A new government study provides a unique, national survey of off site commercial disposal practices, methods, and costs in the major oil and gas producing states of the US.

In September 2006, Argonne National Laboratory published the report, “Off site Commercial Disposal of Oil and Gas Exploration and Production Waste: Availability, Options, and Costs.” The study was sponsored by the US Department of Energy (DOE) Office of Fossil Energy and National Energy Technology Laboratory.

In addition to identifying commercial disposal facilities for exploration and production (E&P) wastes, the report provides data on methods and costs. The study, along with a searchable database containing records for more than 200 facilities, can be accessed through the website of the Argonne’s environmental science division (www.evs.anl.gov).

Backdrop

Commercial disposal facilities are off site businesses that accept and manage E&P wastes for a fee. Typically, they are independent of oil and gas companies.

Commercial disposal facilities charge for a variety of services, including disposal and management of waste, transportation, cleaning of vehicles and tanks, disposal of wash water, and, in some cases, laboratory analysis. They use various methods for waste disposal and management.

In the US, most E&P wastes generated at onshore oil and gas wells are disposed of or otherwise managed at the well site. Under certain circumstances, operators will select off site management options. Some types of wastes are not suitable for on site management because of locations in sensitive environments. Likewise, some types of offshore drilling wastes cannot be discharged. Hence, they are either injected underground at the platform (which is not yet common in most parts of the US) or they are hauled back to shore for disposal.

What are the types and volumes of E&P wastes going to commercial disposal? According to a survey published by the American Petroleum Institute (API) in 2000, the onshore E&P segment of the US oil and gas industry generated 18.1 billion bbl of E&P wastes-149 million bbl of drilling waste, 21 million bbl of associated wastes (including completion fluids), and 17,911 million bbl of produced water during 1995.

The API survey reported that 3% (3 million bbl) of drilling wastes and about 15% (3.1 million bbl) of associated wastes were managed at off site commercial disposal facilities. The API study did not include data on the large market segment of Gulf of Mexico offshore waste materials hauled back to shore for further management.

Oil and gas companies use commercial disposal facilities for various reasons. Compliance with all applicable regulatory requirements is paramount. Several major federal laws govern waste materials and management activities:

- Resource Conservation and Recovery Act (RCRA) governs generation, transportation, storage, treatment, and disposal of solid and hazardous wastes-unless excluded or exempted.

- Clean Water Act (CWA) governs surface discharge of pollutants.

- Safe Drinking Water Act (SDWA) governs underground injection of fluids and slurries.

Federal laws and regulations generally establish minimum federal standards, while states have the lead role in the regulation of E&P and general industrial waste disposal. Most states (except California) follow the federal exemption of E&P wastes from federal hazardous waste management requirements.

Programs for regulating E&P waste management vary from state to state, reflecting the geological, climatological, ecological, topographic, economic, geographic, and age differences among oil and gas drilling and production sites across the country. In this light, a regulatory agency may not allow on site disposal for a certain type of drilling waste or a specific location within its jurisdiction.

Examples of wastes not appropriate for on site disposal include saltwater muds and very oily cuttings. Examples of sensitive environments not suitable for on site burial or land application include areas with high seasonal water tables, marshy environments, and tundra.

A second reason for sending waste to commercial facilities involves cost-effectiveness. If an operator has a relatively small volume of waste, it may make sense to send it off site rather than constructing, operating, and closing an on site facility.

Another conceivable motivation is that some operators may not want the responsibility of managing their waste and prefer to send the waste to a third party. Although this practice appears to shift the burden of responsibility and liability to the third party, the generator may still be faced with liability under the US Superfund law.

It is therefore crucial to review the business practices and compliance history of an off site commercial disposal company to minimize the risk of future liability.

Data collection occurred in two phases. In the first phase, state oil and gas regulatory officials were contacted to determine whether their agency maintained a list of permitted commercial disposal companies dedicated to oil and gas E&P waste. In the second phase, representatives of individual commercial disposal companies were interviewed to determine disposal methods and costs.

State agencies were very helpful in providing their data, to the extent available. Of 31 oil and gas producing states, 30 responded; 1 declined.

In general, most of the companies identified in the first phase willingly lent their assistance. Some cited competitive pressures and business confidentiality as primary reasons for providing cost ranges rather than snapshot figures. A few companies declined to partake in the study because they did not want to share any information with third parties.

Available facilities

States hosting off site commercial disposal companies and facilities can be divided into three basic tiers:

- Tier 1: Eight states with a dedicated, industry-specific network of off site commercial disposal companies and facilities: Arkansas, Colorado, Louisiana, New Mexico, Oklahoma, Texas, Utah, and Wyoming.

- Tier 2: Seven states with fewer off site commercial disposal companies or a produced-water-focused infrastructure of commercial disposal companies and facilities: Alabama, Michigan, Mississippi, North Dakota, Nebraska, Pennsylvania, and West Virginia.

