shows the injection data for the pilot wells.

During injection, three adjustments were made:

1. On May 2004, the concentration of the injected polymer solution decreased to 1,667 ppm from 2,222 ppm and the injection rate increased from 0.1 PV/year to 0.14 PV/year.

2. On Feb. 2005, molecular weight increased to 25×106 from 19×106.

3. On May 2005, the concentration of injected polymer solution increased to 2,000 ppm from 1,667 ppm.

By the end of November 2005, cumulative production from the central area was 222,827 tons oil (1.6 million bbl), which is a 15.8% recovery of the OOIP at this stage or a cumulative 52.13% recovery of the OOIP. For the total area, cumulative recovery was 780,912 tons of oil, which is a 13.6% recovery of the OOIP at this stage and a cumulative 49.94% recovery of the OOIP.

According to numerical simulation when the water cut reaches 98%, the central area will have produced another 5.5-7.7 % of the OOIP, resulting in a 57.57-59.77% recovery of the OOIP. This prediction of recovery was based on three methods: normalized method, cumulative oil production per meter for each well, and water cut from core flooding, which showed recoveries of 19.8%, 20.7%, and 22.0%.

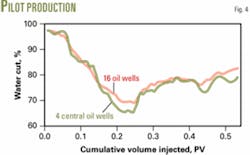

By the end of December 2005, the water cut in the central area was 79.1%. After injecting high-concentration polymer solution, the rate of the water cut increase slowed, and then the water cut decreased from a maximum of 79.6% to a minimum of 73.1% (Fig. 4).

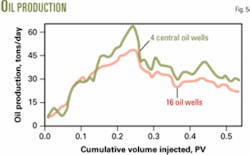

The current oil production from the central area is 29.5 tons/day (215 b/d). The daily oil production increased to a maximum of 40.5 tons from a minimum of 29.8 tons, an increase of 35.9% (Fig. 5).

The current recovery over waterflooding from the central area is already 14.3% of the OOIP. The assumed waterflooding recovery for 97-98% water cut is another 1.5% of OOIP.

The water-injection profile was largely improved after injection of the high-concentration polymer solution (Table 3).

In the case of Well Z5-P3 with the injected concentration of 2,000 ppm, the number of zones taking water increased compared to the time during which the low-concentration solution was injected (Fig. 6).

The relative water injectivity in the groups were:

• PI2-4 groups decreased to 52.9% from 76.1%.

• PI5-6 groups increased to 45.5% from 23.9%.

• PI7 group increased to 1.6% from 0.

Acknowledgment

The authors thank the management of Daqing Oilfield Ltd. Co. for permission to publish this article. ✦

References

1. Wang Demin, et al., “Actual Field Data Show that Production Costs of Polymer Flooding Can Be Lower than Water Flooding,” Paper No. SPE 84849, SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Oct. 20-21, 2003.

2. Guo Shangpin, et al., Microscopic Mechanism of Seepage Flow of Physical Chemistry Solutions, Scientific Press, Beijing, 1990.

3. Wang Demin, et al., “Viscous-Elastic Polymer Can Increase Microscale Displacement Efficiency in Cores,” Paper No. SPE 63227, SPE ATCE, Dallas, Oct. 1-4, 2000.

4. Wang Demin, et al., “Study of the Mechanism of Polymer Solution with Visco-Elastic Behavior Increasing Microscopic Oil Displacement Efficiency and the Forming of Steady ‘Oil Thread’ Flow Channels,” Paper No. SPE 68723, SPE Asia Pacific Oil and Gas Conference and Exhibition, Apr. 17-19, 2001.

5. Yang Fulin, et al., “High Concentration Polymer Flooding is Successful,” Paper No. SPE 88454, SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, Oct. 18-20, 2004.

The authors

Fulin Yang is a post-doctoral researcher in the University of Wyoming Department of Chemical and Petroleum Engineering. He previously worked as a research engineer for Daqing Oil Field Co. Ltd. His research interests include enhanced and improved oil recovery processes. Yang has a PhD in petroleum engineering from Daqing Petroleum Institute, China.

Xizhi Yang is a senior chemical engineer at the Chemical Engineering Co. of the Daqing Petroleum Administration Bureau in China. His main areas of interest include enhanced oil recovery and chemical engineering. Yang currently is studying for a PhD in petroleum engineering at the Daqing Petroleum Institute.

Jungang Li is a research engineer at the Daqing Petroleum Institute in the enhanced oil recovery section. Li has a BS from the Chengde Petroleum School.