CO2 sequestration: Storage capacity guideline needed

The emerging CO2 sequestration industry needs guidelines that will establish a common basis for estimating and classifying CO2 storage capacity.

Various initiatives are assessing geologic CO2 storage capacity in saline-water-bearing formations, oil and gas reservoirs, coals, and shales. Many assessments base their volumetric determinations on 100% of pore volume of a geologic unit and 100% displacement efficiency of the injection process.

While total pore volume is a starting place, guidelines would provide a more consistent basis for estimating and risk classifying CO2 storage capacity.

The petroleum industry has well established terminology for reserves and resources classification. Most data, conditions, and methodology for estimating and classifying petroleum reserves are analogous to CO2 sequestration scenarios and could serve as a basis for developing a sequestration capacity classification.

Classifications

Three primary purposes for classifying petroleum reserves are:

- Assessing available supplies by governmental agencies.

- Managing business processes for achieving exploration and production efficiency.

- Documenting the value of reserves and resources in financial statements.

Classifications differentiate estimated recoverable hydrocarbon volume from total in-place petroleum accumulation. Economically recoverable volumes are reserves classified by risk categories.

Ownership of hydrocarbon accumulations defines an energy company’s asset base and net worth, and the US Securities and Exchange Commission (SEC) regulates the reporting of reserve volumes in financial statements of publicly traded companies.

The term “recoverable” implies that hydrocarbon assessment incorporates technological and economical considerations and that existing regulatory, environmental, and political considerations do not impede production.

Proper estimates of recoverable hydrocarbons provide a comparable basis for worldwide volume estimation and distribution of oil and gas potential production that are important to government and private sector assessments.

During the last 5 years, many countries have placed increased emphasis on the potential for sequestering in geologic formations the CO2 produced from such anthropogenic sources as fossil-fueled electric generation plants, ethanol production, refineries, and cement plants. No common or widely accepted means, however, is used by the different regional organizations involved in the efforts to determine storage capacity.

Consequently, the approaches and estimates for assessing geologic storage capacity of saline-water-bearing formations, oil reservoirs, and coal seams have varied from essentially total pore-volume assessments to those that correctly include displacement efficiency and residual saturations.

A common basis for classifying CO2 storage capacity, such as the petroleum resource classification, could serve as a guideline for an emerging CO2 sequestration industry.1

This article’s objective is to begin a dialogue on this subject.

Petroleum classification

Oil and gas reserves are estimated quantities of economically recoverable petroleum from known “accumulations.” Reserves are further classified as proved, probable, or possible, based on the relative risk that the estimated volume will be produced.

The current hydrocarbon classification system has evolved over several decades. For a long period, the industry recognized definitions covering only proved reserves based on deterministic estimating methods, which was the SEC requirement for reserves reporting by publicly traded companies.

In 1987, the Society of Petroleum Engineers (SPE) issued definitions for probable and possible reserves classifications that found wide acceptance in industry.2 3 Increased offshore and frontier exploration, which located seismically defined structures but often acquired only wireline data from limited wells before making billion dollar investment decisions, created demand for probabilistic reserves estimating methods.

The SPE and World Petroleum Congress (WPC) issued new definitions in 1997 that allowed for the probabilistic estimation of reserves.2 These definitions currently are accepted widely within the worldwide petroleum industry.

In recent years, the effort has focused on expanding petroleum resource classification to cover the total resource base.

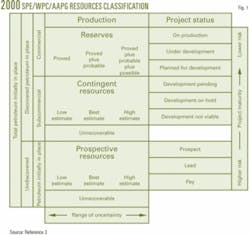

In 2000, the SPE, WPC, and American Association of Petroleum Geologists (AAPG) approved the resource classification shown in Fig. 1.3 The discovered petroleum-initially-in-place is divided into production (history), reserves (commercial), and contingent resources (subcommercial). Reserves are the main focus because they represent an asset that can be carried on company books.

All hydrocarbon volume assessments involve some uncertainty, depending on the amount of historical reservoir performance, geologic, and engineering data available at the time of the assessment and the interpretation of these data.

The 1997 SPE/WPC definitions state: “The relative degree of uncertainty may be conveyed by placing reserves into one of two principal classifications, either proved or unproved. Unproved reserves are less certain to be recovered than proved and may be further subclassified as probable and possible reserves to denote progressively increasing uncertainty in their recoverability...

“Estimation of reserves is done under conditions of uncertainty. The method of estimation is called deterministic if a single best estimate of reserves is made based on known geological, engineering, and economic data. The method of estimation is called probabilistic when the known geological, engineering, and economic data are used to generate a range of estimates and their associated probabilities.”

If the assessment uses deterministic methods, the terms “reasonable certainty” for proved, “more likely than not” for probable, and “less likely...than probable” for possible apply. With probabilistic methods, the probability that recovery will equal or exceed the estimate is set at 90% for proved, 50% for probable, and 10% for possible. The definitions give details on the type of data and conditions (geological, proof of productivity, regulatory) required for each risk category.

Both reserves and their classification are dynamic with the estimated volume or risk category changing as additional performance, engineering, and geologic data become available or as economic conditions change.