- Tier 3: Fifteen states without industry-specific off site commercial disposal facilities or disposal companies: Alaska, Arizona, California, Florida, Illinois, Indiana, Kansas, Kentucky, Missouri, Montana, New York, Ohio, Tennessee, South Dakota, and Virginia.

Fig. 1 shows Tier 1 as a south-southwestern and mountain state zone.

Disposal methods

Bioremediation, also known as biological treatment or “biotreatment,” uses microorganisms to degrade hydrocarbon-contaminated waste biologically into nontoxic residues. Wastes are mixed with bulking agents (such as wood chips, straw, rice hulls, or husks) to increase porosity and aeration potential for biological degradation. Higher temperatures elevate metabolism of bacteria. Produced water and naturally occurring radioactive material (NORM) are not managed through bioremediation. The survey found only a few bioremediation facilities.

Landfills are used to dispose of large volumes of municipal, industrial, and hazardous wastes. Wastes suitable for burial are generally limited to solid or semisolid, low salt, low-hydrocarbon content inert materials. In certain locations, landfills accept E&P wastes only and would hence be considered monofills for E&P wastes.

Landfilling can present a very significant off site management option in states where an infrastructure of dedicated commercial disposal facilities is unavailable. Many landfills, especially those operated by large national companies, have solidification capabilities.

Burial in pits presents a traditional method of drilling-waste management. In the course of most US onshore drilling operations, the cuttings that are separated out by the shale shaker are sent to a ”reserve” pit near the drill rig. Commercial pit operations seem on the retreat, however, as indicated by the number of companies that seemed to have stopped operating, as well as the comments made by some respondents. Commercial pit disposal is still reported in western and southwestern parts of the country.

Caverns used for oil field waste disposal are created by solution mining in salt formations. Caverns are appropriate for E&P wastes because they can readily accept wastes that contain excessive levels of solids. The survey found that all cavern disposal is in Texas, although one company plans to open one in Louisiana. All waste streams are amenable to being managed by cavern disposal. One company accepts NORM.

Discharge into a surface water body under a national pollutant discharge elimination system (NPDES) permit or into a publicly owned treatment works (POTW) is occasionally used for treating and disposing produced water.

Evaporation can be used to dispose oil and gas E&P wastes in semi-arid regions of the western and southwestern US. Successful use of the technique requires that evaporation exceed the total influent to the evaporation system (including precipitation). The main evaporation technology involves the use of surface ponds.

Injection is a process in which liquids (mainly produced water) are pumped into a well and injected into porous, subsurface rock or sand formations. The fluids can include water, wastewater, or water mixed with chemicals. Oil field practices across the US have established underground injection as a viable alternative method for the disposal of these types of industrial wastes. The variant of solids injection is offered for all waste streams by one of the big commercial companies operating in Louisiana.

Land application or land farming involves the controlled and repeated application of wastes to the soil surface and use of microorganisms in the soil to biodegrade hydrocarbon constituents naturally, dilute and attenuate metals, and transform and assimilate waste constituents. It is offered in the western and southwestern parts of the country.

Recycling turns materials that would otherwise become waste into valuable resources. It is mainly offered in the case of tank bottoms reclamation.

Thermal treatments (incineration and thermal desorption) use high temperatures to reclaim or destroy hydrocarbon-contaminated material. This technology is the most efficient treatment for destroying organics. Moreover, it reduces the volume and mobility of inorganics such as metals and salts.

Waste streams high in hydrocarbons, such as oil-based muds (OBMs), are candidates for thermal treatment technology.

Other treatment technologies involve the use of cells, solidification and stabilization, and separation.

Disposal costs

Most disposal company representatives characterized their disposal fee schedules as approximate figures. The figures represent a snapshot for the survey window between October 2005 and April 2006. Thus, these costs may not reflect the actual costs that would be charged to specific customers at a given point in time.

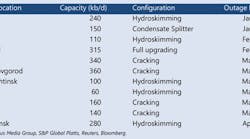

In general, the reported disposal costs vary significantly, depending on the disposal method, the host state of the disposal operations, and the degree of competition in the area. Argonne’s report presents disposal costs by waste management method and by waste stream; data can also be sorted by state:

- Disposal costs by waste management method. Table 1 shows data records sorted by waste management method-here, land application. Argonne’s report found that land application is a management method used in Arkansas (4 companies), New Mexico (12 companies), Texas (1 company), Utah (3 companies), and Wyoming (1 company).

- Disposal methods and costs by waste stream. Table 2 shows data records sorted by waste stream-here, OBMs and cuttings. Overall reported costs for disposal of OBMs and cuttings vary significantly by disposal method. Burial in landfills represents a significant disposal option for OBMs and cuttings. Land application is mainly offered in New Mexico (five companies) but also in Utah (two companies) and Wyoming (one company).

