Special Report: Controlled source electromagnetic imaging offers synergies with seismic, well-log data

Within the context of record high exploration costs and the increasing difficulty in finding large hydrocarbon deposits, exploration companies face even more pressure to reduce risk to deliver results. The challenge faced by these companies means that geoscientists and commercial managers alike must understand and incorporate the latest technologies to reduce commercial risk.

Traditionally, companies have turned to seismic surveys to understand the properties of structures they are pursuing in the search for prospects to drill. However, even with the advent of 3D acquisition over 25 years ago, in most instances seismic has only been able to answer the question of whether or not a structural trap exists. Until recently the only way to find out whether hydrocarbons are present was to drill; dry holes are still commonplace, and reservoirs with little or no seismic expression are left untested.

Over the past few years, however, more companies have taken an interest in using a new remote sensing geophysical technique to reduce risk and make more accurate inferences about what lies below the surface. It is the one technique that is able to answer the question: “Does the subsea structure contain hydrocarbons?”

Controlled Source Electromagnetic (CSEM) imaging is gaining considerable recognition as a tool for offshore exploration to detect and delineate hydrocarbons-in particular to distinguish between hydrocarbon fluids and water; a distinction that seismic data alone cannot make. At its simplest, CSEM can provide an explorer with sufficient data from which a real decision can be made.

What is CSEM?

CSEM imaging has been used for over 20 years by researchers to examine the properties of fluids in the earth, initially over active hydrothermal and volcanic systems on midocean ridges.

The technology exploits the large variation in resistivity of a formation when conductive saline water is replaced by hydrocarbon. This variation can be mapped at a local or regional scale by studying its effect on an electromagnetic field transmitted through the sea floor, giving considerable insight into the subsurface geology.

Seismic has a history of being instrumental in mapping subsurface structures and helping explorers to determine where reserves may lie, but it provides little information on the fluids within these structures. This is where OHM has seen CSEM make a large difference.

Formations that are water saturated or with low hydrocarbon saturations generally show a small CSEM response; commercially exploitable hydrocarbon deposits in general have a higher resistivity and correspondingly stronger CSEM response. Of course the presence of other resistive features, such as tight limestones or volcanic structures, can complicate the interpretation.

In all cases a presurvey assessment is made to determine whether or not a CSEM survey is appropriate, and the design of the survey must take into account what that assessment reveals. The data collection is relatively straightforward, and the real value comes in the processing and interpretation.

Dr. Lucy MacGregor, chief scientific officer with OHM, said, “This is not a one-size fits all process. Each survey must be carefully planned, taking into account the survey objectives, to ensure that the optimum dataset is collected. Postsurvey, we take great care in the analysis and interpretation to arrive at a geoelectric section or volume, providing intuitive images that the client can usefully use in their exploration process.”

The CSEM method offers exploration companies the opportunity to distinguish between water-filled and hydrocarbon-filled formations, as well as to determine the size and extent of the hydrocarbon-bearing structure. It can also provide extremely valuable information on the level of gas saturation, overcoming a pitfall in the seismic method that gives a seismic amplitude response at even very low, noncommercial gas saturations.

OHM’s advanced processing techniques produce detailed images of the location of resistive bodies than can lead explorers to identify locations of hydrocarbons. With CSEM, the subsurface geoelectric structure is revealed.

How CSEM works

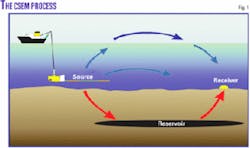

A high powered electromagnetic source is towed through the water transmitting a low-frequency signal to the seabed, and electromagnetic receivers placed on the seabed detect the resulting signal at offsets of up to 10-15 km.

Data are interpreted in one, two, and three dimensions through a combination of geophysical inversion and imaging, to provide geoelectric cross sections and volumes, and hence to map complex reservoir structures in subsurface structures anywhere from a few meters to several kilometres depth (Fig. 1).

Traditionally, CSEM surveys were limited to more than 300 m of water because of the interaction of the transmitted signals with the air in shallow water (the “airwave problem”). Research at OHM funded by a consortium that included Total, BG, Shell, Eni, and Chevron, with UK’s Industry Technology Facilitator has largely removed this limitation.

This work culminated in a successful trial on the Nuggets-1 reservoir in the UK North Sea in summer 2005 in 116 m of water, demonstrating that CSEM data could be collected in water shallower than previously thought possible.