Work continues by the participating societies on enhancing the definitions. Among the issues being addressed are:

- Defining representative oil and gas pricing.

- Incorporating technological advances such as 3D seismic.

- Making the definitions more universal and in harmony with the UN framework for solid fuel and mineral classification.4

A reasonable expectation is that as definitions for CO2 sequestration capacity evolve some of these same issues will have to be addressed.

Gas storage classification

Unlike oil and gas production, natural gas storage does not have rigorously defined storage capacity classifications. The storage industry estimates the capacity pre and post-injection with regards to base or cushion gas volume and working gas volume.

Working gas is the portion of the total injected gas that is expected to be cycled (produced and injected) every season. Base gas is the portion of the total injected gas that is to remain in situ while the working gas is cycled.

In contrast to salt cavern storage of natural gas, aquifer and abandoned oil reservoir storage of natural gas in porous and permeable geologic formations is similar to the proposed CO2 storage.

In the case of the abandonment of a natural gas storage field, a portion of the base gas may also be produced through natural depletion similar to a natural gas reservoir with a water or depletion drive.

While the underground gas storage classification system appears of little use for CO2 sequestration, the storage industry has a body of knowledge that is of value, for example, testing the competency of traps and cap rocks and periodic pressure surveys to determine if any gas has been lost.

Also this industry’s experience in designing surface equipment for high-volume injection of gas could be useful in developing a CO2 sequestration industry.

CO2 storage

Financial reporting would require a rigorous CO2-sequestration-capacity classification system. Hydrocarbon reserve definitions have been thoroughly vetted for this purpose over a long period. In recent years, organizations sponsoring the definitions have worked with SEC staff to incorporate the application of advanced technology into the reserves determination.

The CO2 sequestration industry will face a similar situation in the future, perhaps with even more complex issues, such as the adsorption of CO2 on mineral surfaces or conversion of minerals to new phases fostered by the presence of CO2.

In the US, the federal government has funded the assessment of carbon sequestration as part of its efforts to develop strategies and policies for reducing greenhouse gas emissions. For CO2 sequestration to become a viable industry, companies will need risk-adjusted estimates of storage capacity volumes to develop and implement business plans.

Also, storage capacity, as an asset to the owners, likely will have reporting requirements established under the jurisdiction of the SEC for public companies. Hence, the industry will need a formal resource classification system.

The emerging CO2 sequestration industry will not have to develop an entirely new system with respect to storage-capacity classification because the current hydrocarbon-resource classification and definition system can provide an established basis from which to start. Nearly all data sources and methodologies for estimating volumes are common between petroleum and CO2 storage.

The main differences arise because CO2 storage involves the injection of substances with limited market value as compared to the extraction of a valuable commodity such as petroleum.

Common basis

The petroleum industry classifies estimated recoverable volumes of oil and gas in the ground whereas sequestration involves estimating the volume of CO2 that can be injected into a certain geological feature.

Petroleum assessments always reference the volumes to a standard condition of surface temperature and pressure regardless of the original reservoir conditions. Maximum CO2 storage capacity would depend on temperature and pressure conditions unique to each geologic feature. Reporting purposes would require both the specific temperature and pressure used for the capacity determination in addition to the volume at a common basis such as standard conditions.

Discovered vs. undiscovered

Oil and gas estimated volumes can be classified as reserves (economic and technically feasible) or contingent resources (uneconomic or not technically feasible) only for a known accumulation.

What would be the equivalent of a known accumulation for CO2 storage? Obviously evidence of both storage capacity and injectivity are required for the CO2 storage equivalent of reserves, but a definition for the equivalent for a known accumulation would have to be developed.

Determining economics

Oil and gas reserve estimators have published lists of current and future index prices that can readily be converted to wellhead prices at a specific site.

A market for CO2 exists in a limited number of oil-producing basins, while other commercial uses of CO2 in the subsurface may develop such as the use of CO2 as a base gas for underground gas storage.

In a purely CO2 sequestration scenario, CO2 availability will exceed commercial demand so that the economics of CO2 sequestration will, in most cases, involve minimizing cost rather than returning a profit. CO2 sequestration, therefore, may become a viable industry only if it is mandated by law or a system of carbon credits is established that offers an economic incentive.

CO2 producers will look for the least expensive sequestration facility. The cost to store CO2 in a particular area will depend on development cost, formation-injection capacity, distance from the source, and cost to acquire injection rights.

CO2-storage classification

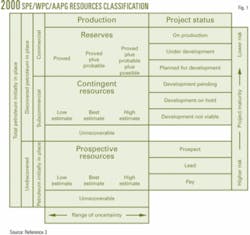

The naming convention of classifications analogous to the petroleum resource classification as endorsed by the SPE, SPEE, and WPC is a logical basis for establishing a classification system for CO2 sequestration storage capacity (Fig. 2).

Besides addressing the major differences previously discussed, the system will need to change such terms as reserves status categories of producing or nonproducing to injecting or noninjecting.

As with petroleum-recovery estimates, CO2-storage-capacity estimates will be dynamic with both the classification and volume changing with storage-site development that includes drilling new wells, well-spacing changes, or additional geological or engineering data that changes previous estimates of storage capacity.

