Russians study annulus cement in Arctic wells

Low water-cement ratios, heat-insulating additives, and expanded vermiculite work together to prevent formation of defective cement sheaths in Arctic wellbores.

Permafrost thickness in Russia’s Arctic fields, including Yamal, Urengoi, Yamburg, Zapolyarnoye, and others, varies from 380 to 600 m with a maximum subzero temperature of -6º C. The iciest rocks (up to 200 m thick) are formed by sandy and sandy-argillaceous deposits. Below these are loose, quasi-frozen, and low-temperature rocks that are not cemented with ice.

An analysis of problems that occur during drilling of exploratory wells shows that the formation of funnels around wellheads, drilling mud loss, longitudinal instability, and casing collapse are caused by:

- Structure and temperature inhomogeneity of permafrost along the well profile.

- Low gradient of formation fracturing; rock characteristics change when thawing.1

- Heavy caving.

- Effects of the rock “thawing-freezing” on deformation of casing.2

- Increase in absolute value and range of subzero temperature in temporarily shut-in wells due to convective heat transfer from daylight area into the space not filled with cement due to the high thermal capacity of casing.

Ensuring wellbore quality in permafrost requires that several basic requirements be observed during well construction:

- Lift cement to the wellhead behind every string.

- Prevent soil thawing when cementing.

- Form a tight cement sheath.

Hydration, hardening

The processes of Portland cement hydration and structure formation at low temperatures (above and below zero) are very slow. Below 0º C., the hydration process proceeds very slowly due to film water in thermodynamic equilibrium with ice; the cement stone structure will not form because of the ice wedging action. This is demonstrated by the results of hydration analysis of C3S-the main clinker mineral-and Portland cement in autoclave at -5º C. (Fig. 1).3 4

When the cement slurry is being frozen in closed space, pressures build up to 50 MPa. After a time, if the same sub-zero temperature is maintained, the pressure drops. Removal of the autoclave cover in “MAX,” revealed ice impregnations, although such impregnations were absent in “MIN.”

The causes of the pressure behavior are:

- Decrease in quantity of ice due to transition of highly refined water in equilibrium with ice to crystalline hydrate and adsorption water.

- Water redistribution and local pressure dispersal in a heterogeneous system due to pressure gradients of various magnitudes.

Prehardening cement at temperatures above zero causes the maximum pressure to drop considerably on subsequent freezing due to the formation of small-pore structure which has a low thermodynamic probability of forming ice.

When air-entraining admixtures or salts (antifreezes) were introduced, no pressures were noted. The phase composition of the Portland cement hydration products in water is represented as low-base hydrosilicate calcium (C-S-H), ettringite (C3ACs3H32), hexagonal calcium hydroaluminate (α-C4AH13), and lime (CH). In addition, an expanding phase Fridel salt (C3A · 3CaCl2 · H30) and calcium oxochloride (C3 · CaCl2 · H15) are formed in cement accelerator solutions (CaCl2 and NaCl).

Temperature gradient

The temperature gradient influences the formation of cement stone in the wellbore annulus. Temperature differences between internal and external casing or rock, caused, in particular, by the simultaneous influence of positive and negative (from the rock side) temperatures, result in “contraction-expansion” deformation. This includes, for instance, formation of defective structure of a cement stone and deterioration of contact in a casing-cement sheath-rock system, with lower temperatures on the outer wellbore.

More distinctly, it is revealed in water-based cement slurry (Fig. 2). The mechanism of this phenomenon is a result of heat and mass transfer. Liquid-phase slurry migrates to a zone of negative temperatures forming dendrites of ice, while solid-phase (cement particles) slurry is forced by these dendrites to the casing. As a result, a layer of cement slurry that connects with the casing is set at low water-cement factor (W/C) and higher temperature. Thus, a defective structure of the cement sheath is formed, with a distinct separation of dense and soft layers, and mobile concentric zones with a water interlayer in the zero-isotherm areas.

At the expense of stationary conditions of thermal and mass transfer, the formation of concentric zones can be observed in the process of forming a cement sheath under higher temperatures if the internal surface temperature of an annular space is higher than that on the external surface by 15-20º C.

Any attempt to use thermal methods to intensify cement hardening (heating the mixing liquid; squeezing liquid and intracasing space while waiting for cement to harden) on Arctic fields can have serious effects:

- Thawing and subsidence of terrigenous permafrost.

- Increase in water-cement factor and sharp deterioration of physical and mechanical properties of cement stone.

- Formation of freezing “water belts.”

- Formation of defective structure of the cement sheath in casing string-borehole annulus and in the drill string-casing annulus.

- Failure of contact between casing and the cement sheath after cooling due to different coefficients of thermal expansion of steel and stone.

The above factors can lead to losses in well integrity and longitudinal stability of the casing.

Cement slurry composition

Along with the temperature gradient, the composition and properties of cement slurry have a great effect on permafrost thawing and cement sheath formation in a wellbore annulus.

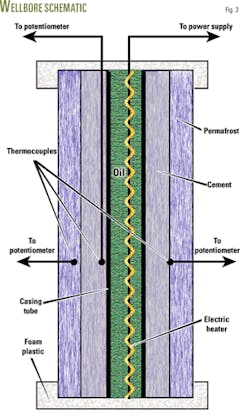

We investigated the formation of annular space using a well model inside a refrigerated chamber. The model was constructed with two coaxial cylinders with a column length-to-diameter ratio greater than 10, geometrically similar to a typical borehole (Fig. 3). Permafrost temperature in a zone adjacent to cement slurry was about +2º C. and -5º C., 2 cm apart (in massif). We maintained a preset temperature inside the casing using an electric heater for 8 hr.