OBMs and cuttings are treated in Louisiana and Alabama (one company) and Texas (one company). Solids injection of OBMs and cuttings is undertaken by one company in Louisiana and Texas. Cavern disposal is a competitive option for OBMs and cuttings in Texas (five companies). Evaporation of OBMs and cuttings is offered in Wyoming (three companies). Burial in commercial pits, bioremediation, and recycling of OBMs and cuttings are not widely reported. Thermal treatment represents a more expensive disposal option for OBMs and cuttings.

- Disposal methods and costs by state. Table 3 shows data records sorted by state-here, New Mexico. The state oil and gas agency shared the names of 28 approved commercial disposal facilities. Most of the listed companies provided survey information. Land farming, land filling, and treatment and recycling were the prevalent disposal techniques. Costs ranged from $0.40/bbl to $18.00/bbl.

- Cost summary. Table 4 summarizes costs for all waste-management methods, all waste streams, and all states. Table 4 shows costs expressed as $/bbl. Some companies reported costs in other units; these are not repeated in Table 4.

Transportation, incidental costs

Although disposal costs are important to an operator when choosing a commercial waste disposal company, transportation and other costs weigh heavily in the final decision. Because transportation costs typically increase proportionately with distance or time from the well site to the disposal site, economic incentives exist for operators to send their wastes to disposal facilities within a reasonably short distance. Generally, operators will not be inclined to transport waste more than 50 to 75 miles, unless no other alternatives are available.

The three large disposal companies in Louisiana and Texas have established an extensive network of transfer stations along the Gulf Coast to reduce the distance that operators must transport their waste and to accommodate offshore wastes hauled back to shore. Most transportation services are offered at $55/hr to $175/hr.

Companies may also offer to contract out the transportation component. Distance, job sizes, pre-existing and long-term relationships, and surging oil prices are important factors for calculating case-specific transportation fees. Disposal companies offer trucking and roll-off service.

In cases where business is generated from offshore, companies offer barges. Hopper barges have a capacity of 6,500 bbl and are rented on a per-day or per-bbl basis.

Other issues include:

- Cleaning fees, which vary widely for trucks, boats, and containers.

- Testing-in many cases, facilities conduct laboratory tests to protect themselves.

- Paper trail-waste generators are required to fill out paperwork concerning the waste materials.

Cost ranges

Argonne’s report provides current information covering off site commercial disposal facilities. The disposal methods used across the country include bioremediation, burial, cavern, discharge, evaporation, injection, land application, recycling, thermal treatment, and treatment.

The summary cost ranges by waste type, presented below, include only per barrel cost. In nearly all cases, most costs fall within a narrower band. Multiple disposal methods are used for each type of waste. By far the most common commercial disposal method for produced water is injection.

- Contaminated soil disposal costs range from $1/bbl to $22/bbl.

- NORM disposal costs range from $150/bbl to $300/bbl. Some municipal landfills charge lower tipping fees for wastes with low levels of NORM.

- Oil-based muds and cuttings disposal costs range from $2/bbl to $40/bbl.

- Produced-water injection costs range from $0.30/bbl to $10.00/bbl but in most cases do not even reach $1.00/bbl.

- Tank-bottom disposal costs range from $0.85/bbl to $40/bbl.

- Water-based muds and cuttings disposal costs range from $0.50/bbl to $40/bbl.

When wastes are sent off site for regulatory, economic, or other reasons, operators closely examine the total cost. The most significant decision factors include actual disposal fees and transportation costs.

Acknowledgments

The project described in this article was sponsored and funded by the US Department of Energy’s Office of Fossil Energy and National Energy Technology Laboratory under contract W-31-109-Eng-38.

References

- American Petroleum Institute, Overview of Exploration and Production Waste Volumes and Waste Management Practices in the United States, prepared by ICF Consulting Group for the American Petroleum Institute, May 2000.

- Puder, M.G., and Veil, J.A., Off site Commercial Disposal of Oil and Gas Exploration and Production Waste: Availability, Options, and Costs, prepared by Argonne National Laboratory for the US Department of Energy, Office of Fossil Energy and National Energy Technology Laboratory, September 2006.

The authors

Markus G. Puder ([email protected]) is a researcher and policy analyst in the Environmental Science Division (EVS) of Argonne National Laboratory’s Washington, DC office. His legal education in the Federal Republic of Germany includes the first and second legal state examinations (German equivalent of US JD and multi-jurisdictional bar certification) and a PhD in law from the Ludwig-Maximilans University in Munich. After earning an LLM at the Georgetown University Law Center, Puder became a member of the bar of New York State and the US Supreme Court. He is an adjunct professor of law at the Georgetown University Law Center where he teaches European Union law.

John A. Veil ([email protected]) is the manager of the water policy program for Argonne National Laboratory’s Environmental Science Division (EVS). He analyzes a variety of oil and gas and electric power industry water and waste issues for the US Department of Energy. Veil has a BA in earth and planetary science from Johns Hopkins University and an MS in both zoology and civil engineering from the University of Maryland. Before joining Argonne, he managed programs for industrial wastewater discharge, underground injection, and oil control for the State of Maryland and was on the faculty of the University of Maryland.