Commercial surveys have now been completed in 70 m of water, and surveys are planned soon in even shallower water.

The methods developed have been applied to real exploration problems. In February 2006, OHM completed two surveys for Rockhopper Exploration, a company focused in the remote North Falklands basin in the South Atlantic east of Argentina. The surveys were conducted in 110-140 m of water over an untested play concept in a basin with no current production and a reputation for extremely high drilling costs.

Preliminary results of the surveys indicate the presence of resistors, which when combined with the existing seismic data, give a positive indication of hydrocarbons.

A number of other commercial surveys have been completed, all of which have achieved the survey objectives and given useful information on the presence and extent of hydrocarbons.

OHM has operated extensively in deep water clastic basins off West Africa. Surveys have also been successfully conducted in more complex geology off Brazil; in complex stratigraphic trap plays in Southeast Asia, and in technically challenging imaging conditions in the Gulf of Mexico.

Surveys off Northwest Africa have examined traps bounded by diapiric salt, and recent shallow surveys in the Falkland Islands have successfully imaged resistive bodies in settings with complex basement topography. Multiclient CSEM surveys in West Africa and off Norway are selling well and have sharply derisked investments committed by oil companies in bid rounds.

Photo courtesy of Offshore Hydrocarbon Mapping PLC.

Falklands Oil & Gas, also active in the North Falklands basin, recently selected OHM to acquire CSEM data over many of its larger prospects identified from seismic interpretation. The CSEM data will be used to reduce exploration risk and focus attention on the best prospects for drilling. The work will start in late 2006.

It seems that the largest oil companies are taking notice of this technology that is proving to be as revolutionary as 3D seismic was 25 years ago. In the August issue of the Society of Exploration Geophysicists magazine, “The Leading Edge,” ExxonMobil and Shell submitted separate articles commenting on the importance each company places on CSEM for imaging subsea-floor resistivity structure.

Exploring synergies

Imaging sea-floor resistivity structure, however, is only the first step towards quantifying the properties within a reservoir and surrounding strata.

The CSEM method is powerful in itself, but it provides only one part of the picture. By bringing together a number of complementary geophysical techniques, the strengths of each can be exploited to better constrain the properties of the rocks and fluids within.

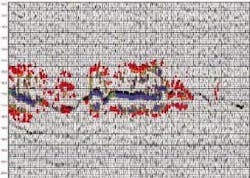

OHM has been working with Rock Solid Images Co., a private Houston concern, to develop the first-ever system that incorporates seismic, CSEM imaging, and well-log data to reduce exploration risk.

Although in the early stages of development, the techniques developed have been applied to data from the Nuggets-1 reservoir to show that through the combination of CSEM, seismic, and well-log data, gas saturation across the extent of the reservoir can be mapped (Fig. 2).

Where in the past CSEM was the domain of oil majors, we are now seeing the technology being used by midsize and junior exploration companies whose managements and shareholders recognize the value of reducing exploration risk-and therefore cost-using CSEM.

The technology is a powerful tool by itself. When combined with other geophysical technologies, CSEM offers exploration companies the chance to make better decisions and ultimately the potential to sharply reduce the risk of drilling dry exploration wells.

Extensive investment in research at OHM has improved signal to noise ratios by more than one hundredfold since the company’s founding in 2002. This has greatly enlarged the number of plays to which the technique can be applied through innovations like salt proximity imaging and technical breakthroughs like the shallow-water solution.

Although at present used largely in exploration and appraisal, the technology can be applied to reservoir monitoring and management applications.

With companies such as Falklands Oil & Gas, Rockhopper Exploration, and supermajors such as Shell, ExxonMobil, and Chevron vocally supporting CSEM and its integration with seismic technology, the question very soon might be, “Is there a business case for exploration without a CSEM survey?”

The author

Dave Pratt ([email protected]) is chief executive officer with Offshore Hydrocarbon Mapping PLC, Aberdeen, Scotland. He has more than 20 years’ experience in the oilfield service industry and was formerly president of Veritas Geophysical Services. He was vice-president of marine operations and technology for Digicon Geophysical Corp. Before that he spent more than 10 years at Racal Survey Group. A geophysicist, he has an MBA with distinction from the University of Strathclyde Graduate School of Business.