We used Portland cement (GOST 1581-91) and prepared 8% calcium chloride solutions at W/C=0.5 and 0.4 (with plasticizing agent). Lightweight cement slurry with expanded vermiculite sand additive was also studied. For comparison, a standard cement slurry was tested at W/C=0.5. To avoid having the slurry freeze, we mixed with water at 20º C.

The results, in Table 1, show that standard water-based cement slurry has the greatest influence upon permafrost thawing; annular space diameter increased by 24%. Due to permafrost thawing, the W/C factor increased by 0.23 and free water volume amounted to 10.5% of the initial level of cement slurry in the column.

After the intra-casing space is heated, cement slurry gradually freezes, with the formation of concentric mobile zones according to the mechanism discussed above.

The use of calcium chloride in cement slurry led to a two-fold decrease of permafrost thawing radius and free water volume. The decrease of casing temperature to 4º C. reduced these values by a factor of three. No freezing of cement slurry adjacent to the rock was observed in this case. Additionally, there are no concentric zones in the cement stone formed at the lower casing temperature.

During testing of plasticized cement containing a complex additive, CaCl2-MLS/DEG, at W/C=0.4, a defect-free structure was formed throughout the annulus section with strong bonding of the cement stone with the casing and rock. Lightened cement slurry containing an air-entraining admixture (expanded vermiculite sand and calcium chloride) is the most effective. This material does not change borehole size and level of annulus filling. This behavior can be explained by:

- Lower temperature difference between the casing and rock.

- Sufficiently lower coefficient of thermal conductivity (0.3 W/m·K) as compared to standard cement stone (0.9-1.0 W/m·K).

High heat-insulated and relaxing properties of vermiculite-cement slurry favors the formation of stone structure in annulus (at the expense of heat accumulation), which, in turn, prevents the formation of microgaps after thermal unloading of the casing.

Result

Thus, a minimal temperature gradient between internal and external exothermic zones (Δt → 0) is necessary to prevent cement sheath destruction. This is achieved by:

- Cement hardening under absolute values of negative temperature equal or larger that that of temperature of permafrost.

- Cement mixing with ice water without heating displacing liquid.5

- Decreasing the water-cement factor and using heat-insulating additives that prevent heat transfer and accumulation of the heat of hydration in cement slurries.

References

- Goodman, M.A., “Arctic drilling operations present unique problems,” World Oil, November 1977, Vol. 185, No. 6, pp. 95-110.

- Goodman, M.A., “How permafrost thaw/freeze creates wellbore loading,” World Oil, October 1977, Vol. 185, No. 5, pp. 107-112.

- Klyusov, A.A., Lepnev, E.N., Pestov, A.A., “3CaO·SiO2 hydration in electrolyte solutions under decreased temperatures,” Journal of Applied Chemistry, Academy of Sciences of USSR, 1974, No. 11, pp. 2436-2437.

- Klyusov, A.A., “3CaO·SiO2 hydration under decreased temperatures,” Cement and Concrete Research, 1994, Vol. 24, pp. 127-132.

- American Petroleum Institute, Spec. 10: Materials and Testing for Well Cements. Appendix K: Arctic Cementing Testing Procedure, 1990, p. 89.

The authors

Anatoly Klyusov ([email protected]) is head of the well cementing and completion laboratory in the Research Institute of Natural Gases and Gas Technologies of Vniigaz Ltd., part of OAO Gazprom. He worked in Tyumen (Western Siberia) from 1968-94, as a head professor at the Plugging Material Laboratory of the Research Institute of Gas and a head of chair in the Architectural-Building Academy. Klyusov graduated from the Leningrad Technological Institute as a cement technology engineer (1963). He earned a PhD (1973) and DSc (1993) from Mendeleev Chemistry Technological Institute in Moscow. Klyusov has received the Russia State Prize and been named honor inventor of Russia. He is a fellow of the Royal Chemistry Society (Great Britain) and SPE.

Andrey A. Frolov is a general director of Burgaz Co., the drilling company of OAO Gazprom. He worked as an engineer, as deputy chief of drilling department (1989), as deputy of the general director and head of tamping department of drilling enterprise “Tyumenburgaz” (New Urengoy, 1994), and head of drilling enterprise “Orenburgburgaz” (Orenburg, 2001), before becoming general director of Burgaz Co. (2003). Frolov graduated from the Oil Institute (1988), Grozny town, USSR, specializing in technology and complex mechanization of development of oil and gas fields. He received a PhD (1997) and DSc (2001) and is a fellow of the Technological Sciences Academy.

Igor A. Klyusov ([email protected]) is a senior scientific employee of the internal field pipeline transport laboratory of Vniigaz Ltd., OAO Gazprom. He graduated from the Tyumen Oil and Gas University (1998) with a specialization in gas transport, took a postgraduate course in the Tyumen Architectural-Building Academy, and earned a PhD in drilling from the Tyumen Oil and Gas University (2001).He is a member is SPE.