It is beyond the scope of this article actually to propose a classification system for CO2 sequestration capacity. The industry established the first formal petroleum classification 77 years after commercial oil production began in the US (Drake’s well 1859 and API standard 1936), and it established the 90% probability standard 61 years later (SPE/WPC definitions 1997).

All the experience and knowledge gained in the development of petroleum resource definitions is available to the emerging CO2 sequestration industry. Not only is it unnecessary to reinvent the wheel, but it seems logical that those organizations currently involved in updating and expanding the hydrocarbon resource classification system would have an interest in establishing the classification system for CO2 sequestration capacity.

The SPE already has held a workshop on CO2 sequestration. The findings of this workshop along with five other related papers will be presented at the Annual Technical Conference and Exhibition in San Antonio on Sept. 27, 2006.

CO2-storage capacity

The authors’ main reason for writing this article was that they consider the storage-capacity determinations made by some organizations in the initial CO2 resource assessment to be incorrect technically.5

While the petroleum reserves definitions do not mandate specific technologies for calculating reservoir volumes, thousands of technical articles and textbooks cover the subject. Furthermore, a couple of organizations have published monographs that summarize the accepted determination methods as a supplement to the reserves definitions.2 3

Technical articles on CO2 sequestration only recently have appeared in any significant numbers. Much of the volumetric determination technology is interchangeable between petroleum and CO2. There are, however, enough differences, particularly in mineral adsorption of CO2 and dissolution of CO2 in various brine waters, that new publications should cover.

The absolute maximum CO2 storage capacity for any porous medium is the pore volume plus any mineral adsorption of CO2. This implies, however, the removal of all in situ fluids and any gases adsorbed onto a formation, such as coal, are fully displaced so that CO2 can be adsorbed. This is theoretically and practically impossible, and any volume estimated in this manner cannot be considered as a resource for storage.

For saline-water-bearing formations, a capillary-trapped minimum water saturation (irreducible water saturation) in the presence of CO2 will likely define the maximum CO2 saturation possible for a given formation.

For oil reservoirs, the maximum possible CO2 saturation should include an irreducible water saturation and residual oil saturation to CO2.

For coals, this should include an irreducible water saturation in the cleat system. In enhanced oil recovery processes, this is called microscopic displacement efficiency.

For example, in an oil reservoir, the CO2-storage-resource on a unit area basis would be hπ, 1-, where h is net thickness in feet, π is effective porosity as a fraction of the bulk volume, Swirr is the irreducible water saturation, and Sor is the residual oil saturation. Dissolution of CO2 in the remaining oil and gas should be considered.

The risk classifications of CO2 storage capacity should also account for the reduction in accessible storage volume due to well locations and interval completions, reservoir heterogeneity that reduces volumetric sweep efficiency, and spill points of structural geologic traps.

Acknowledgments

The concepts within this paper were developed under Contract No. DE-FC26-03NT41994 with the US Department of Energy/National Energy Technology Laboratory and Contract No. Dev03-2 with the Illinois Clean Coal Institute/Illinois Department of Commerce and Economic Opportunity. The authors thank John Goodwin, Lindsey Martin, and Mary Cha with the ISGS for assistance in preparing this article.

References

- Frailey, S.M., and Finley, R.J., “CO2 Sequestration Capacity Classification,” Fourth Annual Conference on Carbon Capture and Sequestration, Presentation 64, Alexandria, Va., May 2-5, 2005.

- Guidelines for Application of Petroleum Reserves Definitions, SPEE, Houston, 1998.

- Guidelines for Evaluation of Petroleum Reserves and Resources, SPE, Dallas, 2001.

- Harrell, D.R., et al., “Oil and Gas Reserves Estimates,” JPT, September 2005, (summary of “Panel: Oil and Gas Reserves Estimates,” Paper No. OTC 17714, OTC, Houston, May 2-5, 2005.)

- Bradshaw, J., et al., “CO2 Storage Capacity Estimation: Issues and Development of Standards,” 8th International Conference on Greenhouse Gas Control Technology (GHGT-8), Trondheim, Norway, June 19-21, 2006.

The authors

Scott M. Frailey is a senior reservoir engineer with the Illinois State Geological Survey in Champaign, Ill. His primary responsibility is in CO2 geologic sequestration including enhanced oil and coalbed methane recovery with CO2. He previously worked at Texas Tech University and BP PLC. Frailey has degrees in petroleum engineering from the University of Missouri-Rolla.

Robert J. Finley is a principal geologist with the Illinois State Geological Survey in Champaign, Ill. He is the project director for a multiyear study of CO2 sequestration and heads the Energy and Earth Resources Center. Previously, he worked at the Bureau of Economic Geology in Austin. His graduate degrees are in geology from Syracuse University and the University of South Carolina.

T. Scott Hickman is president of T. Scott Hickman & Associates Inc., a Midland, Tex., based reservoir engineering firm. Hickman received a BS in petroleum engineering from Texas Tech University and an MS in petroleum engineering from Louisiana Tech. He has served as president of both SPE and SPEE.