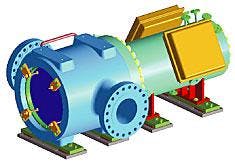

New compressor for natural gas pipeline operations

Here’s the DATUM Model C electric motor-driven compressor for natural gas pipeline uses where quiet, emission-free operations are essential.

The new compressor features an integrated, high-speed electric induction motor and modular design.

The integrated two-pole induction motor from Curtiss-Wright Corp., Roseland, NJ, uses magnetic bearings and a self-contained natural gas cooling system. The unit operates at 10 Mw with 6,900 v available at the terminals, and a maximum continuous speed of 12,000 rpm.

Its in-line piping flanges allow the compressor to be installed directly into the line in indoor or outdoor locations, helping to reduce costs for new installations and for retrofit applications. The small footprint-about 8 by 12 ft-and modular design also help make installation and maintenance easier. The in-line design helps suit it as a pipeline booster, and because of the compact size and quiet operation, it would not require the construction of a traditional pipeline station, the firm points out.

For pipeline applications, the compressor is designed with a single-stage impeller for an inlet flow of 600 MMscfd and inlet pressure of 650 psig at 60-80º F. The discharge pressure is 1,160 psig.

Because of its magnetic bearings, there is no need for an oil lubrication system, oil film seals, or dry gas seals. The unit is a completely closed system. With no gas turbine or gearbox, the system is quiet and produces no on-site emissions.It promises variable speed operation and can remain pressurized during shutdowns.

Source: Dresser-Rand Co., Box 560, Olean, NY 14760.

Saw and track system cuts any size tank, pipe

A new air-powered saw and flexible track system can be assembled to fit any size storage tank, vessel, or pipe to provide square cuts with no heat affected zone. The APS-438 air-powered saw and FlexTrack system features track sections that fit together to create a secure system that can be mounted to any size tank or pipe from 6 ft diameter up using tack welds. The firm says it produces square and accurate cuts within ±1/16 in.

Source: ESCO Tool, Box 530, Medfield, MA 02052.