Correlation determines gas-condensate flow through chokes

A new empirical correlation can help engineers size chokes for controlling gas-condensate production and predicting the performance of flowing wells under different conditions.

The correlation was verified with data from five gas-condensate reservoirs in Iran. The data covered a wide range of flow rates and choke sizes.

The analysis considered four forms of the correlation as a check for the data. One form correlates choke upstream pressure with liquid production rate, gas-liquid ratio, and choke size. The second uses gas production rate instead of the liquid rate. The other two forms use pressure drop across the choke instead of upstream pressure.

Five error parameters verified the accuracy of the different forms. The most accurate was the second form. The analysis checked its validity with 12 gas production rates, not considered in the development of the correlation, of 5 different wells producing from 4 gas-condensate fields.

The results show that the average absolute deviation in gas production rate for the best correlation is in the range of 0.488-9.072%.

While the formula is of a general nature, one should limit its application to the range of data presented in this study.

Choke applications

Almost all flowing wells include some form of surface restriction to regulate the flow rate. Typically, a well has a surface choke placed immediately following the wellhead. On offshore wells, a storm choke is upstream of the wellhead beneath the mud line.

Positive and adjustable chokes are the two general types of chokes used on wells.

Reasons for installing chokes in the production system include to:

• Protect the reservoir and surface equipment from pressure fluctuation.

• Maintain stable pressure downstream of the choke for processing equipment.

• Provide the necessary backpressure on a reservoir to avoid formation damage and prevent sand from entering the wellbore.

• Prevent gas or water coning.

• Control flow rates and maintain well allowable.

• Produce the reservoir at the most effective rate.

Flow through a surface choke can be either critical or subcritical.

Critical flow occurs when the velocity through the choke is greater than the sonic velocity of the fluid. This results in a mach number for the fluid that is greater than or equal to one.

For fluids with a velocity greater than sonic velocity, any downstream perturbation is unable to propagate upstream and the mass flow rate through the choke is solely a function of the upstream parameters.

Choke correlations

Although a few correlations exist for single-phase flow across chokes, these correlations are mostly for critical flow. A few other correlations attempt to model subcritical flow but fall short of their objectives.

Tangeren is among the first to publish significant findings on multiphase flow through chokes.1 The importance of his research was that it demonstrated that a compressible mixture has a critical flow velocity greater than which downstream pressure fluctuations do not propagate upstream of the choke.

Another correlation is Gilbert’s simple equation based on daily production data from a California oil field.2 Boxendall’s revised Gilbert’s equation with updated coefficients based on incremental data.3

Ros extended the theoretical work of Tangeren.4

Achong modified the Gilbert equation to match the performance of 104 wells in the Lake Maracaibo field of Venezuela.5

Several researchers have extended the treatment of choke performance beyond a purely empirical basis. Those of consequence include Ros,4 Poettmann and Beck,6 Omana,7 Fortunati,8 Ashford and Pierce,9 and Sachdeva.10

Others have developed empirical equations using field data, but none of these correlations include data from gas-condensate wells.

The production engineer should be careful in using correlations because all apply only to the ranges of fluid properties, flow rates, upstream pressure, gas-liquid ratios, and choke sizes of the field data used in their development.

Multiphase choke flow

One can write the general form of multiphase flow through chokes as Equation 1 (see equation box).

In the equation, c is a constant, while a and b are exponents determined from field data. The above equation takes one of four forms, shown as Equations 1a-1d.

In the equations, the mean diameter size is in 64th of an inch.

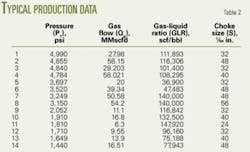

Our analysis of the four forms of the choke flow equation (Equations 1a-1d) used field data. The data were from 11 different wells producing from 5 gas-condensate reservoirs located in Iran.

Table 1 shows the range of data used in this study, while Table 2 shows the typical production data used in the calculations. In the calculations, water production is added to the oil production to obtain the liquid production rate from the well.

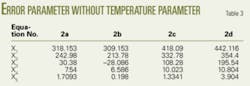

Table 3 shows the error parameter of the four forms of the correlations without including temperature as a parameter.

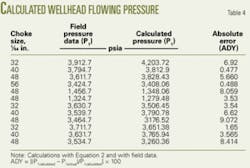

The study includes a total of 48 data points for evaluating different constants and exponents of Equations 1a-1d. Table 4 shows the results for the best correlation for 12 data points not used in developing the correlation.

