Shell’s interest in enhanced oil recovery grows

As easy oil becomes more difficult to find and produce, Royal Dutch Shell PLC sees enhanced oil recovery (EOR) contributing more to the world’s growing energy needs.

Primary and secondary production methods leave about two thirds of oil in the ground, said John Barry, vice-president for unconventionals and EOR for Shell, in a recent webcast. EOR methods could produce some of this oil.

Barry estimated that the world’s existing oil fields might produce more than 500 billion bbl of oil with EOR methods that recover an additional 10% of the original oil in place.

Barry said Shell has more than 30 years of experiences in EOR processes that include:

- Reducing the viscosity contrast between oil and water with steam injection. Heat added to the reservoir reduces the oil viscosity, thereby allowing it to flow easier.

- Reducing the surface tension between oil and other fluids in the reservoir by injecting surfactants or a solvent such as carbon dioxide, thereby allowing the oil to be swept easier from the reservoir.

Barry said by 2030, EOR methods may account for about 10-15% of Shell’s oil production.

Steam projects

Shell’s EOR holdings include a 52% interest in AERA Energy LLC, which operates several steamfloods in California that produce about 100,000 b/d of oil (EOR survey OGJ, Apr. 17, 2006, p. 47). South Belridge is AERA’s largest operation, recovering about 38,000 bo/d with steam injection.

South Belridge first started producing in the 1940s with steam injection starting in the 1960s. Barry noted that the field is an example of “how long-term continuous application of emerging technologies and operational efficiency can maintain profitable EOR production.”

In South Belridge, AERA has adopted a Toyota-like approach in its operations that are more commonly associated with manufacturing than the traditional oil industry. The approach allows AERA to drill about 800 wells/year in the field while maintaining very competitive operating costs, Barry said.

Also Shell Canada Ltd. operates thermal oil recovery projects in the Peace River area of Alberta. For many years, Shell has investigated many methods for economically producing the highly viscous, 7 billion bbl in place resource on its leases in Peach River (Fig. 1); but to date, it has recovered only a small amount of this oil, about 50 million bbl, Barry said.

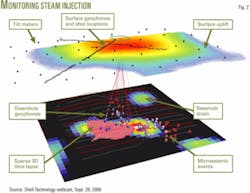

To improve the economics for producing more oil from this resource, Shell has started using such technologies as time-lapsed seismic, tilt meters, and microseismic to detect where the injected steam goes (Fig 2).

Tilt meters can detect changes on the surface of only a few millimeters as injected steam heats the subsurface formations, while microseismic uses downhole geophones to listen to the events created by the injected steam. The small noises from rock and sand grains moving around and readjusting in response to heating can indicate the direction in which steam advances through the reservoir

These technologies provide Shell a better understanding of how to inject steam efficiently and will lead to expanding the production from the area, Barry said.

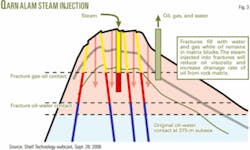

Shell also is involved with Petroleum Development Oman (PDO) in starting a steamflood in the fractured carbonate in Qarn Alam field. Most previous steamfloods have been in sandstones.

The viscous 220-cp oil in the field is mostly in the matrix that is surrounded by fractures. The field currently produces under gravity drainage that is a slow process. PDO fills the fractures with gas and the oil gradually flows from the matrix into the fractures.

By injecting steam in the fractures, PDO expects to lower the oil viscosity by a factor of about 100 to accelerate oil flow (Fig. 3). Barry said the field’s oil recovery factor should increase to 20-25% from the current 2-3% estimate.

Polymer injection

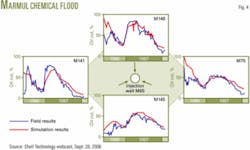

Another project in Oman will inject polymer and surfactant to enhance oil recovery in Marmul field. Barry said a pilot in the 1980s showed the effectiveness of polymer injection to increase oil recovery, but low oil prices forestalled the project’s start-up. Now that the project has been dusted off, PDO plans a 27-well development, he said.

Marmul has slightly less viscous oil than Qarn Alam and its Al-Qalata reservoir has had water injected for several years. In the 1980s, a pilot in the Al-Qalata injected water viscosified with a polymer.

Fig. 4 shows the increased crude oil cut toward yearend 1986 in the four wells around the central injector. Barry said at that time oil prices decreased to less than $10/bbl and PDO deferred the project.

In the new project, PDO plans to start polymer injections on the field’s flanks and then as soon as possible start injecting surfactants with polymer to reduce oil saturation. PDO expects to recover about 10% of the trapped oil from the field, Barry said.

Carbon dioxide

Shell was a pioneer in developing miscible CO2 flooding in the Permian basin of West Texas. Its Denver City unit is a good example of the technology’s effectiveness (Fig. 5). Shell no longer operates the flood, but CO2 flooding continues to produce an estimated 29,000 bo/d from the unit (OGJ, Apr. 17, 2006, p. 49). Occidental Permian Ltd. currently operates the CO2 flood in the unit.

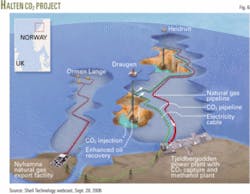

Barry said Shell and Statoil ASA have announcement a CO2 feasibility study on the Halten project off Norway (Fig. 6). Unlike the Denver City unit that uses naturally occurring CO2, a power station built in Tjeldbergodden will supply CO2 for the Hatten project.

Barry estimates that the Tjeldbergodden power plant will generate a little more than 2 million tonnes/year of CO2, which than will be injected in offshore Draugen field to increase oil production. Later the CO2 also may go to the Heidrun field further offshore.

Preliminary studies show that CO2 injection will increase oil recovery from the field by several percent, or about 50 million bbl, he said.