The analysis used a least-square method to obtain the constant c and the exponents a and b. Thus, for gas-condesate, Equation 2a is a rewritten in the form of Equation 1.

Similarly, Equations 2b-2d rewrite the other three forms of Equation 1 with the same data and least-square method.

Equation 3 considers the effect of temperature on gas-condensate flow through chokes.

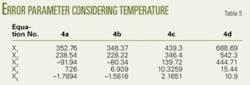

In the equation, c is a constant and one obtains exponents a, b, and d from field data. Equations 4a-4d are the four forms of correlation.

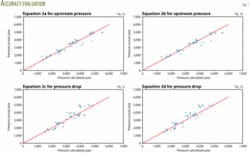

Accuracy

Studies evaluated the accuracy of each form of Equation 2 with five different error parameters (Equations 5a-5e).

Table 3 shows the results for the evaluation of Equations 2a-2d with the error parameters.

From this evaluation, one can conclude that Equation 2b has the best fit with field data while Equation 2a is the second best. Equation 2b, therefore, is the recommended equation for predicting pressure drop across a choke.

The analysis further verified the correlation by comparing the gas production rate of five different wells producing from four gas-condensate reservoirs. Table 4 shows the good agreement with 12 field-data points for a wide range of flow rates and choke sizes. The minimum and maximum average absolute deviation in gas production rate is 0.488-9.072%, respectively.

Figs. 1a and 1b show cross plots of measured upstream pressure vs. the estimated values with Equations 2a-2b. Most points fall every close to perfect correlation on the 45° line.

Figs. 1c and 1d show similar cross plots for pressure drop across the choke for Equations 2c and 2d. Again, most points fall very close to the 45° line.

The analysis also evaluated the effect of temperature on gas-condensate flow through chokes. Table 5 shows that Equation 4b is the best equation for flow calculations through chokes, although Equation 2b is more accurate than Equation 4b if the analysis does not include the temperature parameter.

Acknowledgments

The authors are grateful to Shiraz University for supporting this research. This study is also supported by Mohammad Ali Emadi, the manager of research and development for the National Iranian Oil Corp. (NIOC). ✦

References

1. Tangeren, R.E., et al., “Compressibility Effects of Two-Phase Flow,” Journal of Applied Physics, Vol. 20, No. 7, 1949, p. 637.

2. Gilbert, W.E., “Flowing and gas lift performance” API-Drilling and Production Practice, 1954.

3. Baxendall, P.B., “Bean Performance-Lake Wells,” Internal Report, October 1957.

4. Ros, N.C.J., “Theoretical Approach to the Study of Critical Gas Flow Through Beans,” Shell Internal Report, February 1959.

5. Achong, I., “Revised Bean and Performance Formula for Lake Maracaibo Wells,’’ Shell Internal Report, 1961.

6. Poettmann, F.H., and Beck, R.L., “New Charts Developed to Predict Gas-Liquid Flow Through Chokes,” World Oil, March 1963, pp. 95-101.

7. Omafia, R., et al., “Multiphase Flow Through Chokes,” Paper No. SPE 2682, SPE Annual Meeting, Denver, Sept. 28-Oct. 1, 1969.

8. Fortunati, F., ‘Two phase Flow Through Wellhead Chokes,” Paper NO. SPE 3742, SPE European Meeting, Amsterdam, May 17-18, 1972.

9. Ashford, F.E., and Pierce, P.E., “Determining Multiphase Pressure Drops and Flow Capacities in Down-Hole Safety Valves,” JPT, September 1975, pp. 1145-52.

10. Sachdeva, R., et al., ‘Two-Phase Flow Through Chokes,” Paper No. SPE 15657, SPE Annual Technical Conference and Exhibition, New Orleans, Oct. 5-8, 1986.

The authors

Feridun Esmaeilzadeh ([email protected]) is an assistant professor at Shiraz University, Shiraz, Iran. His primary research interests are gas-condensate reservoirs, supercritical fluids, phase equilibrium (EOS), simulation, and surface facility problems. He previously was with the National Iranian Oil Co. Esmaeilzadeh holds a BS in chemical engineering from Abadan Institute of Technology, an MS in chemical engineering from Shiraz University, and a PhD in chemical engineering from Sharif University of Technology.

Jawad Pirakeh is a projects lead engineer for production engineering of oil and gas fields in National Iranian Oil Co., Shiraz, Iran.

Fariba Bimakr is an MS student in chemical engineering at Shiraz University. She has a BS in chemical engineering from Mashhad Ferdowsi University.